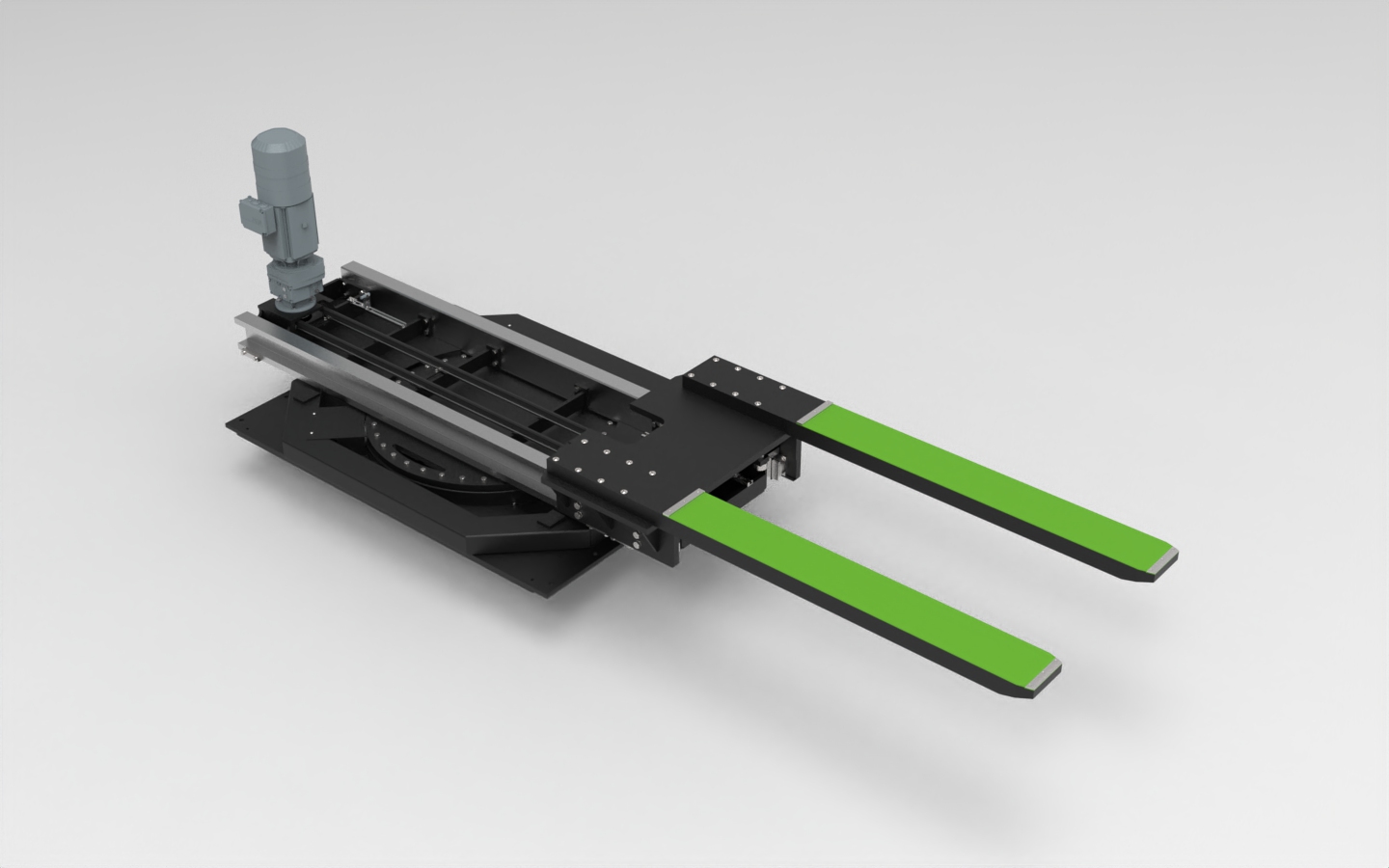

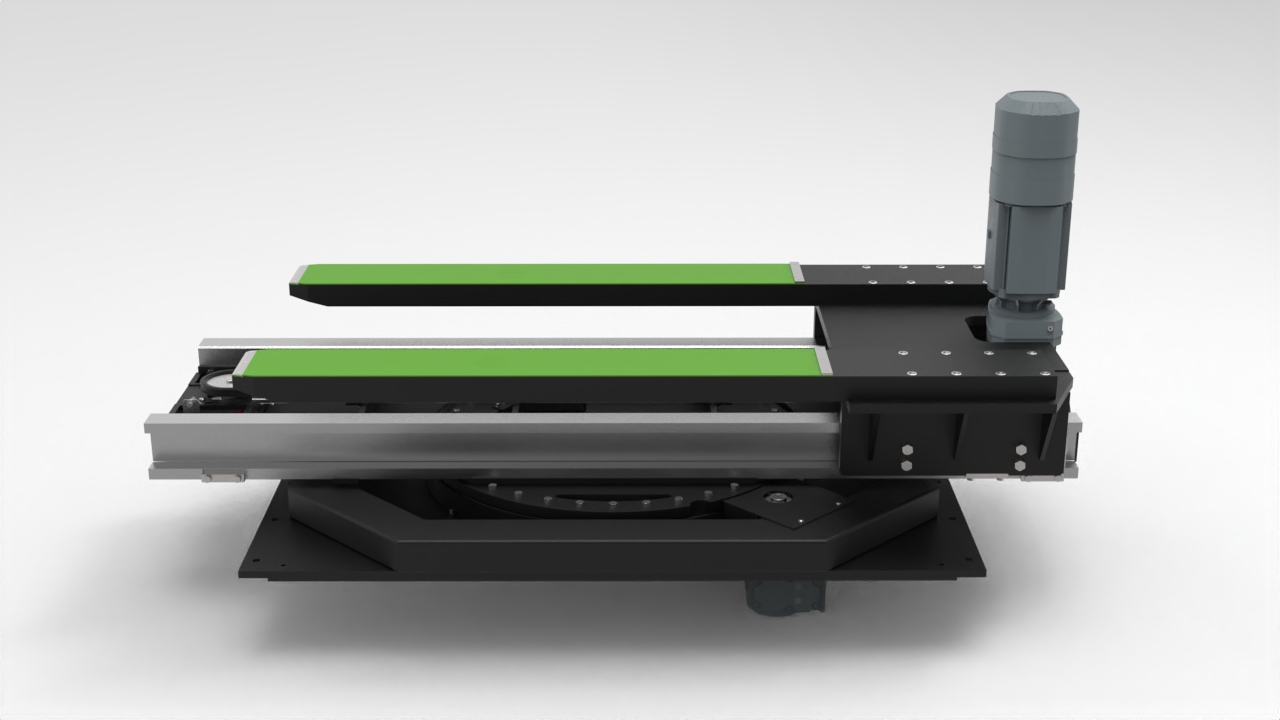

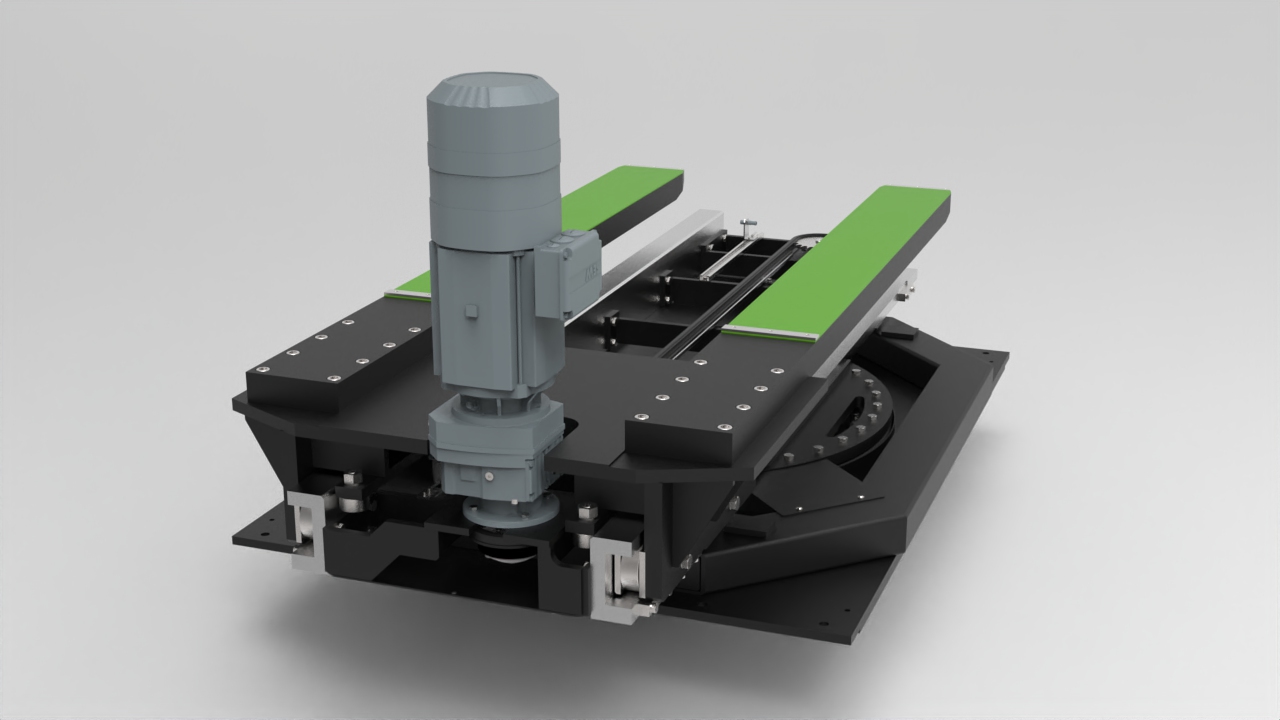

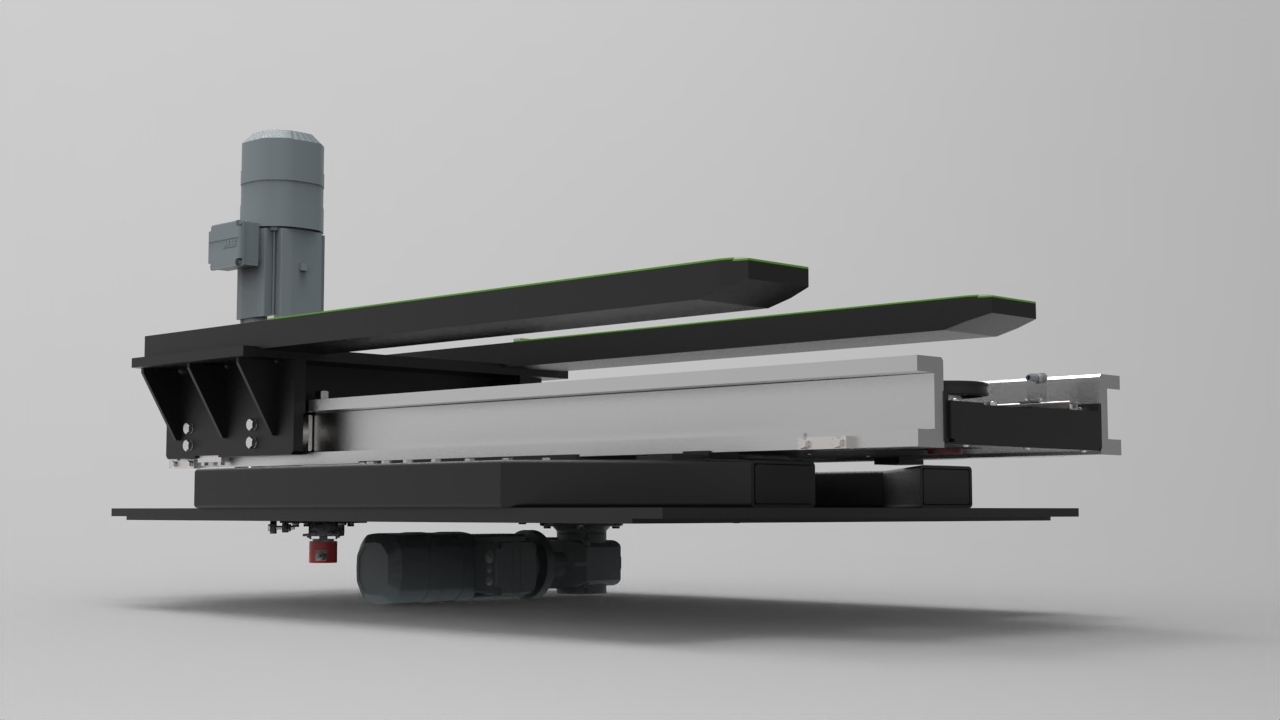

Rotary pushing fork for the automatic storage of cradles

Rotary pushing fork for the transverse storage of cradles in the automotive industry

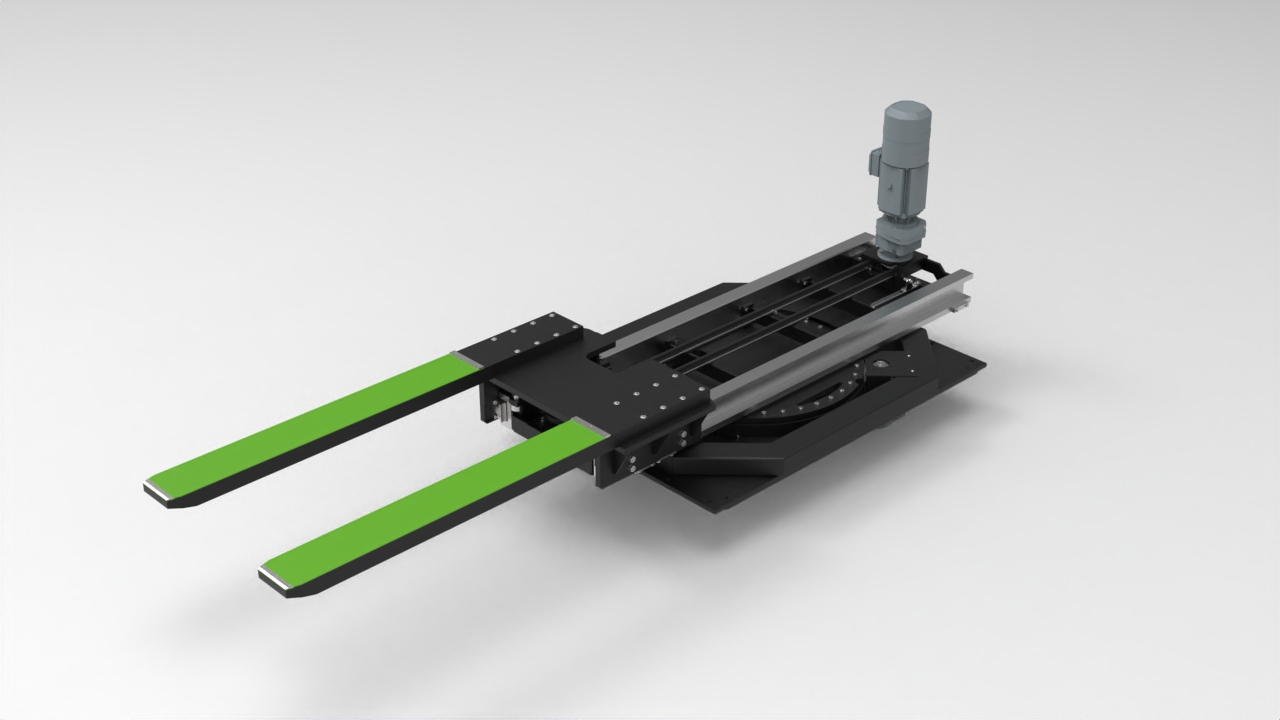

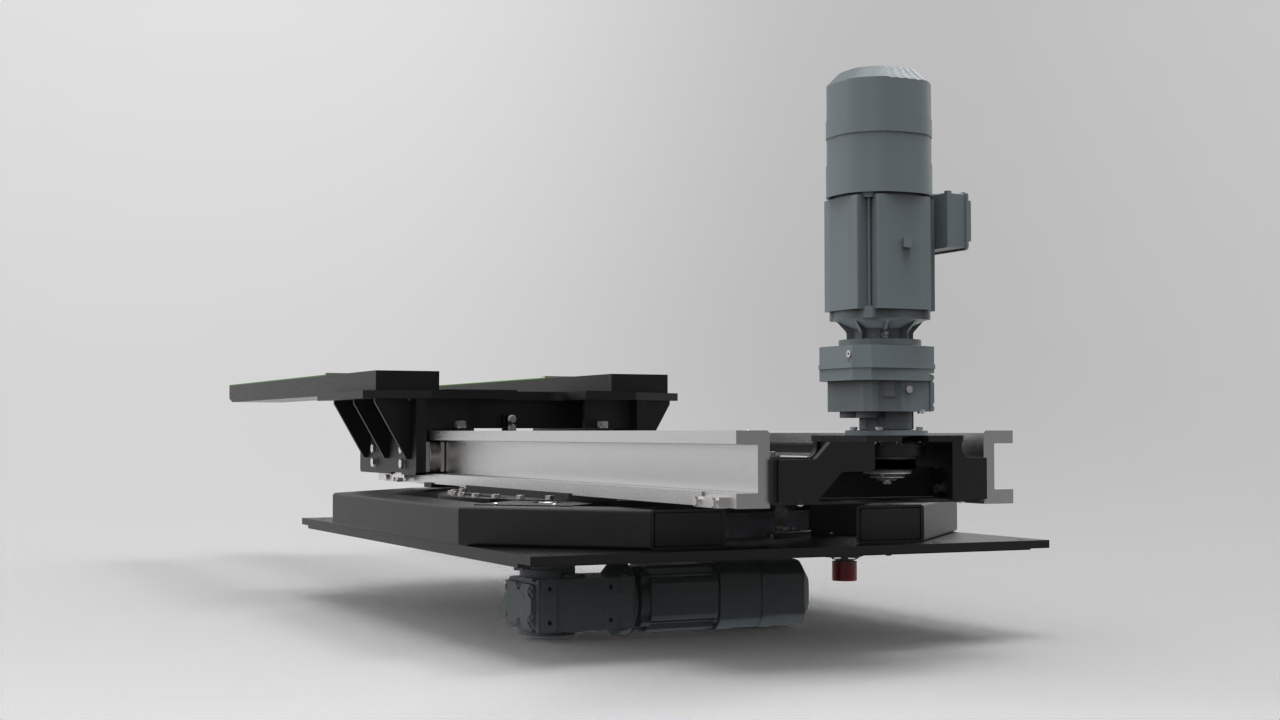

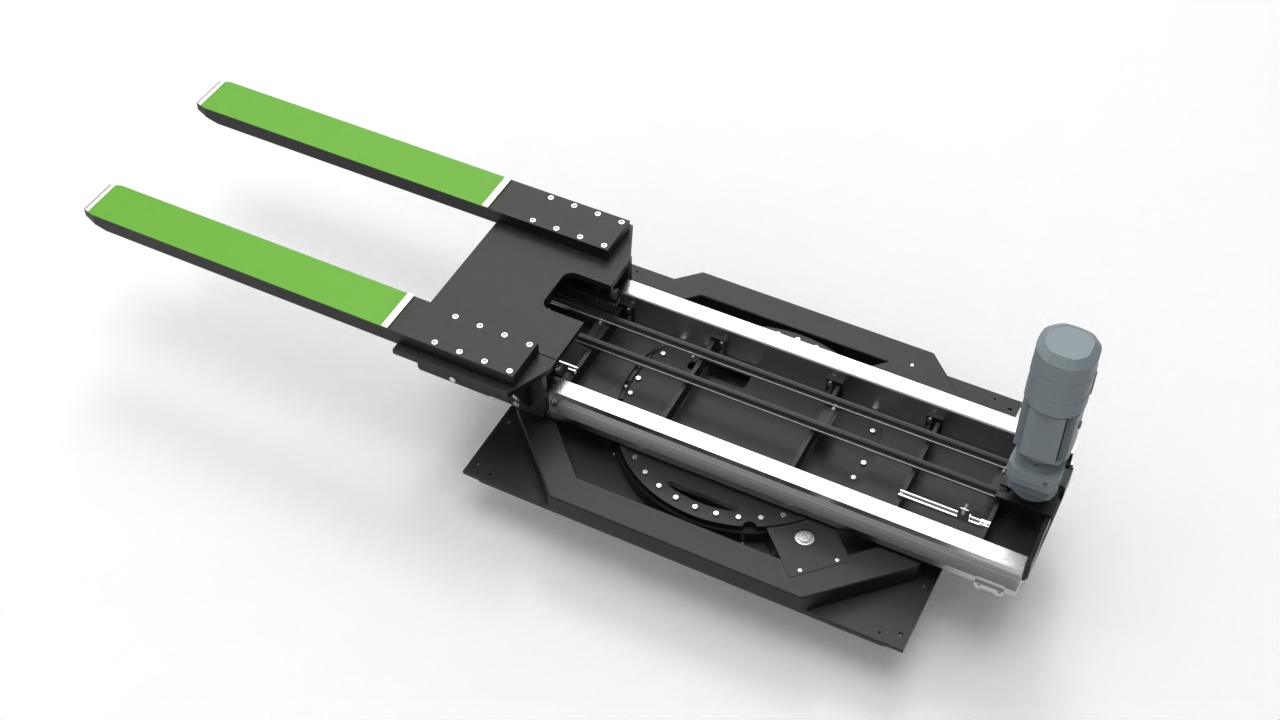

The DSG 2.0-2200 rotary pushing fork has been specially developed for the storage and retrieval of cradles at a commercial vehicle manufacturer. As the cradles have only limited and closed entry windows, our machine is the best choice for the customer’s intralogistics processes. The high load to be transported and the low entry window for the prongs are easily mastered by our AFB rotary pushing fork. It offers a low extending cross-section with a high payload of 2 t at the same time.

Rotation function for storage on both sides

In the automatic warehouse of the commercial vehicle manufacturer, two-sided storage is possible thanks to the practical turning function of the rotary pushing fork. The turning diameter is specially designed to ensure that turning is possible without any problems while the stacker crane is in motion. The AFB rotary pushing fork also impresses with its ease of maintenance. Particularly low maintenance components support the durability of our machines.

Technical data:

-

Load: Cradles

-

Load weight: 2.000 kg

-

Length of the prongs: 1.855 mm

-

Stroke: 1.700 + 30 mm

-

Length of the unit: 2.200 mm

-

Width of the unit: 1.240 mm

-

Rotation diameter: 2.263 mm

-

Rotation angle: 180°

-

Rotation time (unloaded / loaded): 3 s / 11 s