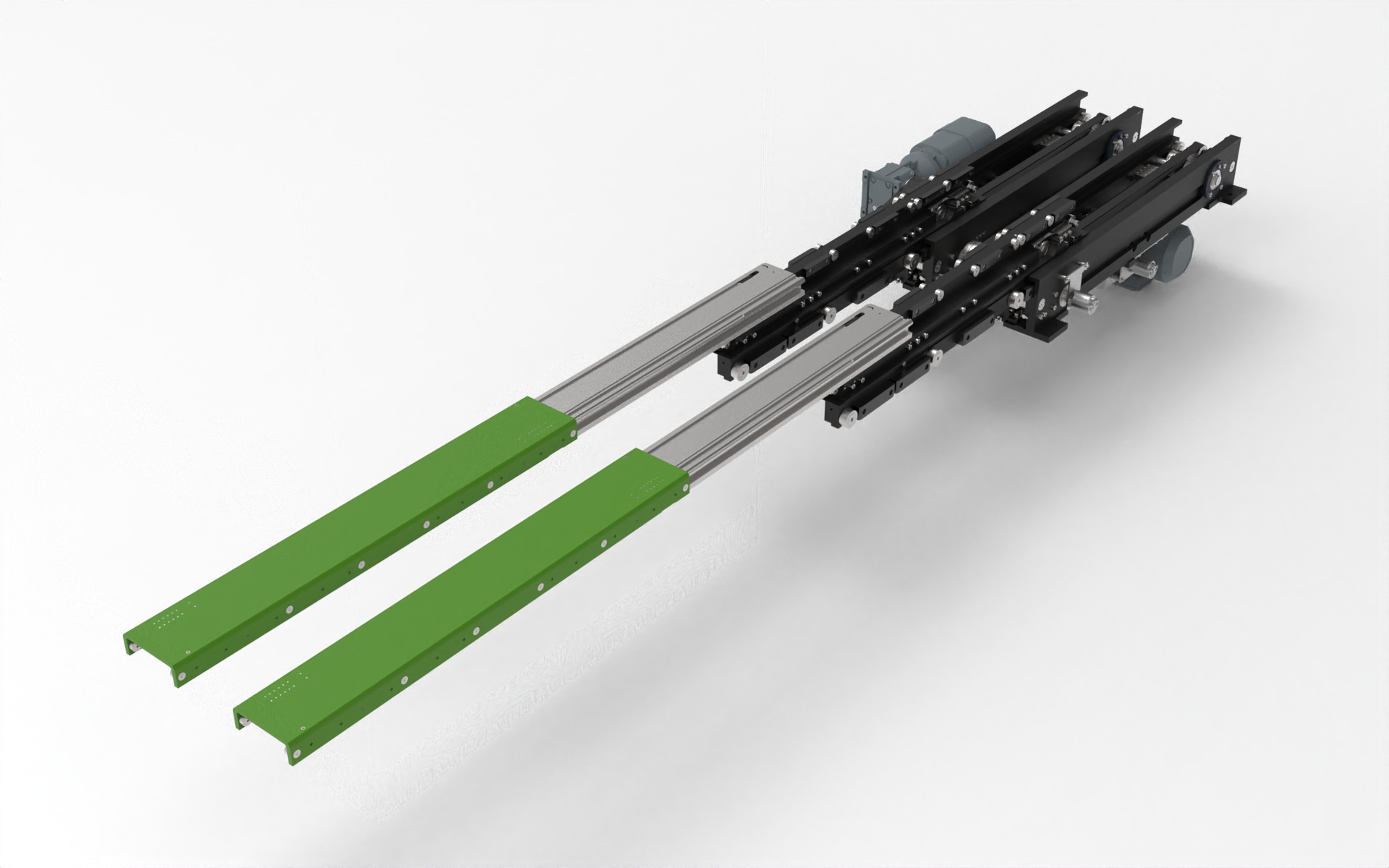

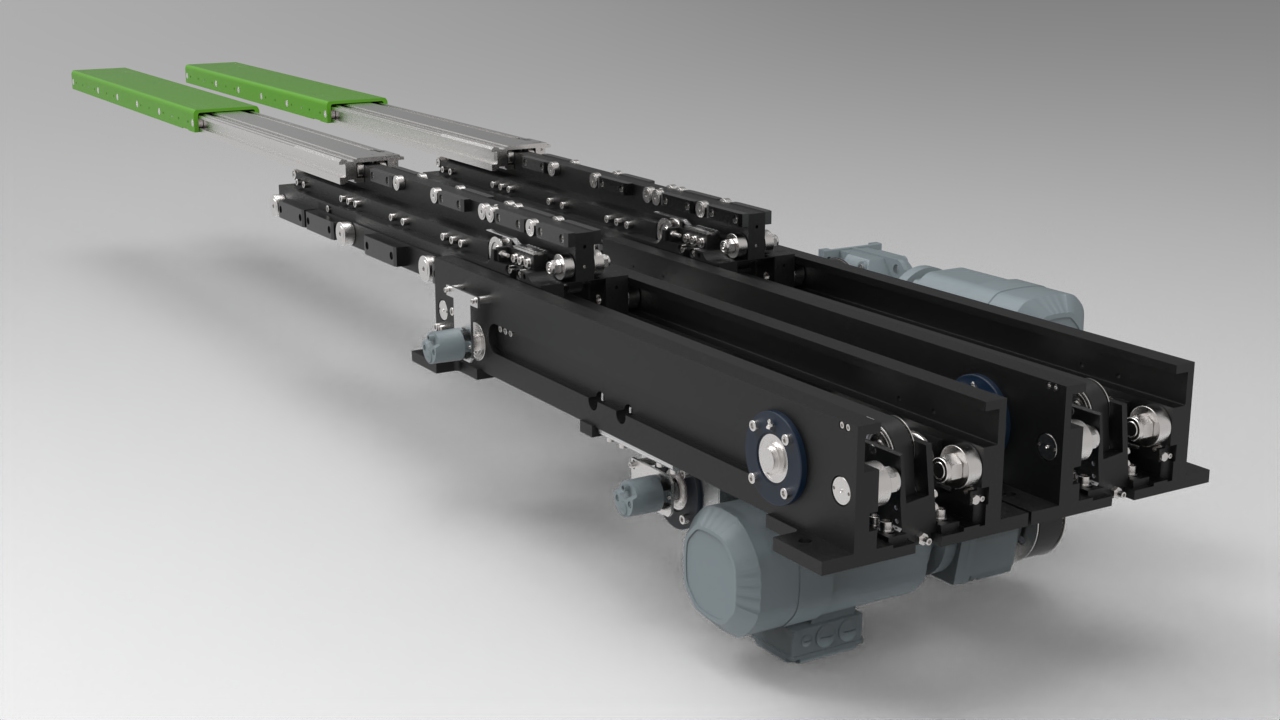

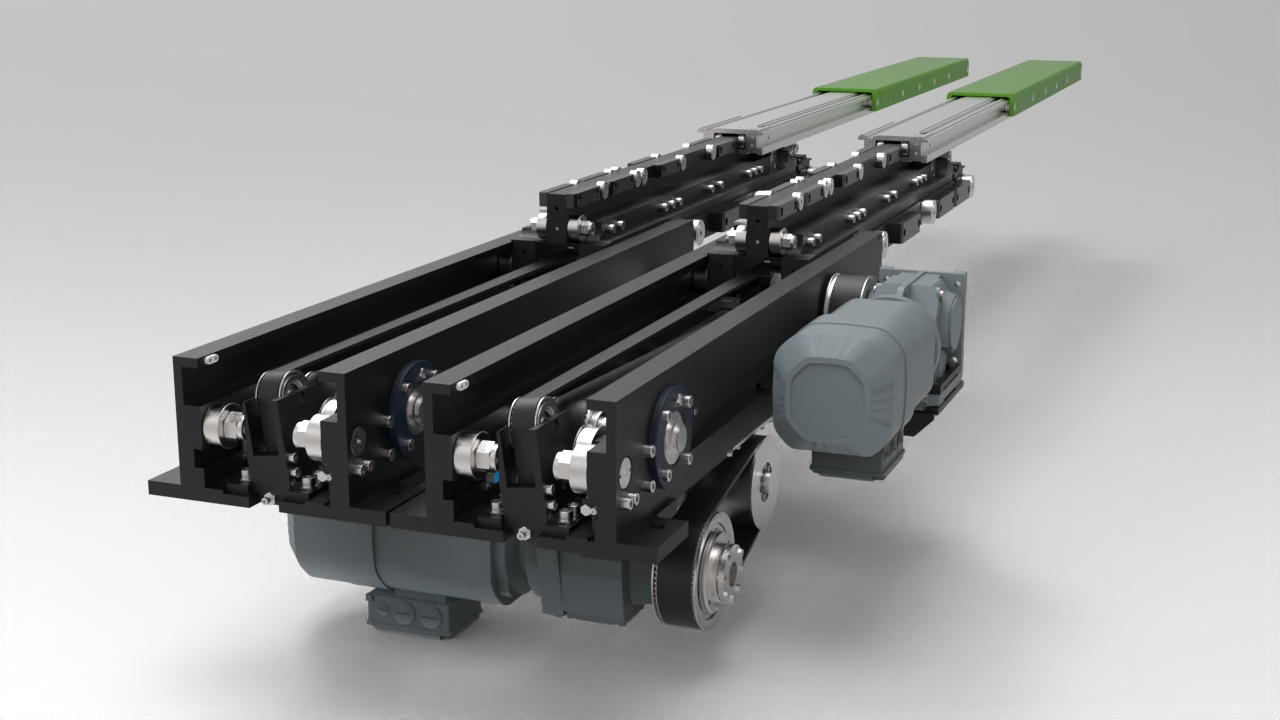

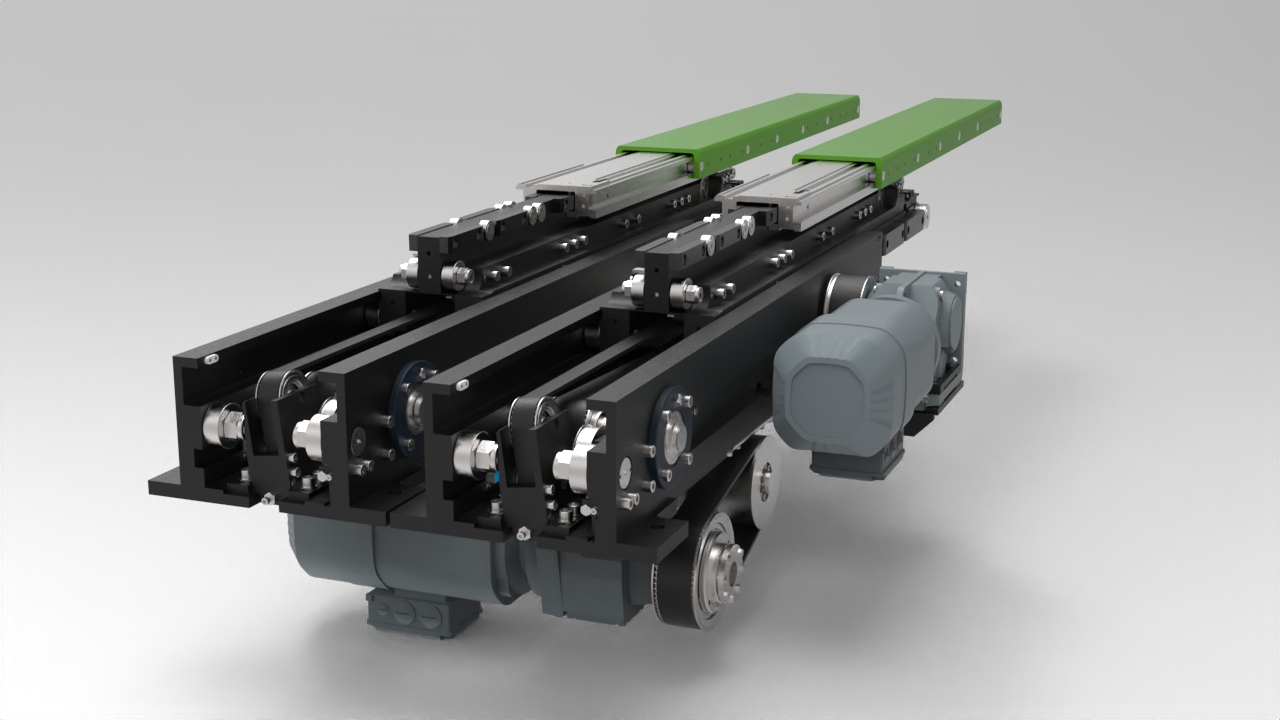

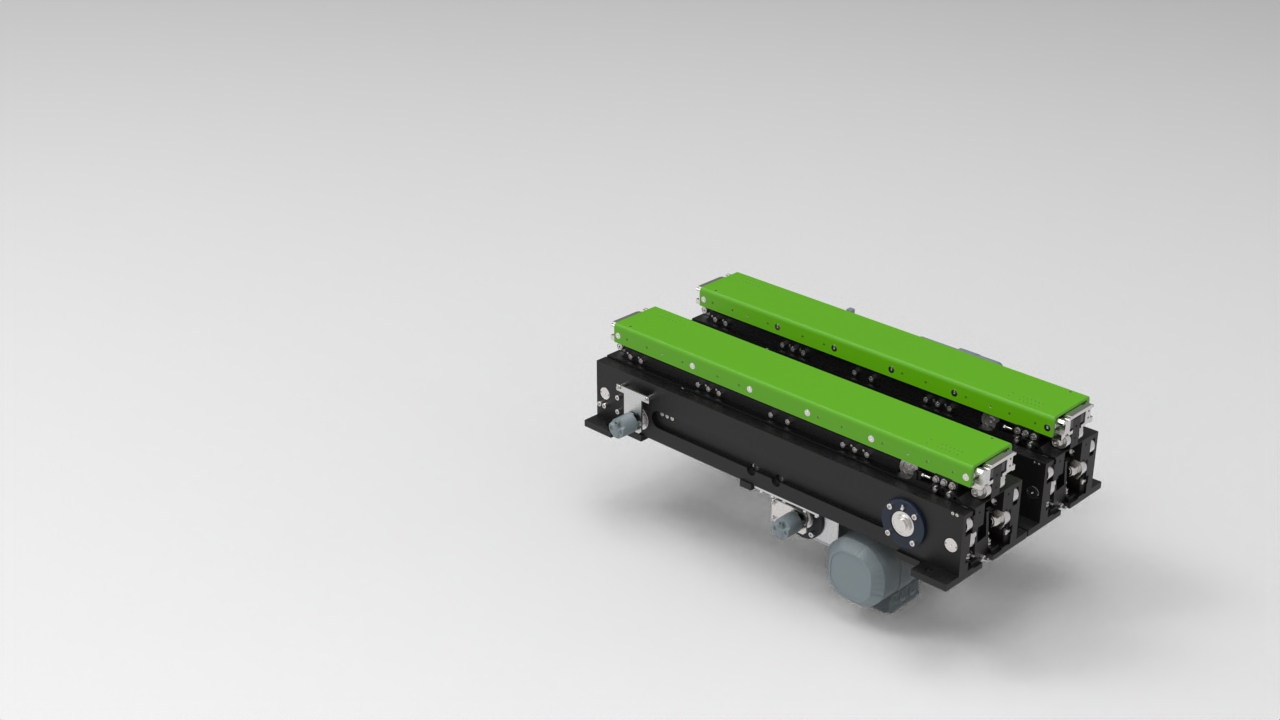

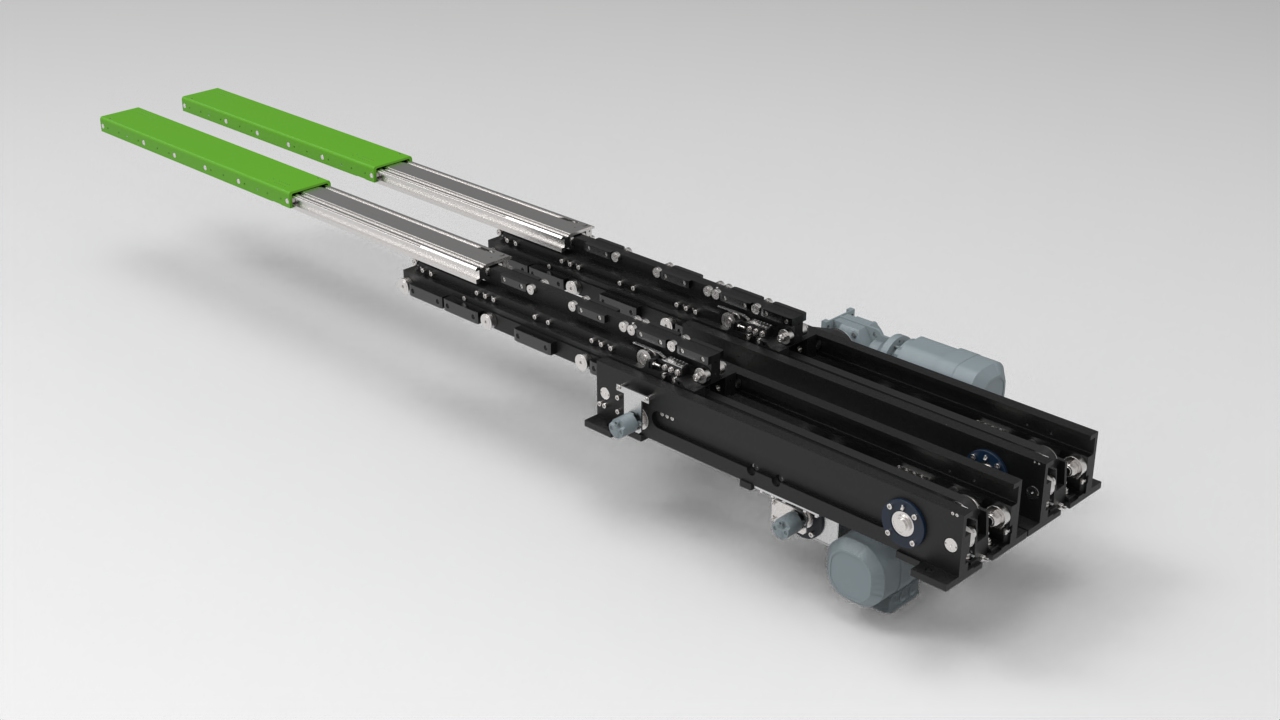

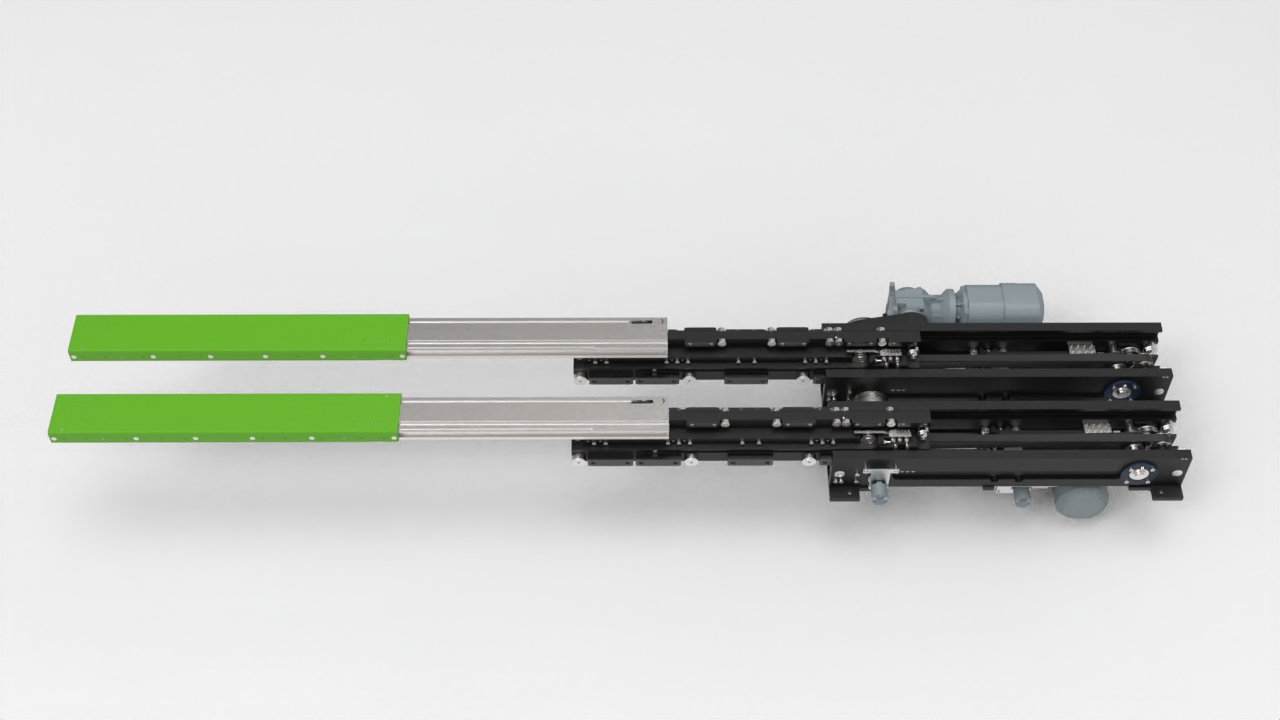

Market launch of the D3/2-R65-180-1300 telescopic fork with belt drive

The time has come: our telescopic fork D3/2 with belt drive is launched on the market. After an intensive planning and test phase as well as 24 h/7 continuous testing, the “D3/2 Belt edition” is ready to handle important intralogistical transport processes faster, better and more successfully. The telescopic fork is suitable for multi-deep storage, where all profiles can be moved together or in steps via two drive units. From the entire planning phase through testing to market readiness, we were able to gain important knowledge for improvments of the device.

Compared to the previous model “D3/2” with chain drive, we have improved the positioning accuracy by using efficient belt technology so that load carriers can be picked up and stored even more reliably with the new telescopic fork. Tolerances during the handover of the load are thus optimised. At the same time, safety distances can be significantly reduced. Another significant advantage of the “D3/2 belt edition” is the up to 20 % reduction in self-weight. In addition, the belt drive enables significantly higher speeds and better acceleration. This reduces the cycle time enormously. The use of a special belt with increased durability also reduces significantly the maintenance intervals compared to telescopic forks with chain drive, since, for example, the “chain elongation” during the start-up phase is no longer necessary.

The advantages at a glance:

-

Self-weight reduced by up to 20 %

-

Higher speeds and accelerations possible

-

Better positioning accuracy

-

Increased durability of the drive system

-

More maintenance-friendly

Technical data:

-

Load weight: 1.000 kg

-

Stroke 1st position: 1.400 + 50 mm

-

Stroke 2nd postion: 2.800 + 41 mm

-

Acceleration unloaded: 3 m/s

-

Speed unloaded: 120 m/min

-

Length of the top fork: 1.250 mm

-

Length of the unit: 1.300 mm

-

Self weight of the complete unit (without motors): approx 800 kg