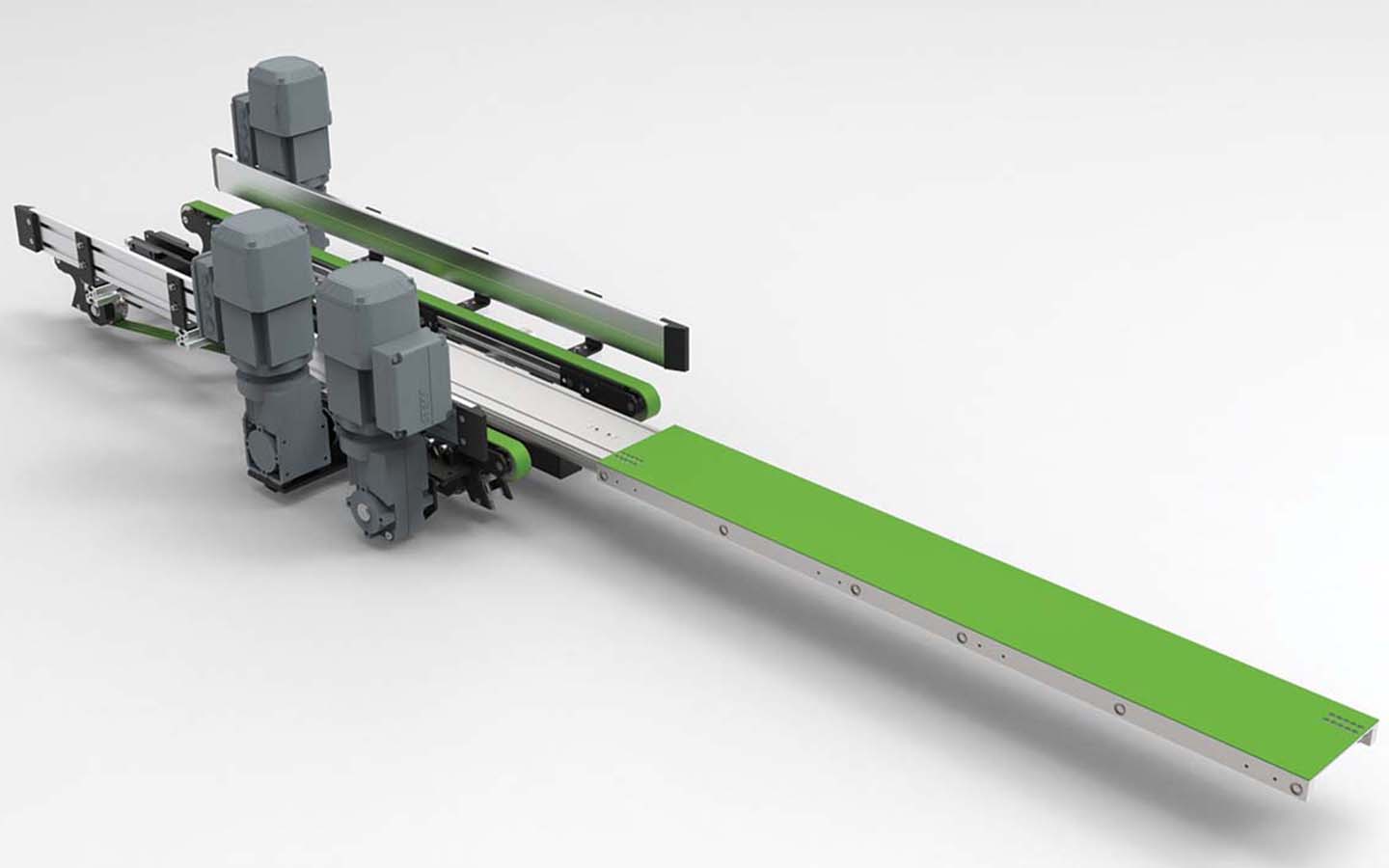

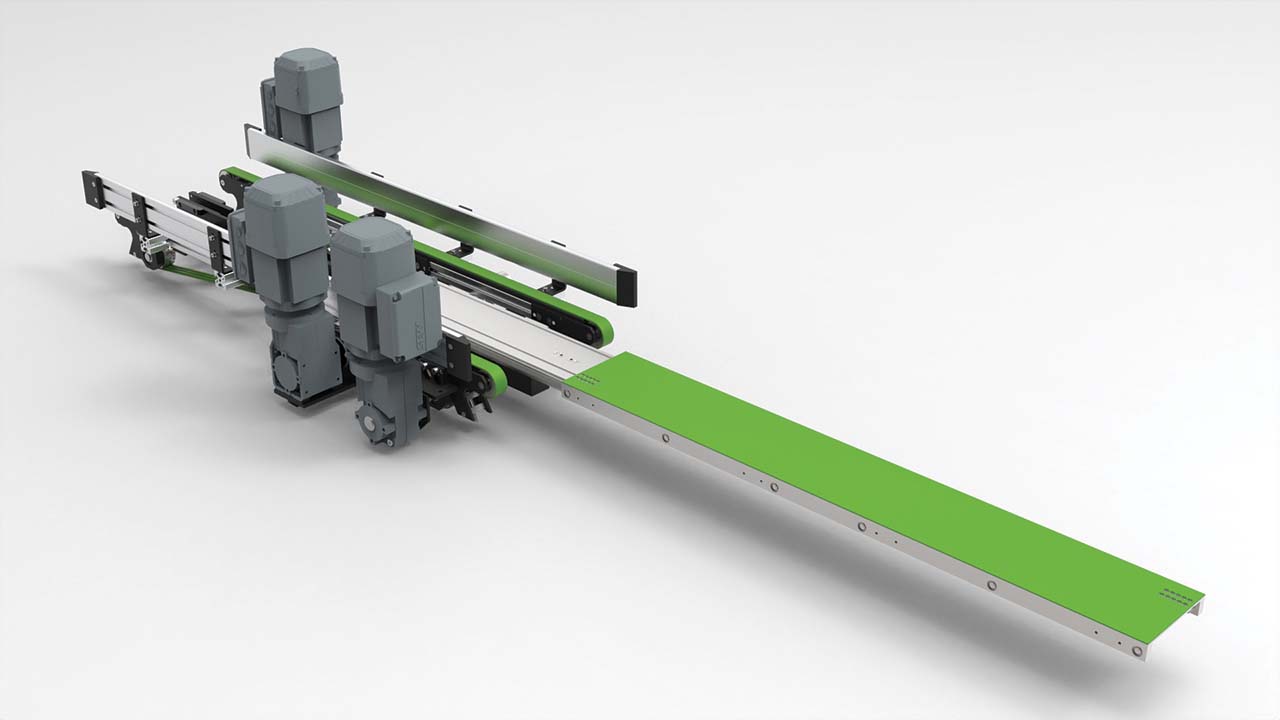

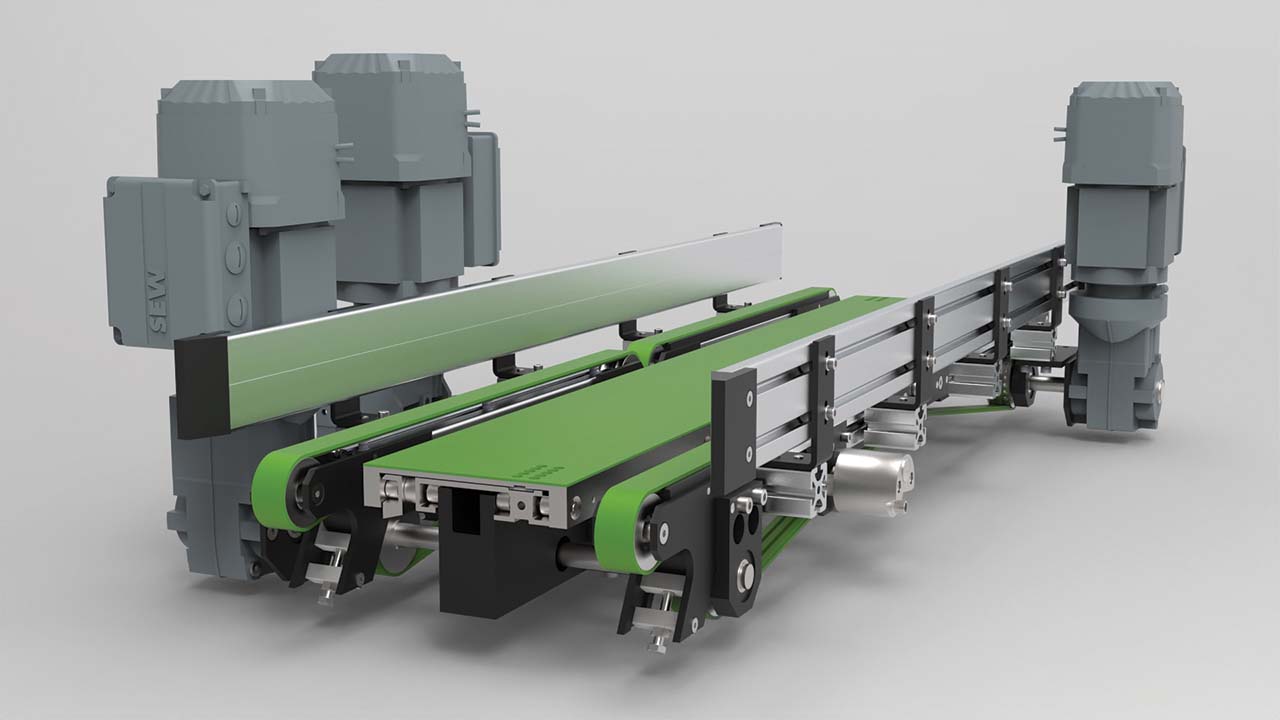

The telescopic fork for precise transport in the warehouse

Dual belt conveying for maximum flexibility

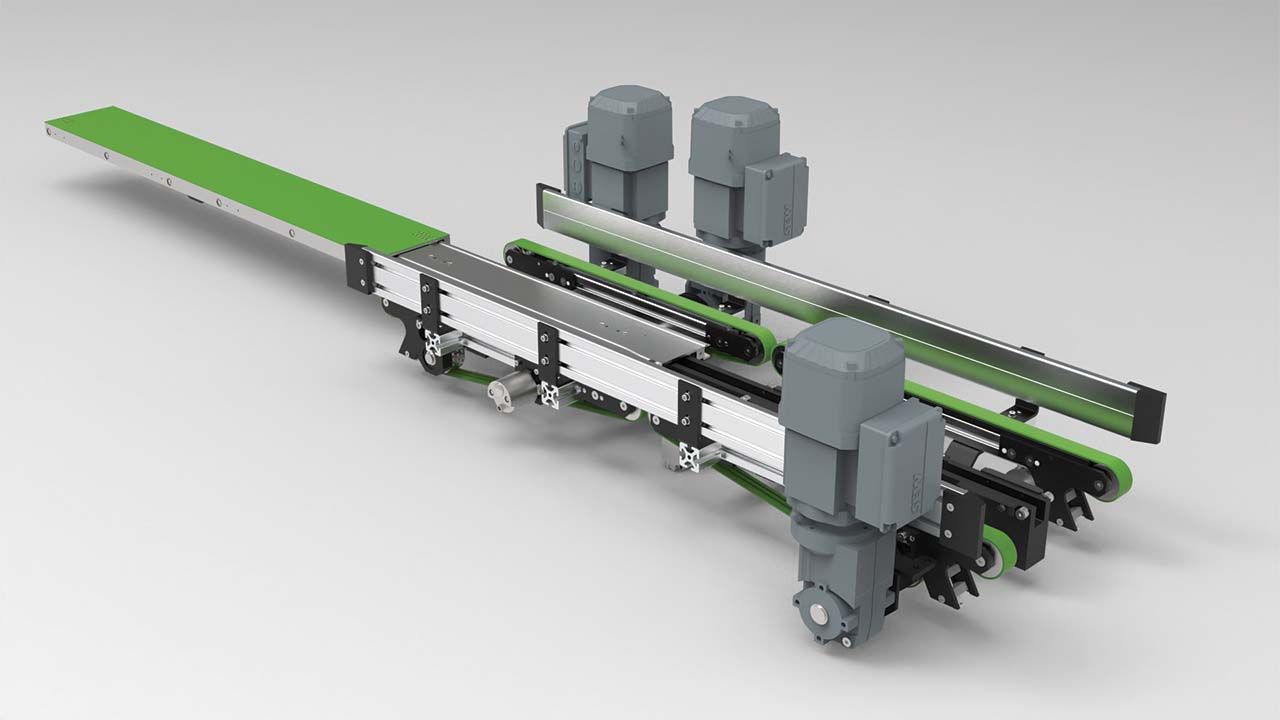

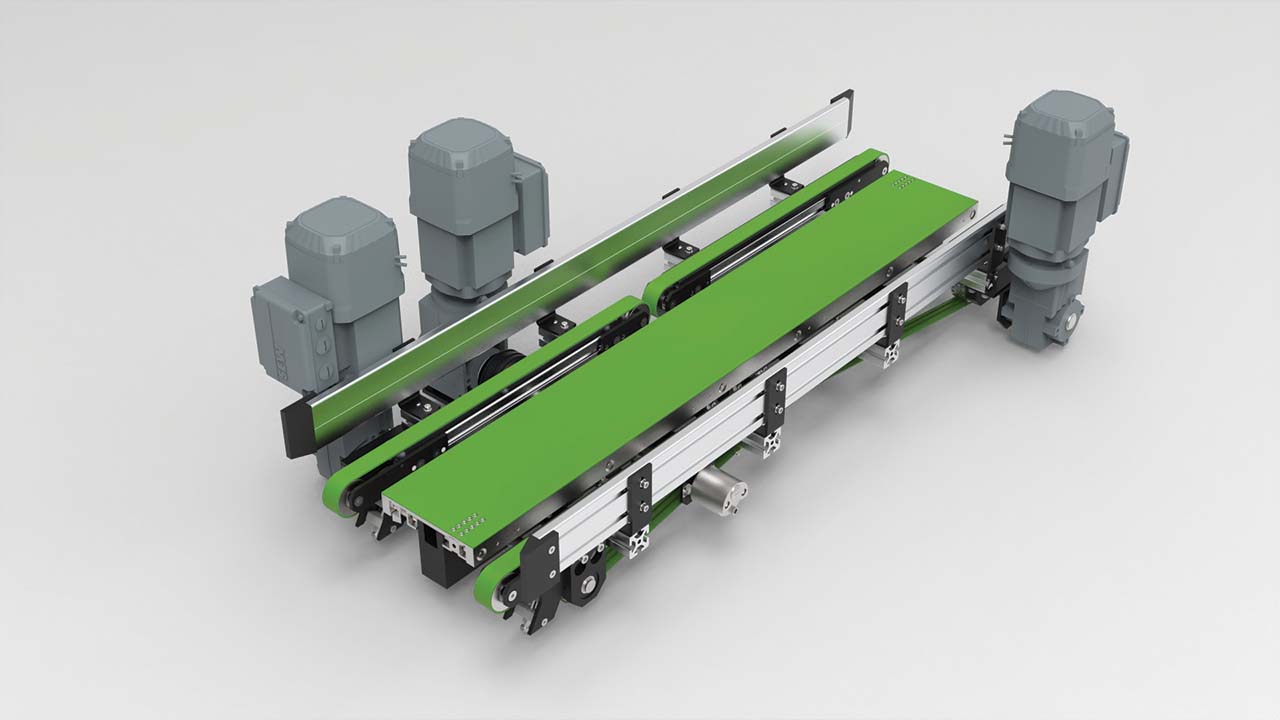

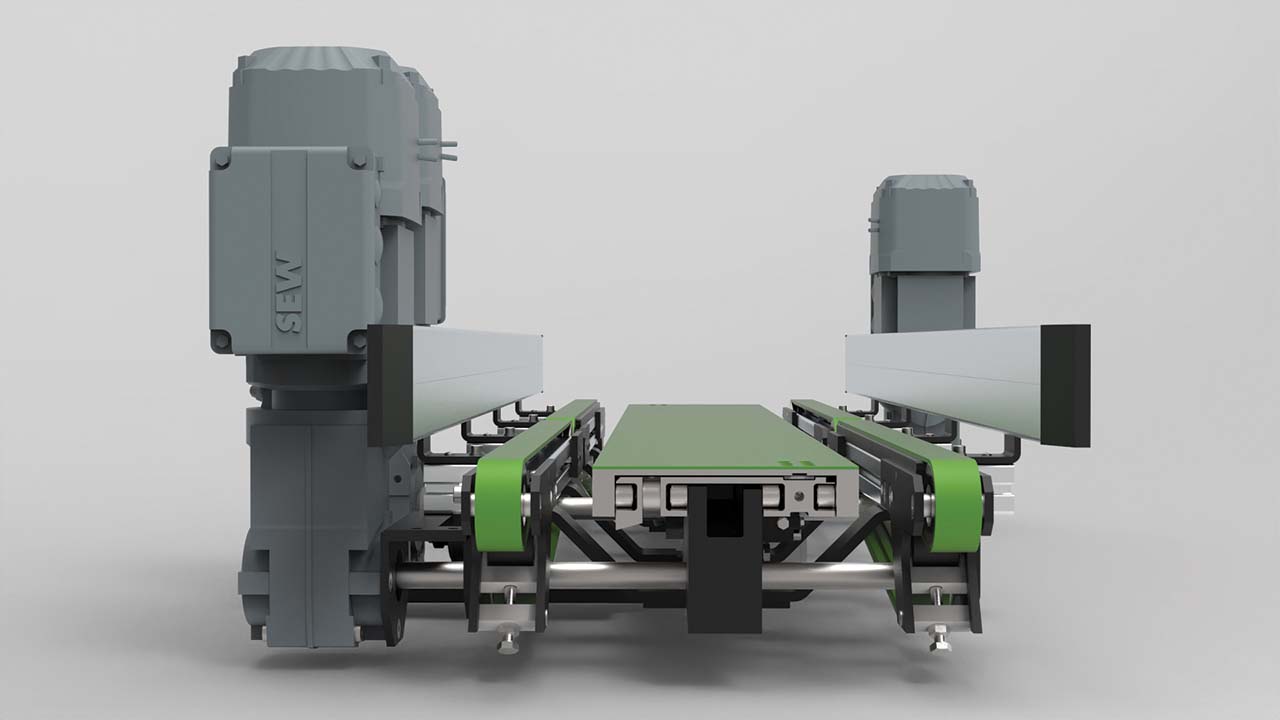

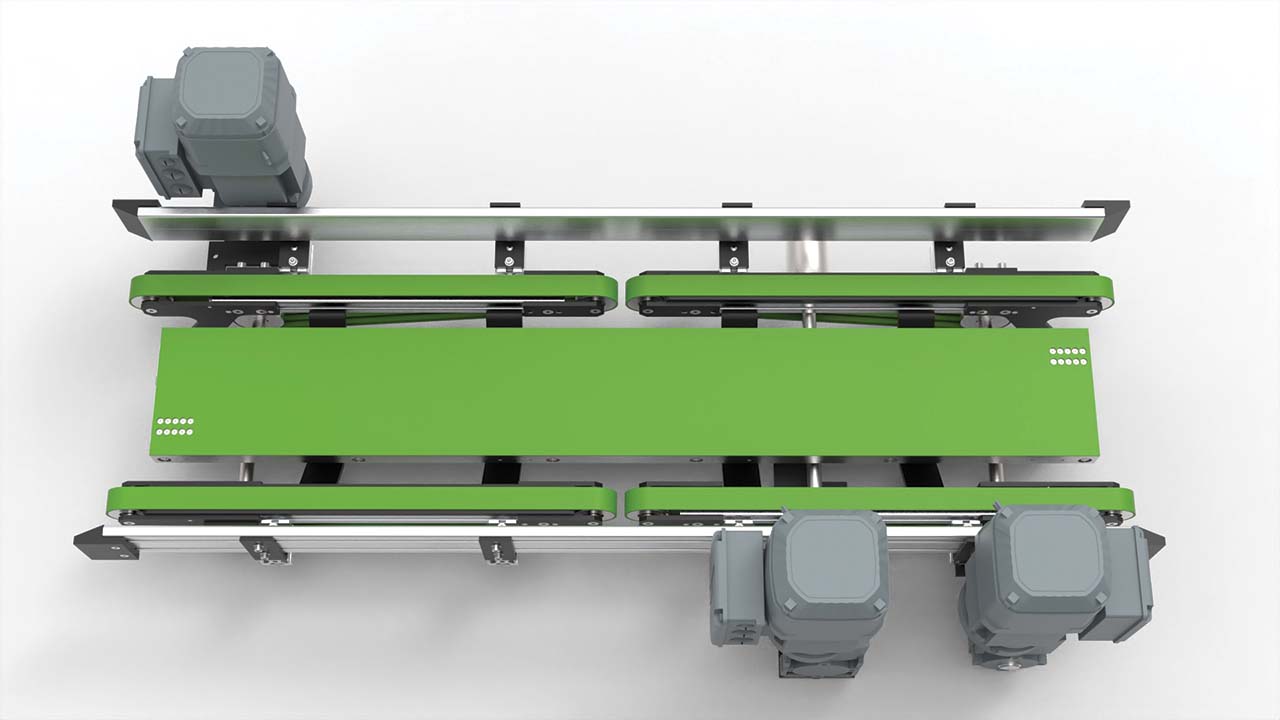

Our MINILOAD telescopic fork R32ST-180-N-1250 has a high quality steel design with belt drive. Two belt conveyors enable double-deep storage and retrieval of boxes in the automatic small parts warehouse. The top fork width of the unit has been specially adapted to safely accommodate the load. At the same time, the upper fork has a non-slip covering to safely hold and move the load during transport.

Compact and precise

The MINILOAD impresses with its compact design, which is particularly easy to install and does not require a drive box. An invaluable advantage of the device: The robust belt drive not only ensures high speeds and acceleration values, but also guarantees repeatable positioning of the telescopic fork. The two belt conveyors thus offer absolute precision in the rack aisle. The MINILOAD’s low dead weight also enables high dynamic values during transport with low energy consumption.

Low cost and low wear

Thanks to the robust drive unit, the MINILOAD telescopic fork is particularly low-wear. As a result, the device type requires significantly less maintenance and is also faster than comparable telescopic forks with a chain drive. In addition, the purchase price is lower compared to the MINILOAD in the aluminium version. Good to know: The device frame can be equipped with sensors, which then only have to be wired and adjusted.

You will find an exhibit of the MINILOAD telescopic fork at LogiMAT 2023 in Stuttgart from April 25 – 27.

Technical data:

-

Load: 100 kg

-

Belt conveyor quantity: 2

-

Stroke: 1375 + 30 mm

-

Length of the top fork: 1250 mm

-

Length of the unit: 1250 mm

-

Self weight of the complete unit: approx. 165 kg