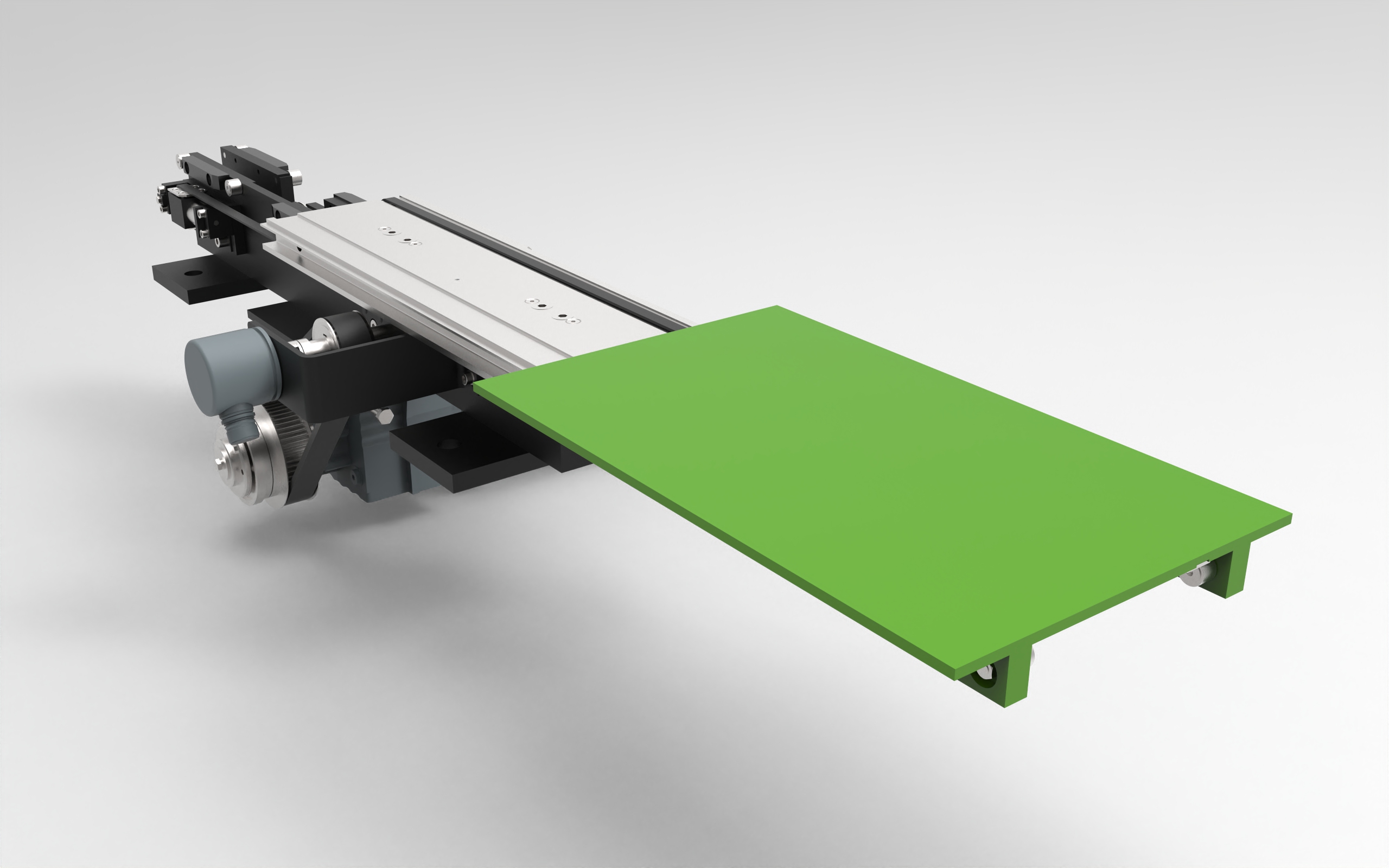

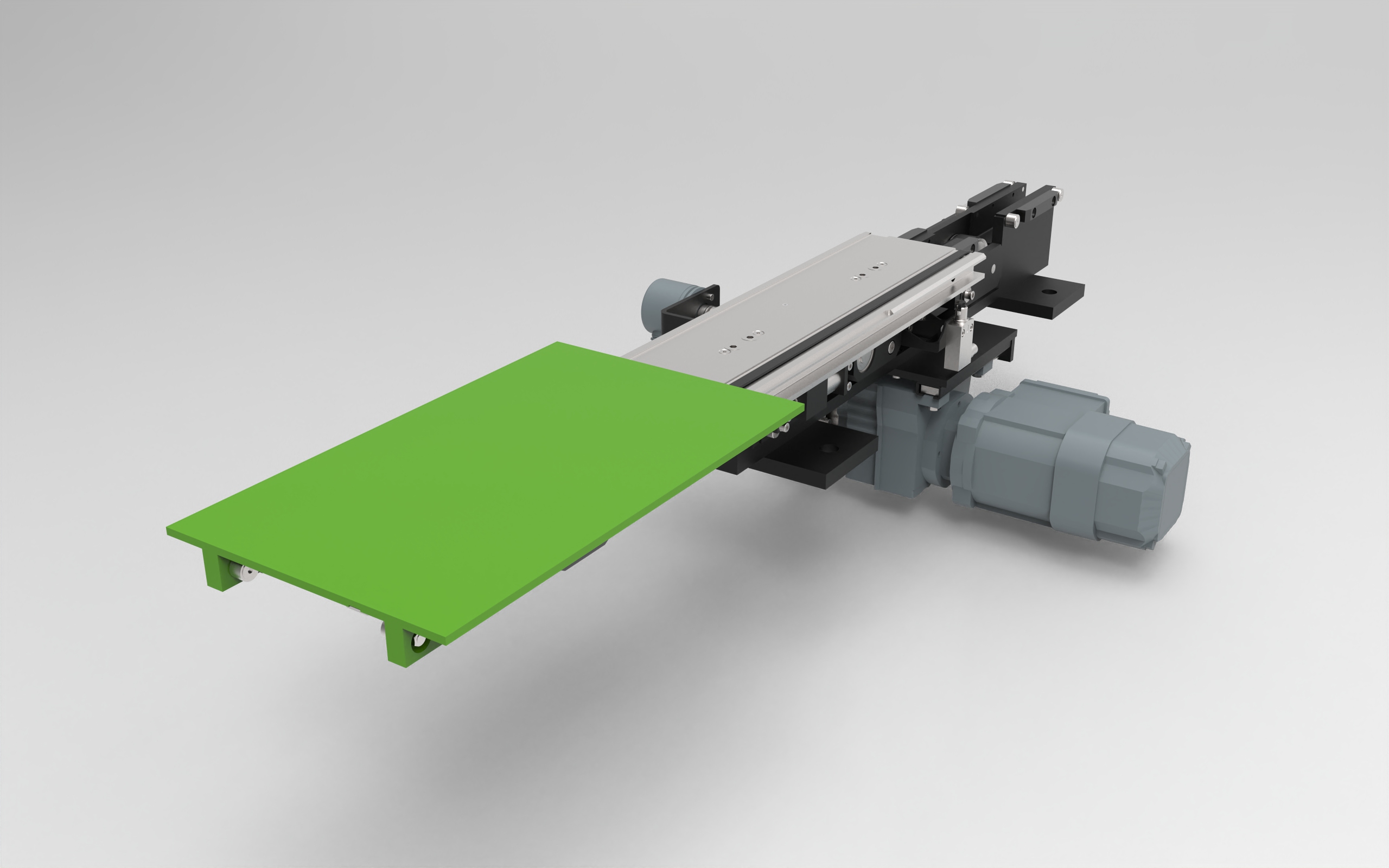

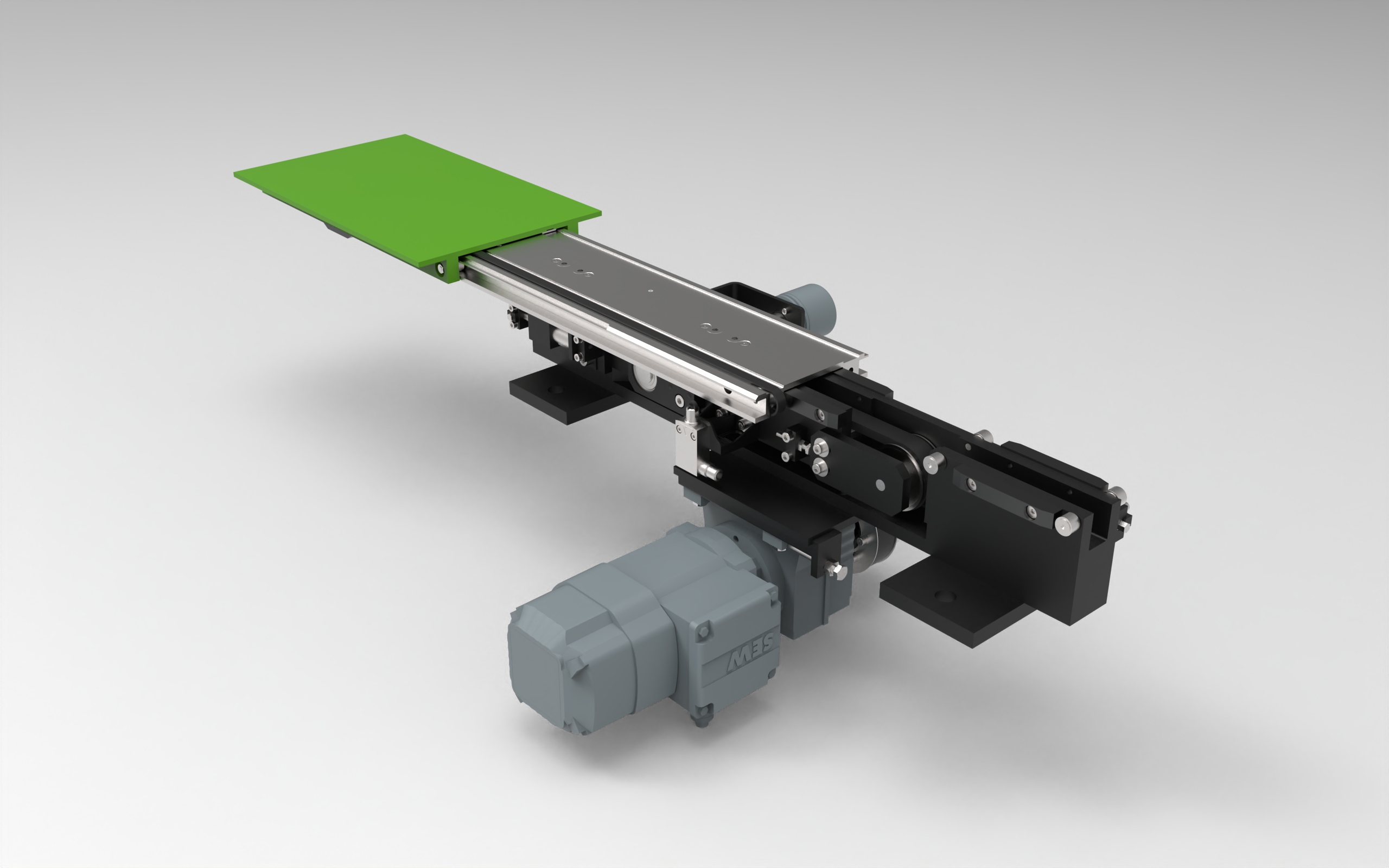

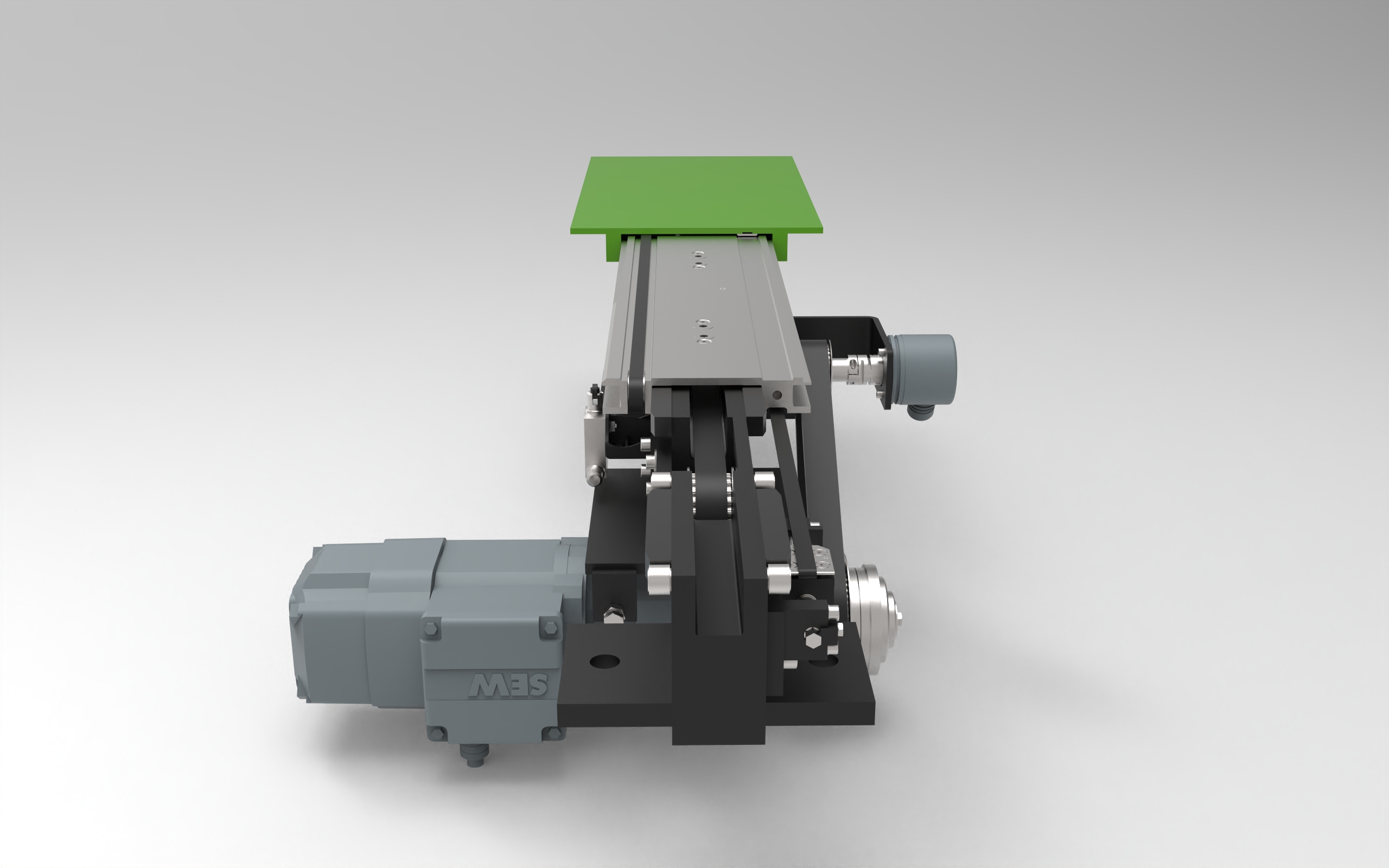

Telescopic fork with belt drive

Production automation with AFB

Telescopic fork with belt drive

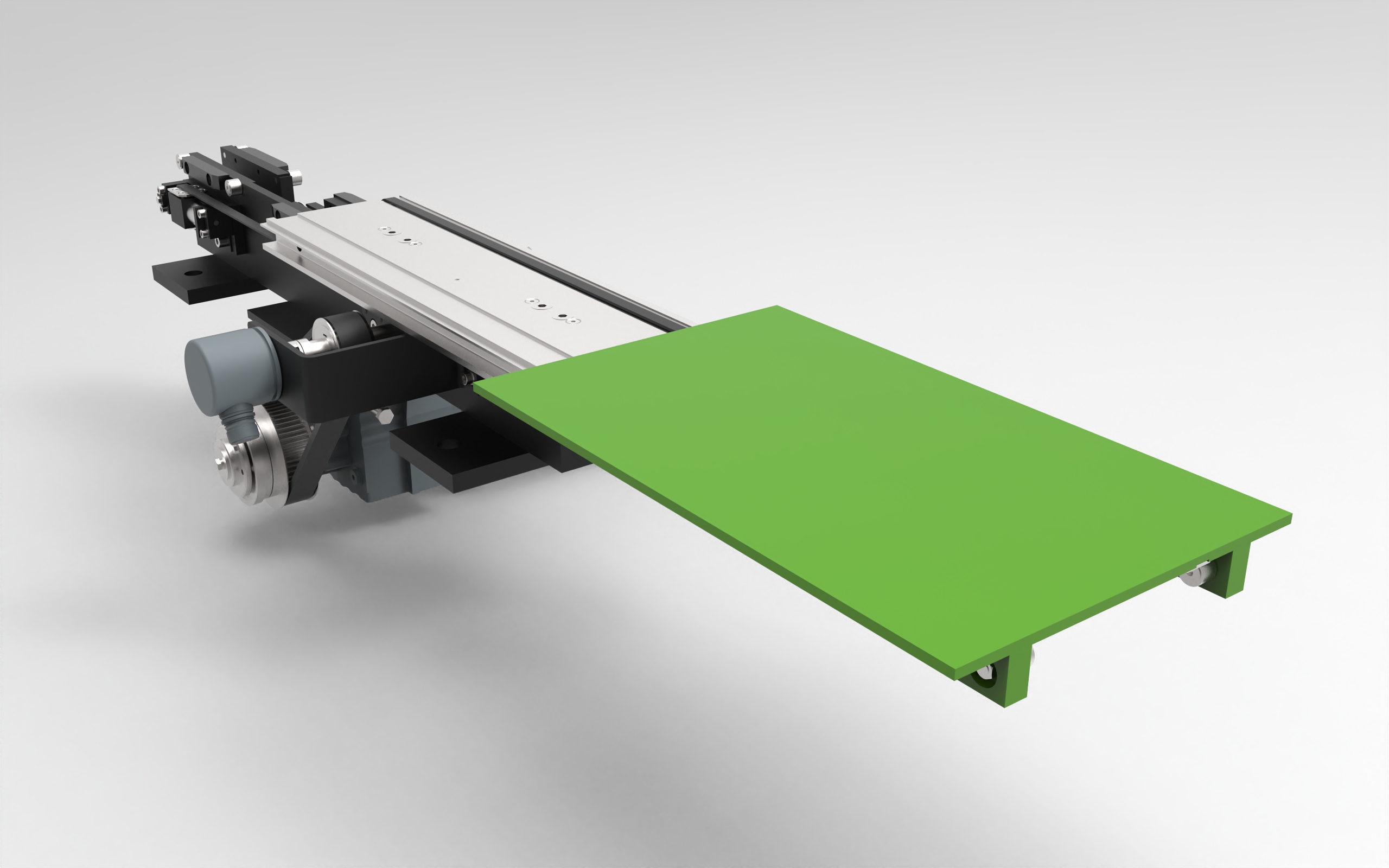

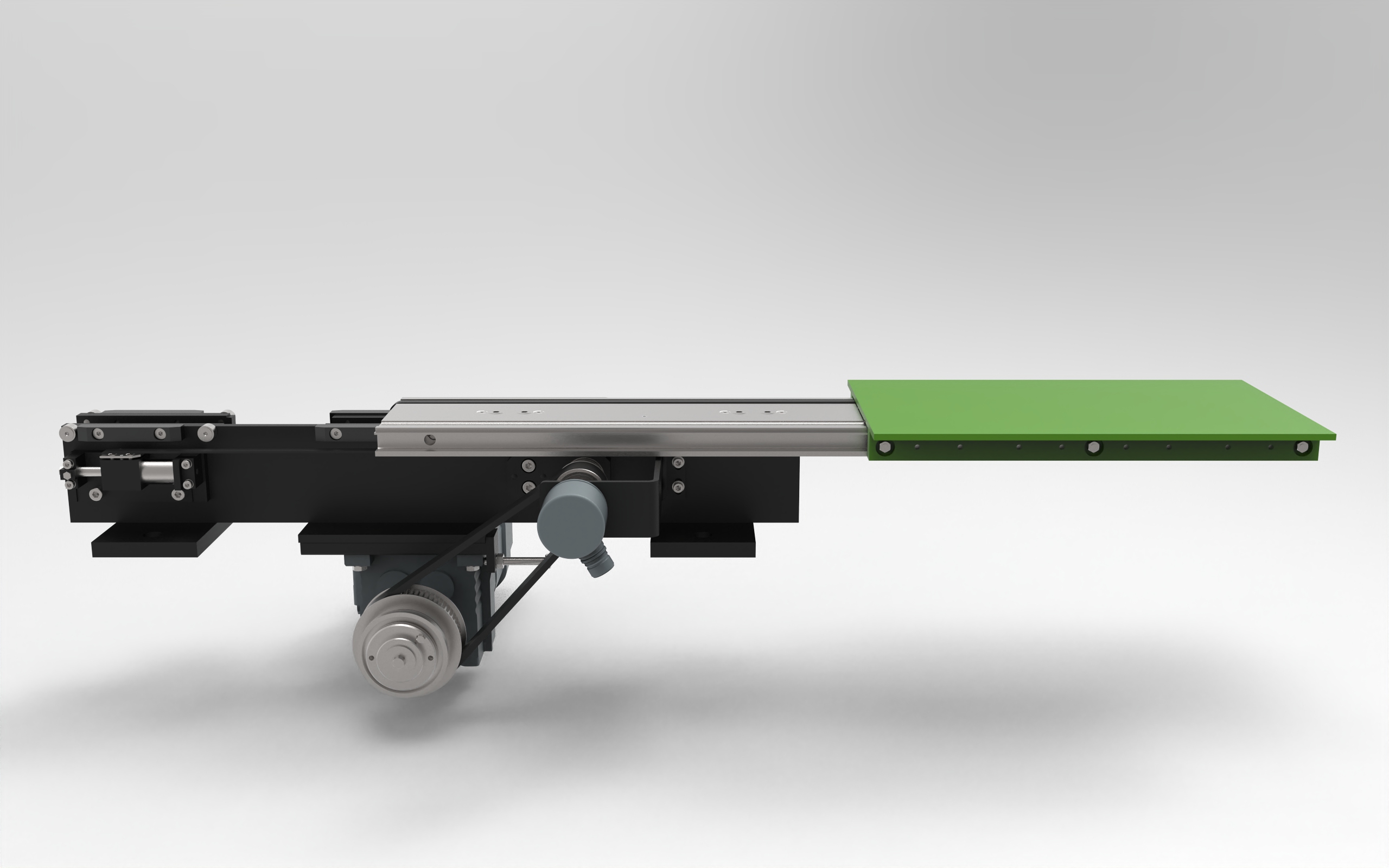

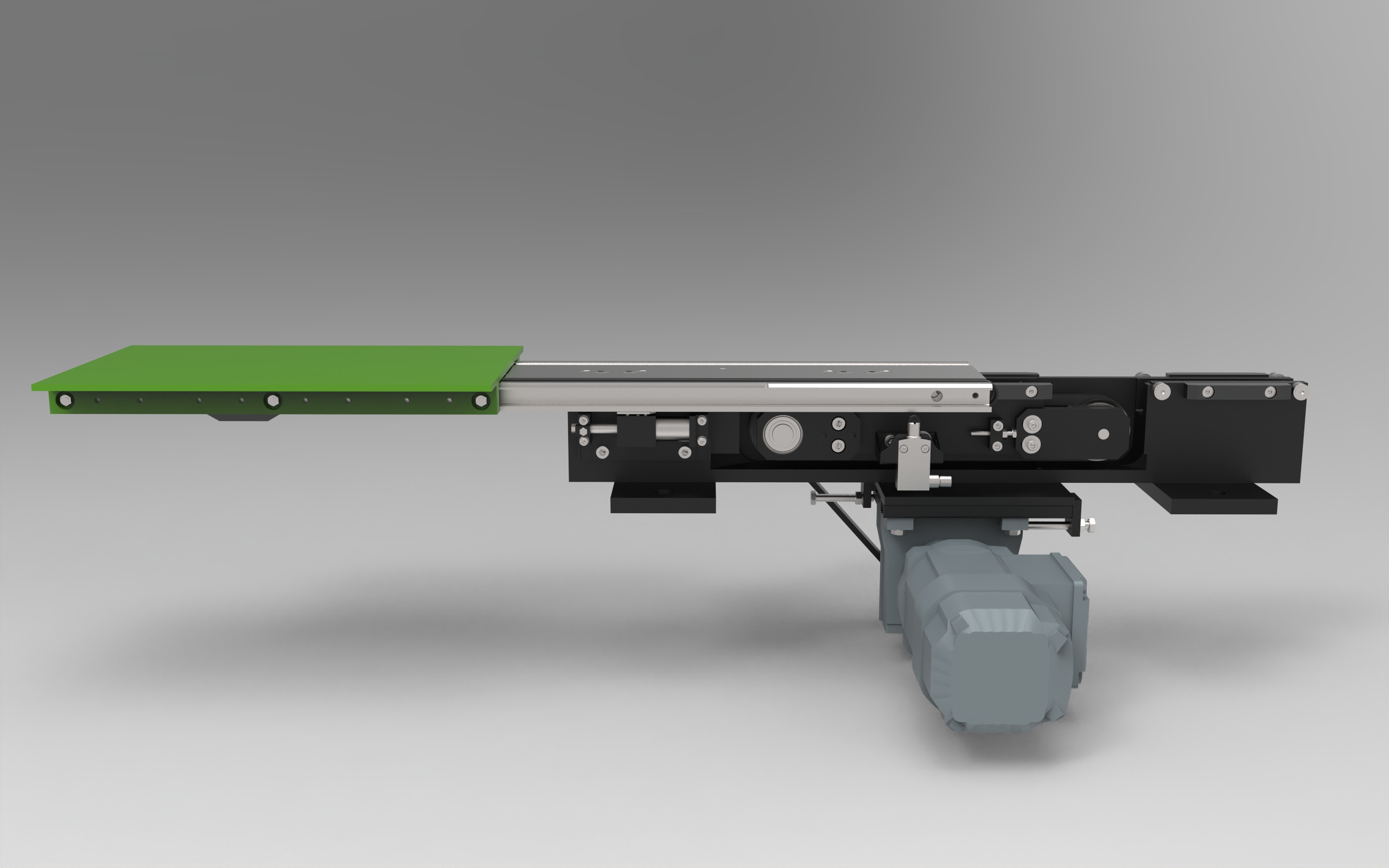

For our customer, a manufacturer of baby care products, we developed a small, compact MINILOAD telescopic fork in steel design with belt drive, on which the top fork width has been adapted for safe pick-up of the load. With this, assembly plates can now be transported uncomplicatedly and quickly in the production line. In order to be able to keep the position of the load during transport on the top fork, it was equipped with a anti-slip covering. The telescopic fork helps to optimate and automate the customer’s production flows.

Outstanding advantages of the belt drive

As the MINILOAD does not need a drive box, it can convince with its flat design. Our customer received the product as a compact unit that is particularly easy to install. Further advantages: thanks to its belt drive, the telescopic fork has a high positioning accuracy and no chain elongation can take place. At the same time, it is very low-wear thanks to the robust drive system. This means that this MINILOAD-type requires significantly less maintenance and is faster than a telescopic fork with a chain drive; in addition, it is significantly less expensive than a belt-driven MINILOAD in aluminium design.

Technical specifications:

-

Load weight: 100 kg

-

Stroke: 610 + 20 mm

-

Length of the top fork: 420 mm

-

Length of the unit: 720 mm

-

Self weight of the complete unit: approx. 60 kg