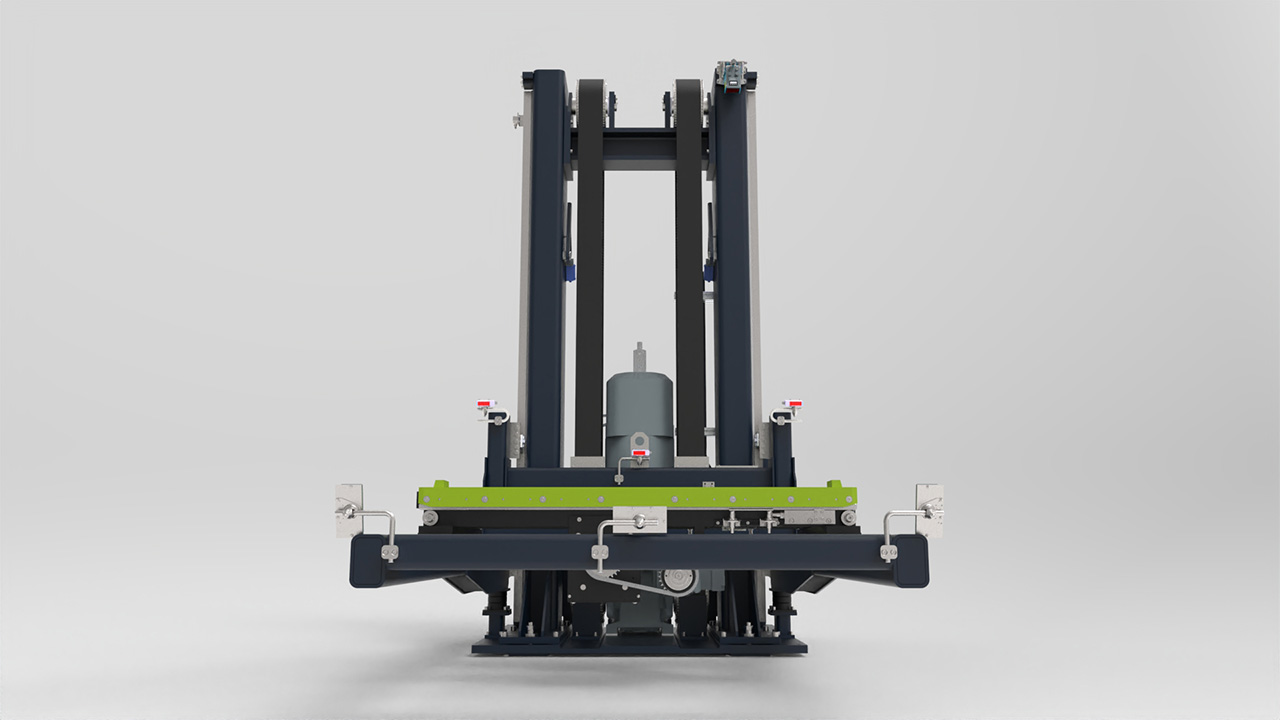

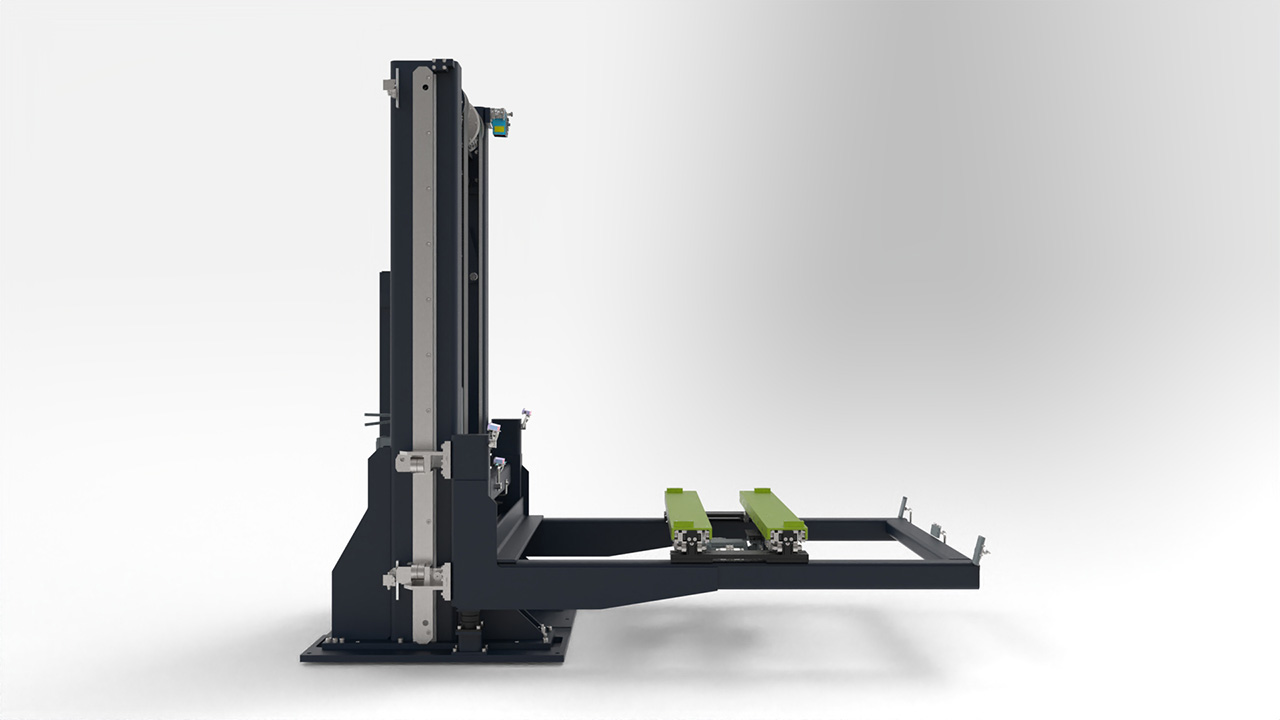

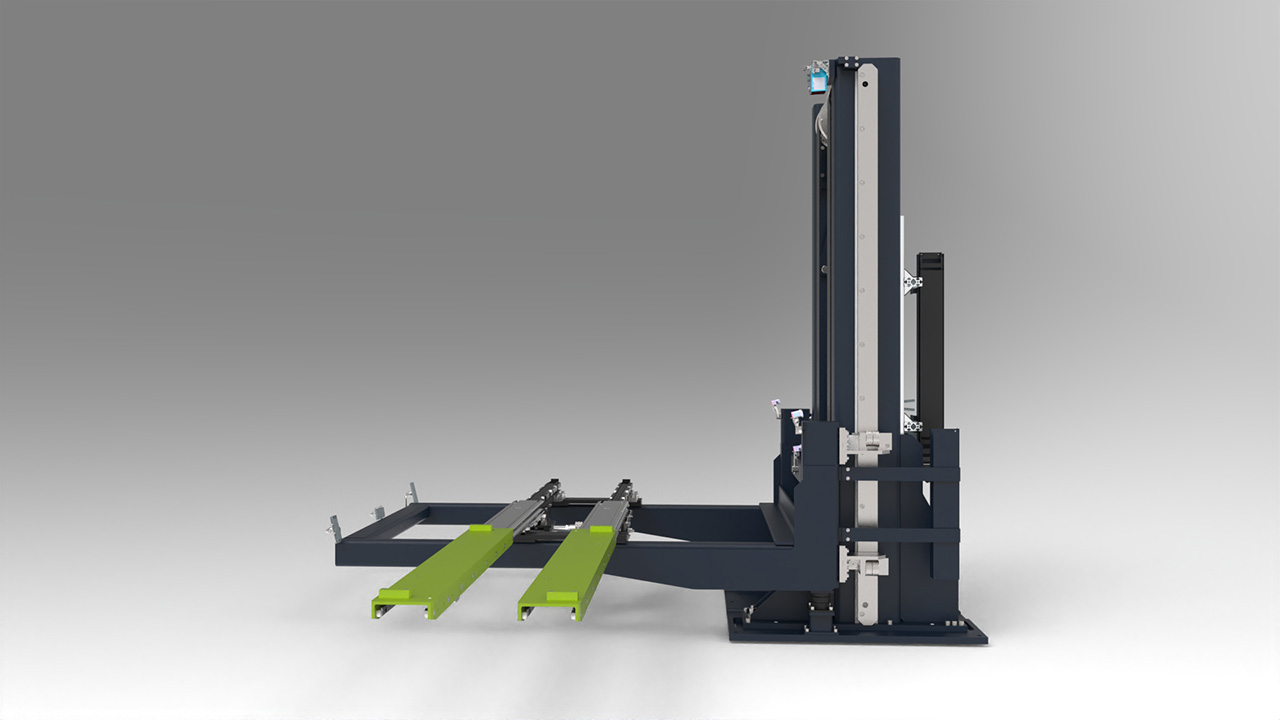

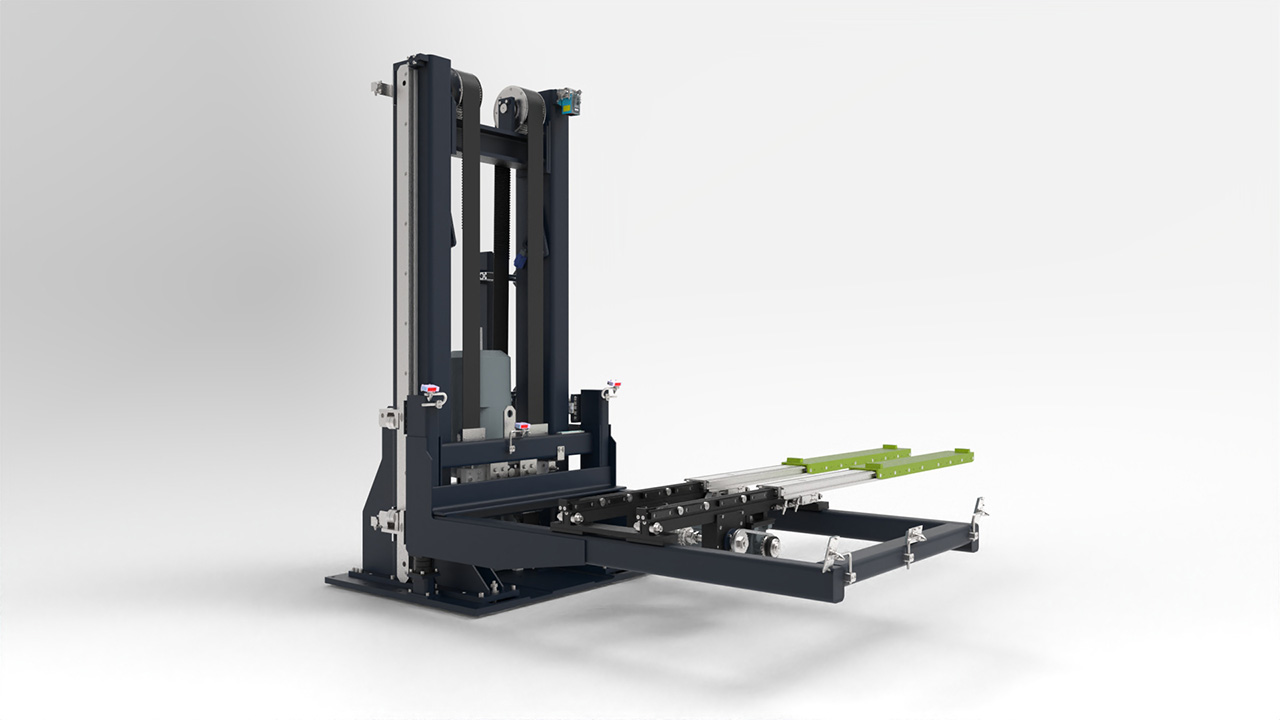

Reliable vertical conveyor with telescopic fork

Tailor-made lifting system for automotive production

We designed and manufactured a vertical conveyor with telescopic fork for the storage and retrieval of battery cells for our customer in automotive manufacturing. This device allows for reliable buffering of the cells and is designed for continuous 24-hour operation. The vertical conveyor moves the racks with the telescopic fork from the buffer storage and positions them for further processing.

Individual design for individual requirements

Taking into account the quality requirements and regulations of an automotive manufacturer, we created the design completely tailored to their needs. Thanks our extensive experience and the implementation of previous projects in the automotive industry, we were able to successfully and timely complete the entire project from planning and design to production. This also included the creation of a predictive maintenance concept in close coordination with the customer, considering ease of maintenance of the vertical conveyor with telescopic fork.

Technical data:

• Lifting height of the mast: 1620 mm

• Max. load weight: 600 kg

• Lowest discharge level: 500 mm (from the floor)

• Upper discharge level: 1900 mm (from the floor)

• Max. stroke telescopic fork: 1800 + 50 mm

• Length of the top fork: 1300 mm

• Length of telescopic fork: 1300 mm

• Speed telescopic fork (loaded / unloaded): 30 / 45 m/min