Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

OVERVIEW OF THE TELESCOPIC FORKS

5 Products

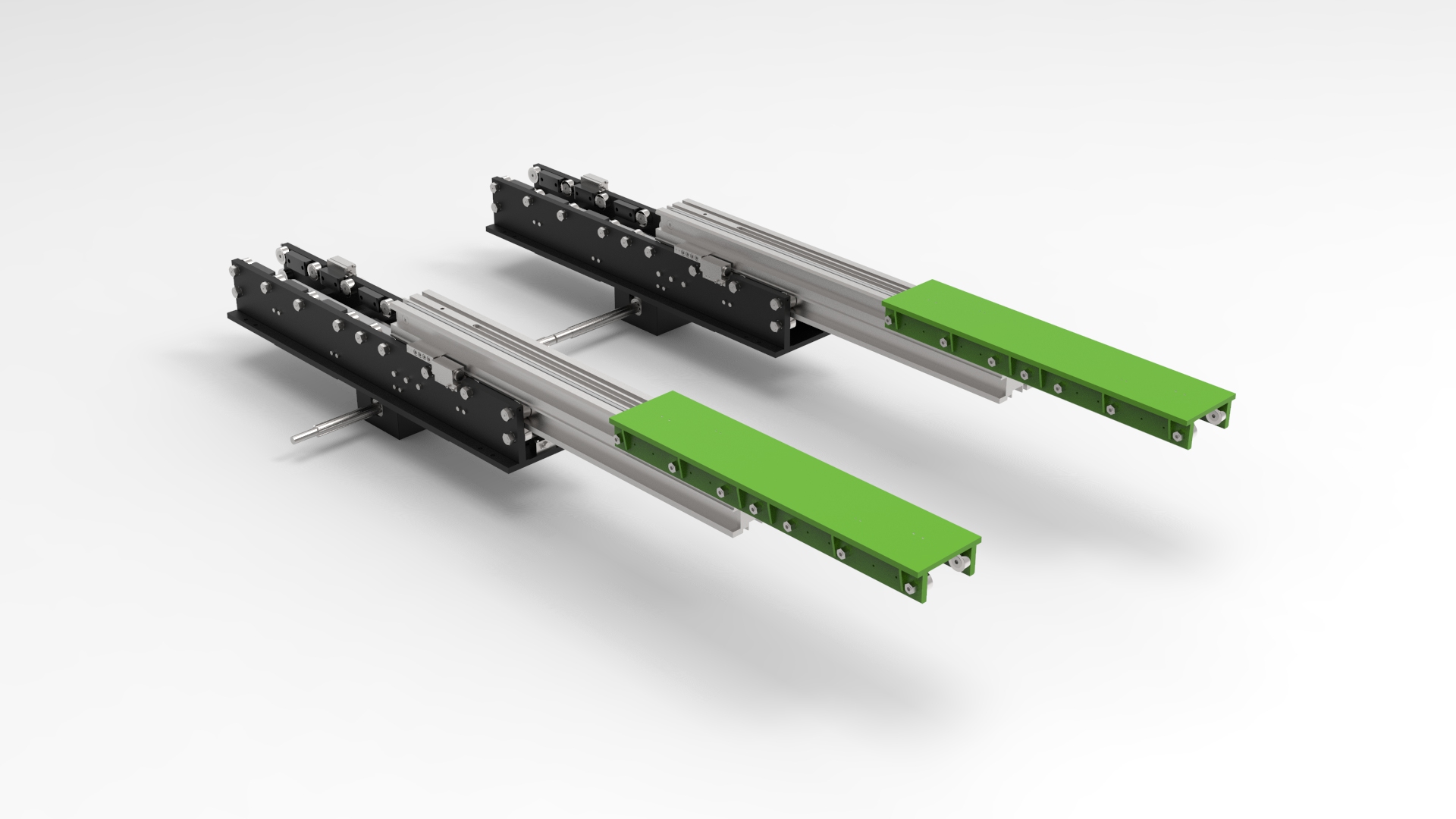

Miniload – Single and multiple deep

Our competent after-sales team will be happy to advise you at any time and will be pleased to receive your feedback on our products, order processing and our range of services.

Robust

Fast

Reliable

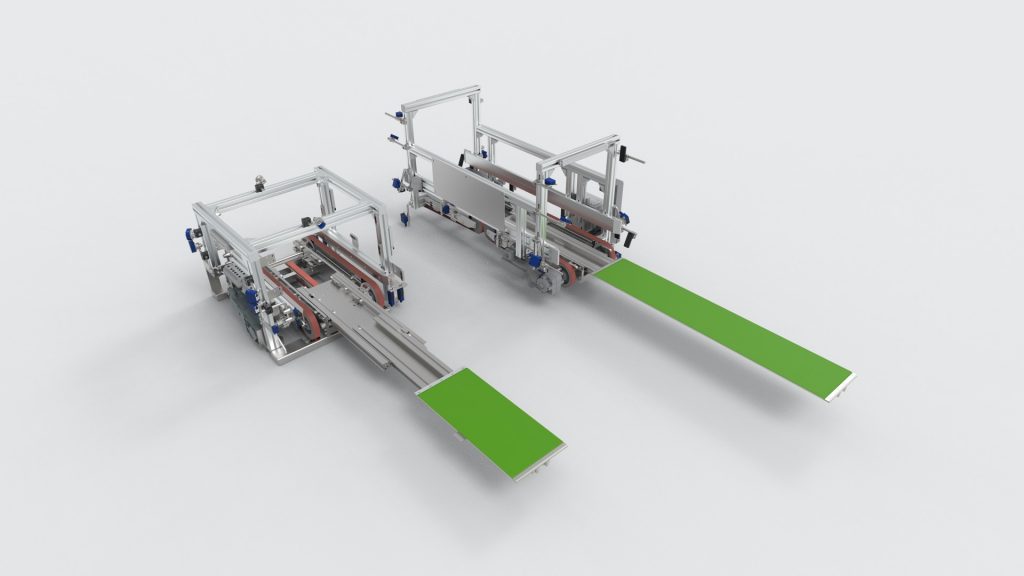

Mediload – Single deep

Our competent after-sales team will be happy to advise you at any time and will be pleased to receive your feedback on our products, order processing and our range of services.

Robust

Fast

Reliable

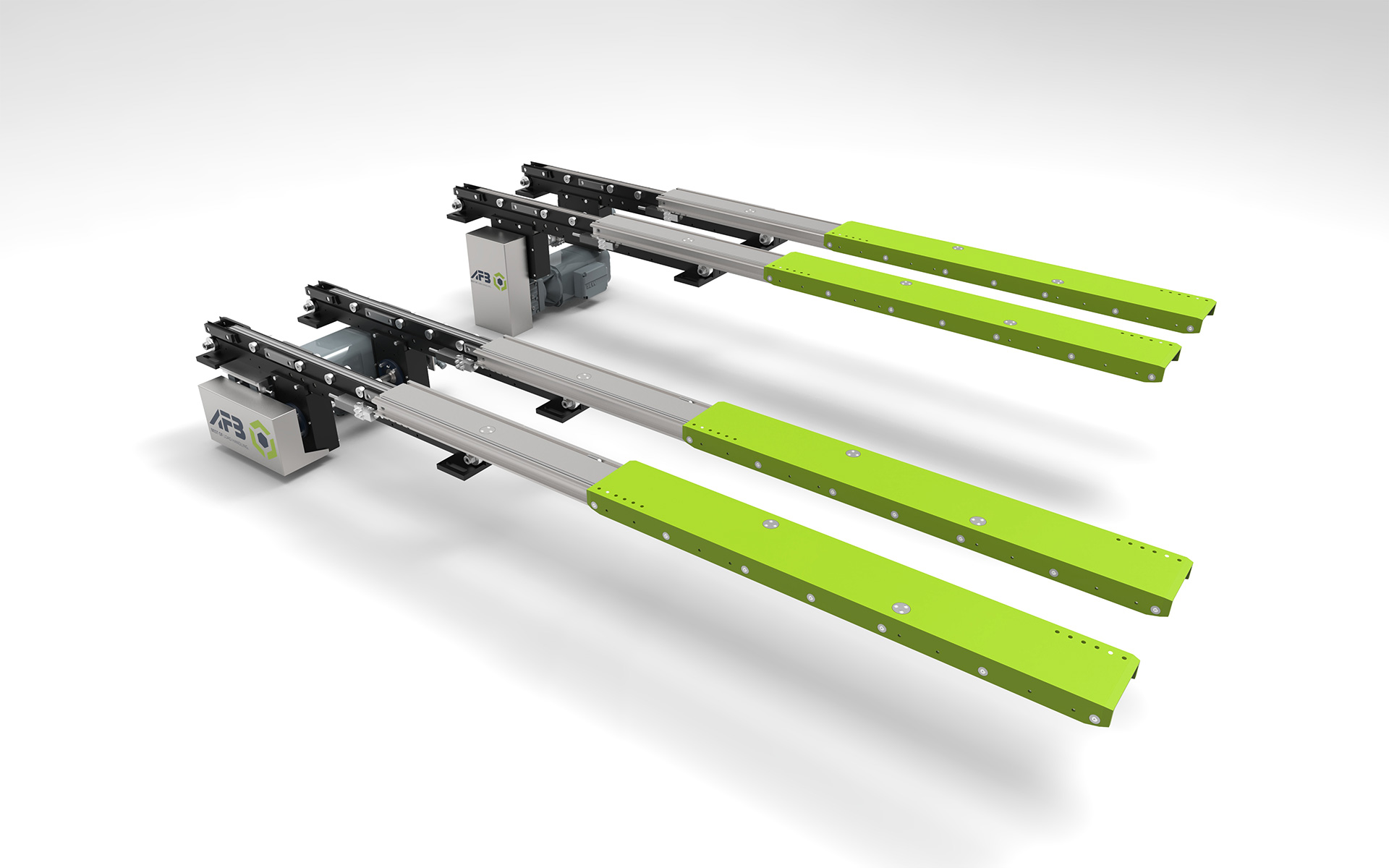

Mediload – Double and multiple deep

Our competent after-sales team will be happy to advise you at any time and will be pleased to receive your feedback on our products, order processing and our range of services.

Robust

Fast

Reliable

Mediload – Vario S

Our competent after-sales team will be happy to advise you at any time and will be pleased to receive your feedback on our products, order processing and our range of services.

Robust

Fast

Reliable