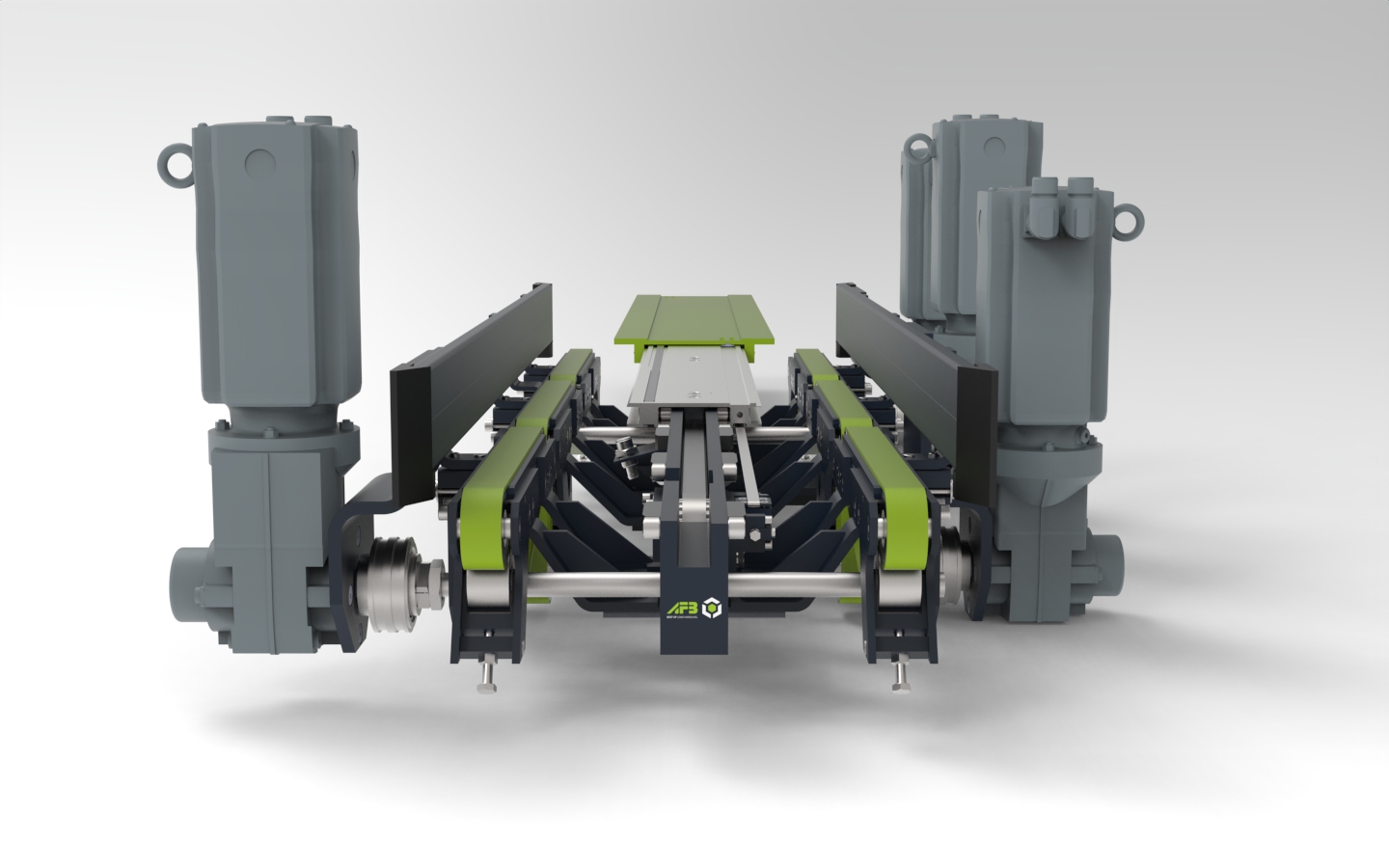

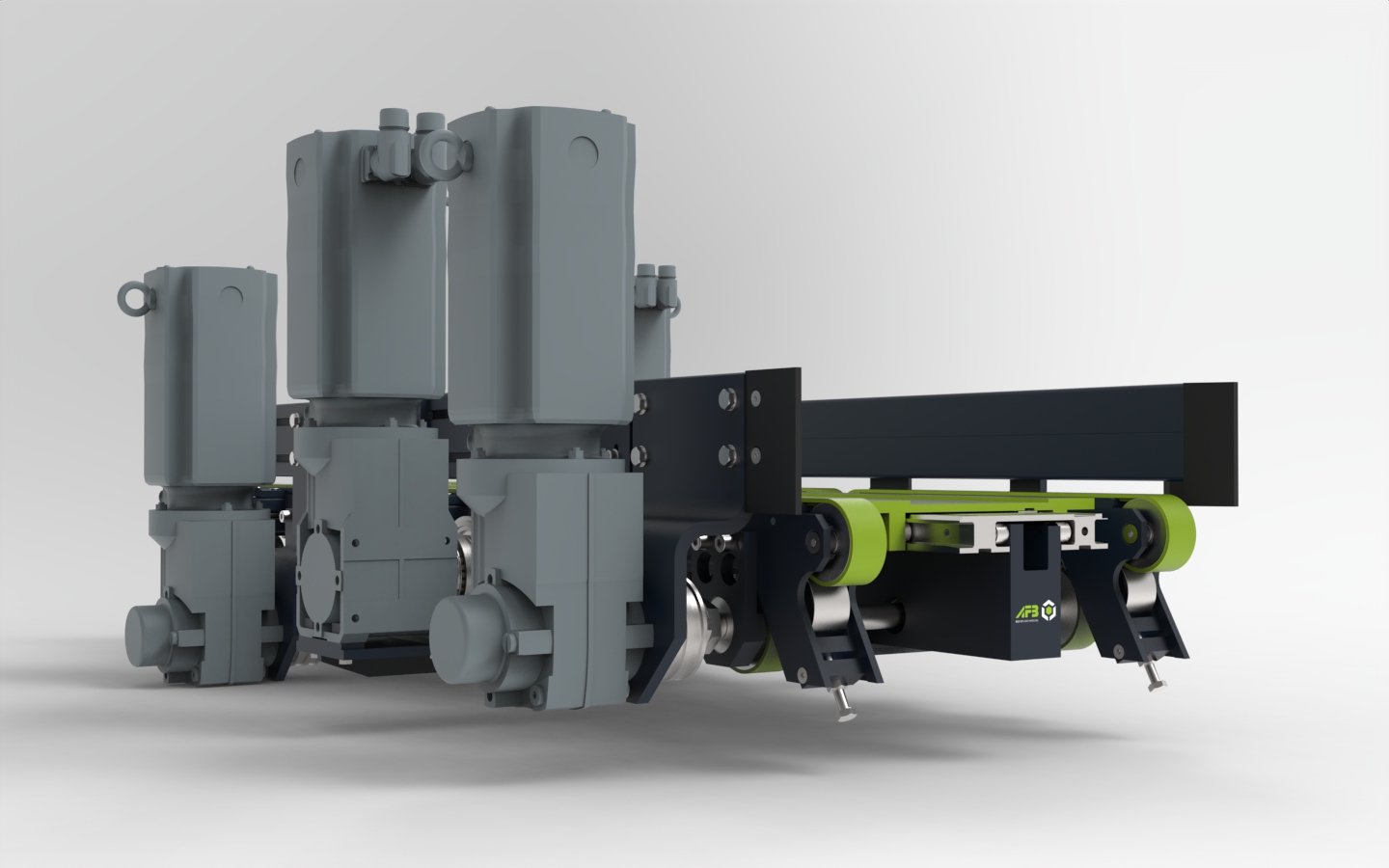

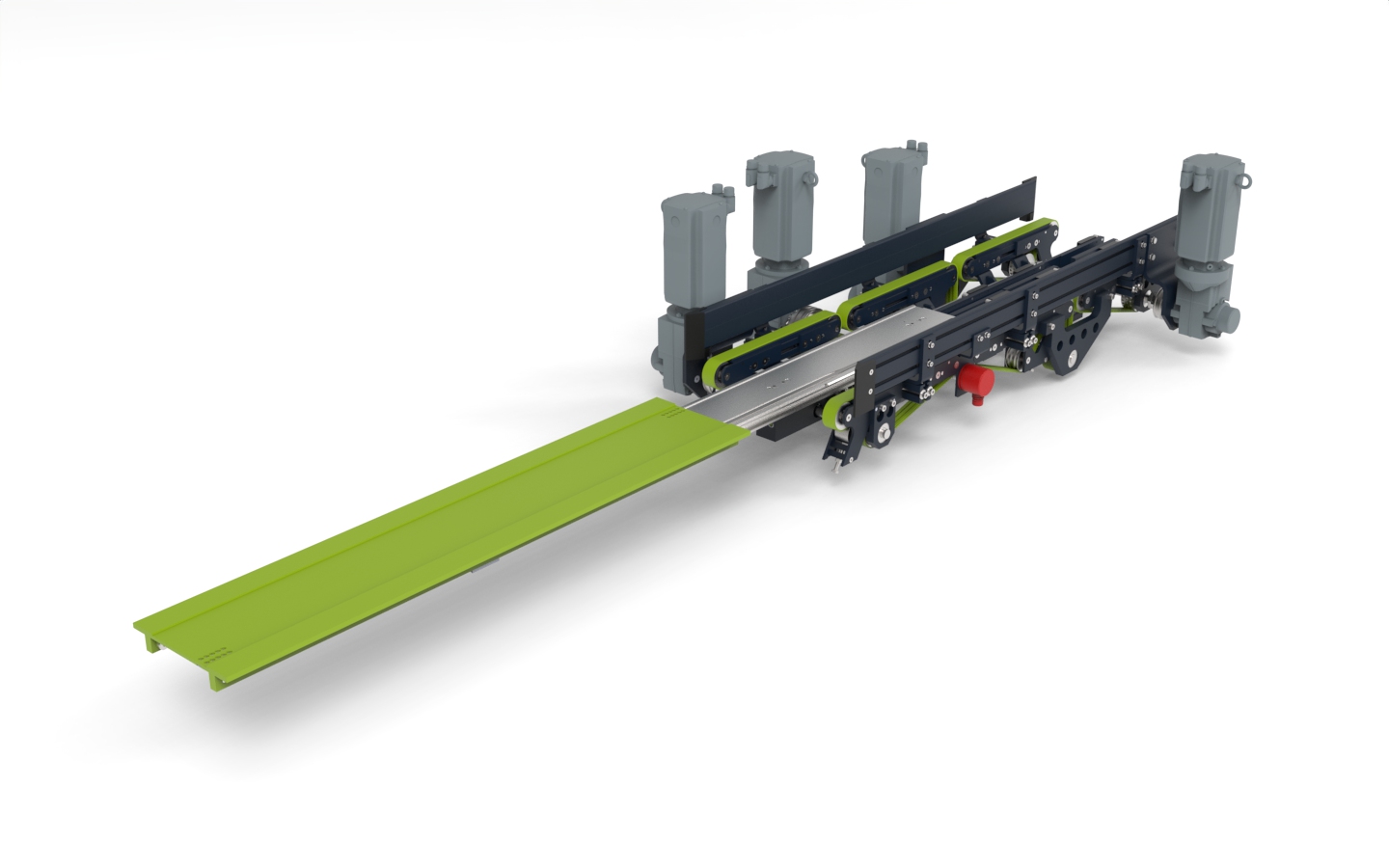

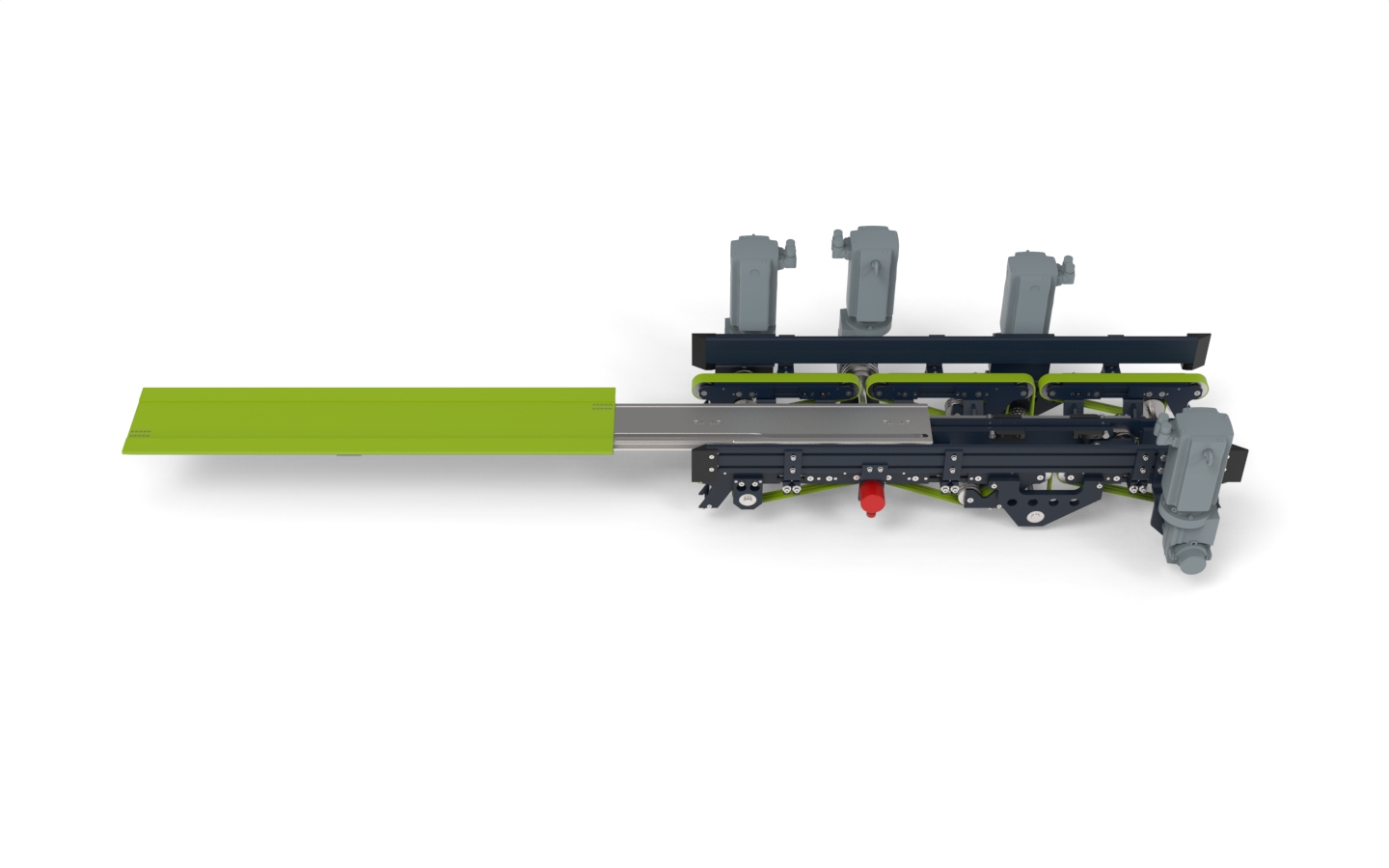

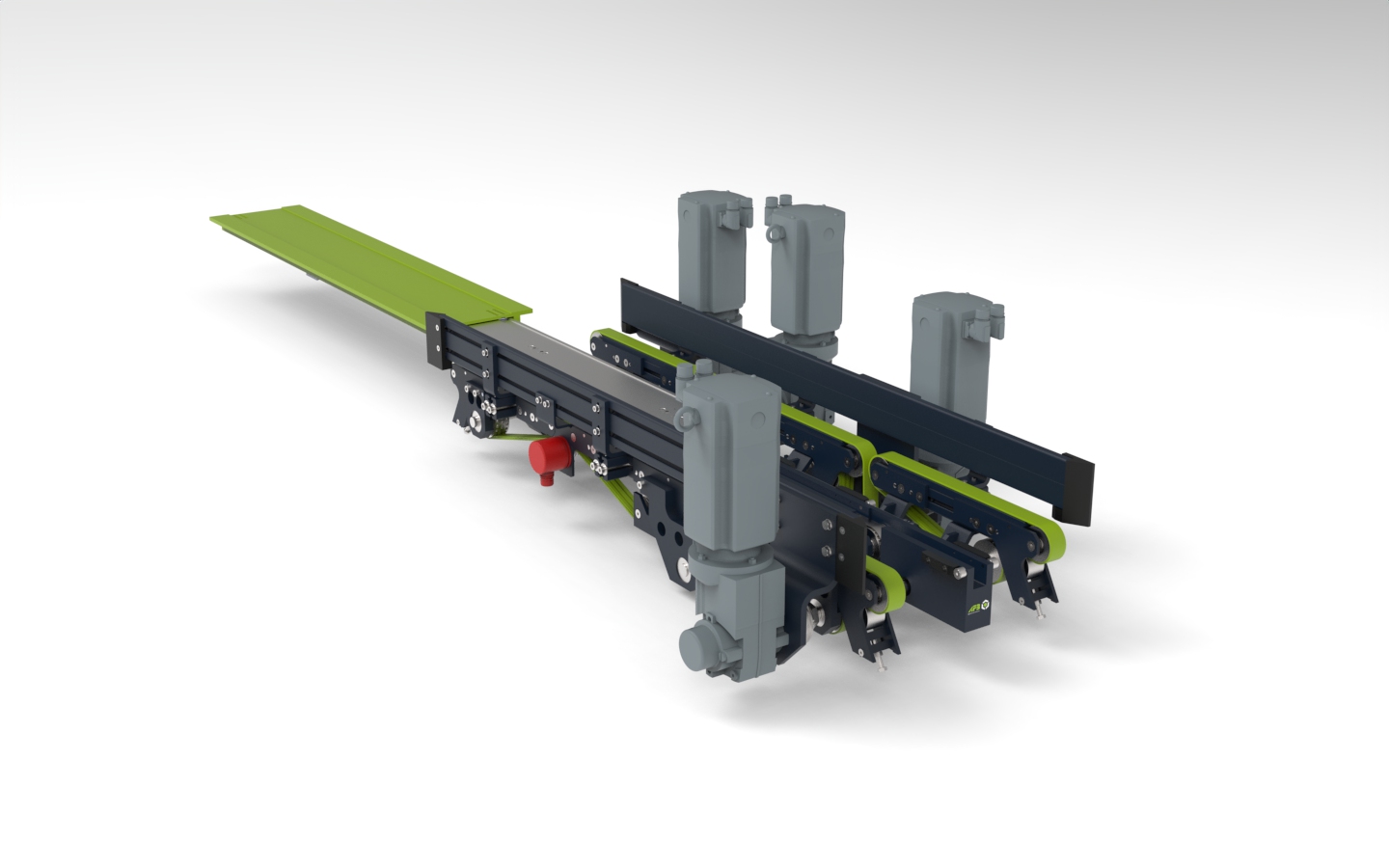

Compact Telescopic Fork Solution for Modern Small Parts Warehouse Applications

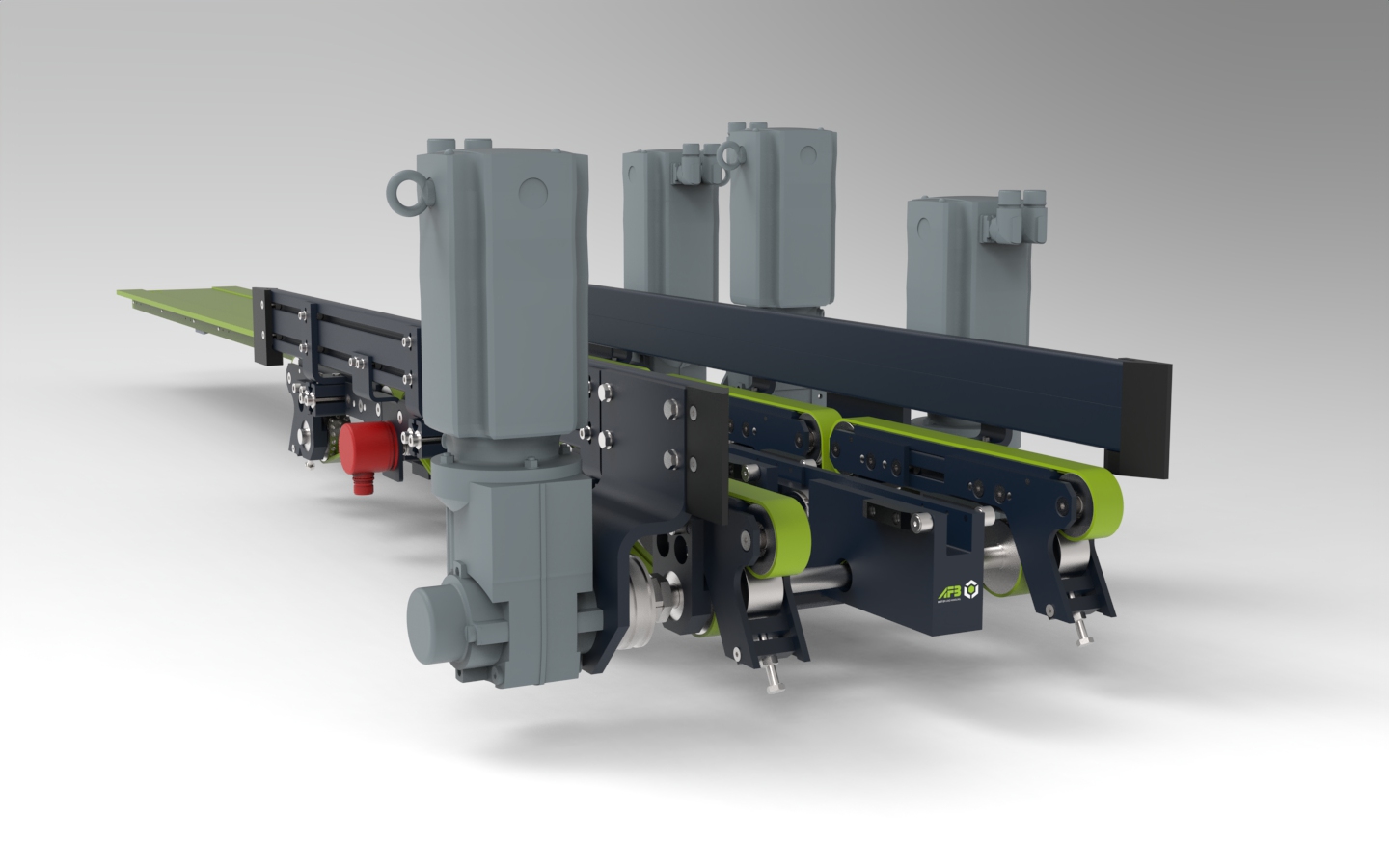

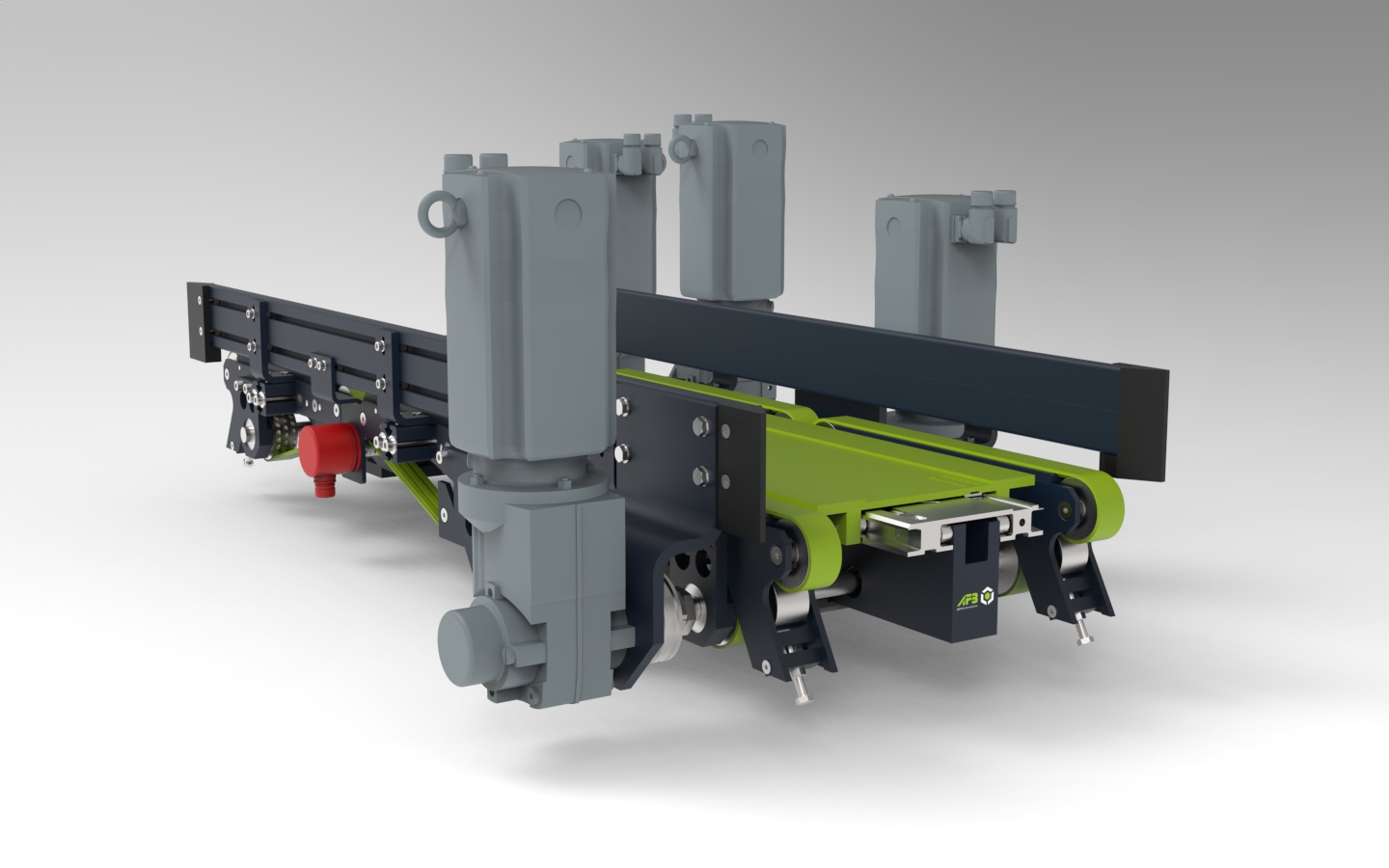

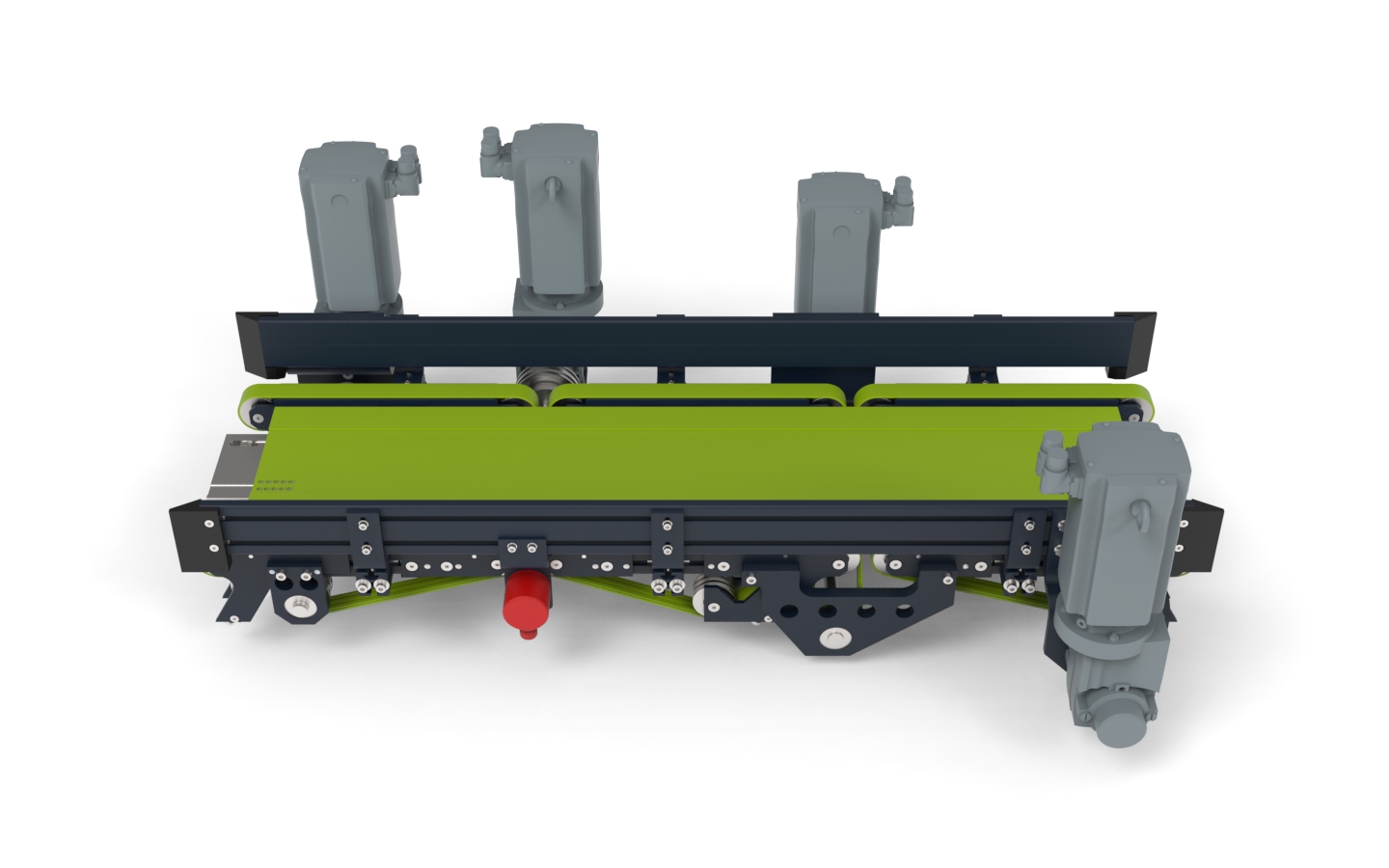

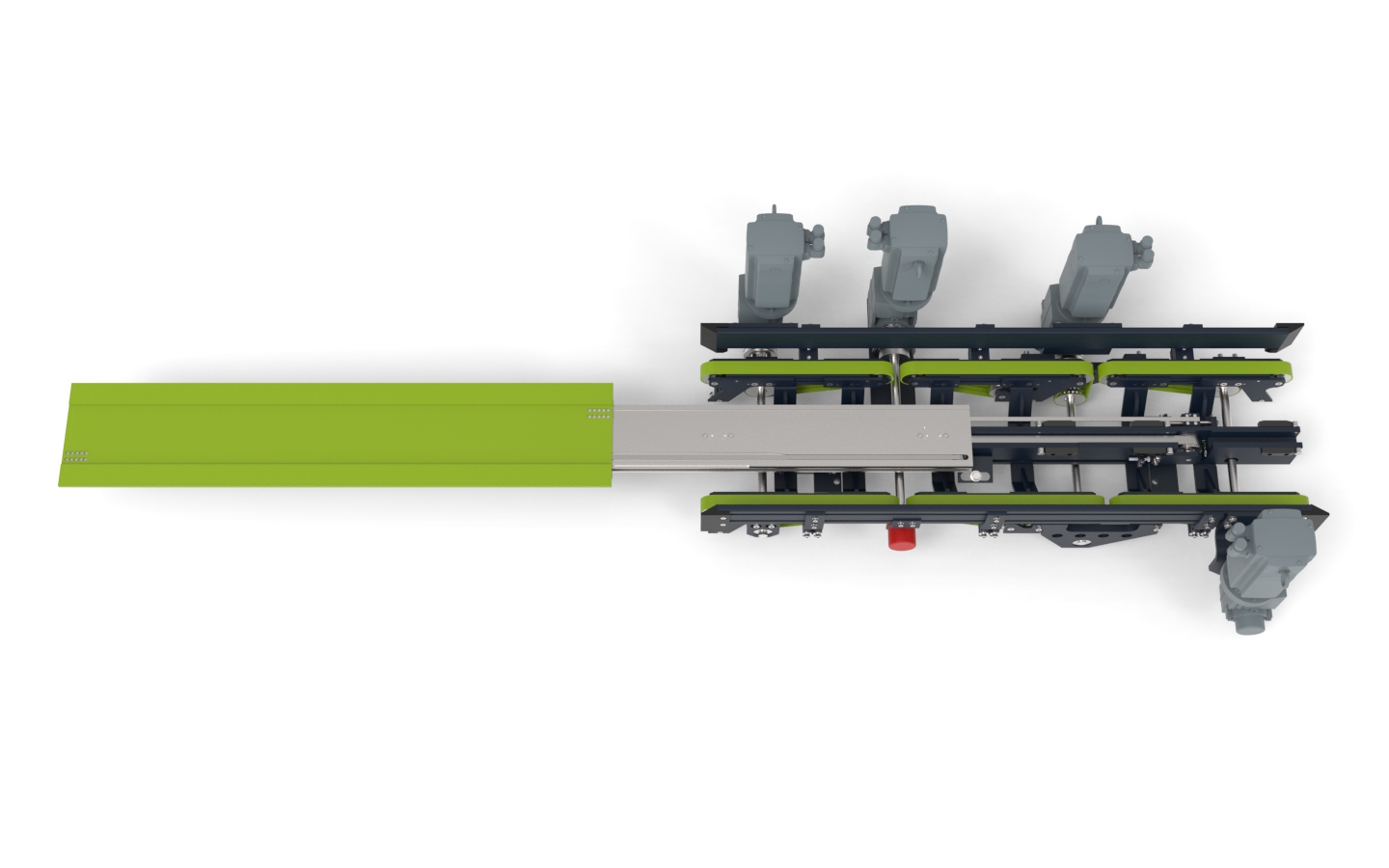

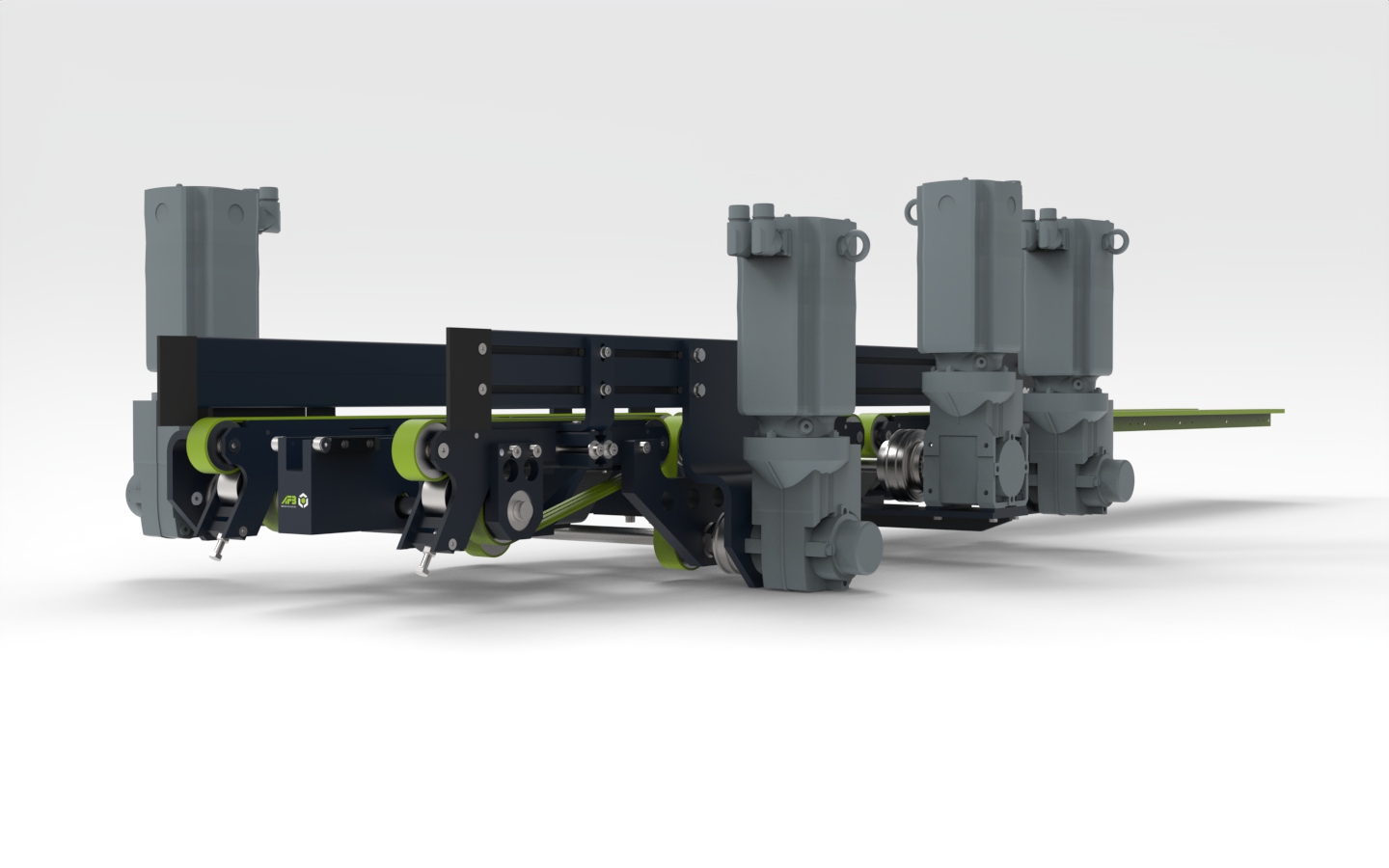

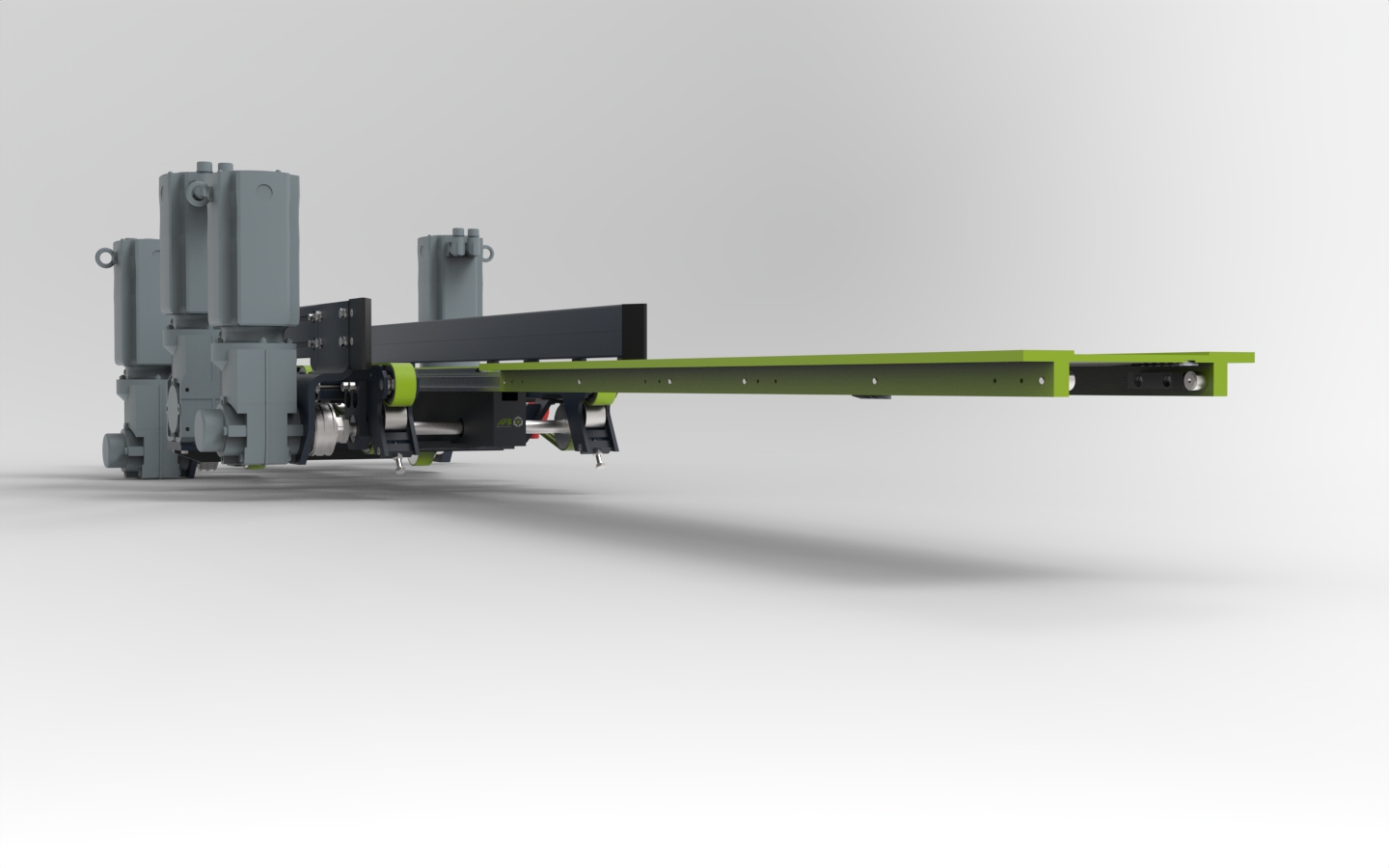

Our R32ST-180/240-N-1300 telescopic fork unit is specially designed for use in automated small parts warehouses. It combines a particularly flat and compact design with an integrated box guide. This design enables optimal use of the storage and retrieval machine’s installation space while ensuring the boxes are handled safely and efficiently. With a load capacity of 90 kg, this version of the telescopic fork unit can reliably meet the requirements of dynamic material flow processes.

Flexible Order Picking Thanks to Triple Pick-Up

The load handling device enables either simultaneous loading of three containers or sequential picking within the same storage aisle. Three integrated belt conveyors transfer containers from the storage and retrieval machine to the conveyor system below for order picking, for example in the direction of order picking, or take the containers from the conveyor system. If the triple pick-up is not operating at full capacity, containers in the aisle can be picked up sequentially, ensuring a seamless material flow without the need for additional interfaces.

Higher Performance Through Efficient Buffering

The ability to temporarily store multiple containers directly on the telescopic fork unit reduces the number of cycles required per container significantly. This improves the overall performance of the automated small parts warehouse while also reducing the stacker crane’s operational time in the transfer area. Tailored precisely to the customer’s requirements for 24/7 continuous operation, the system meets AFB’s high quality standards.

Would you like to improve the efficiency of your intralogistics?

Get in touch with our sales team, who will be happy to advise you on customised solutions for your material flow.

Technical data:

-

Payload: 90 kg

-

Stroke: 1,400 + 25 mm

-

Length of the top fork: 1,180 mm

-

Length of the unit: 1,300 mm

-

Speed (loaded / unloaded): 50 / 80 m/min

-

Acceleration (loaded / unloaded): 8 / 2 m/s2

-

Self weight of the complete unit: approx. 200 kg