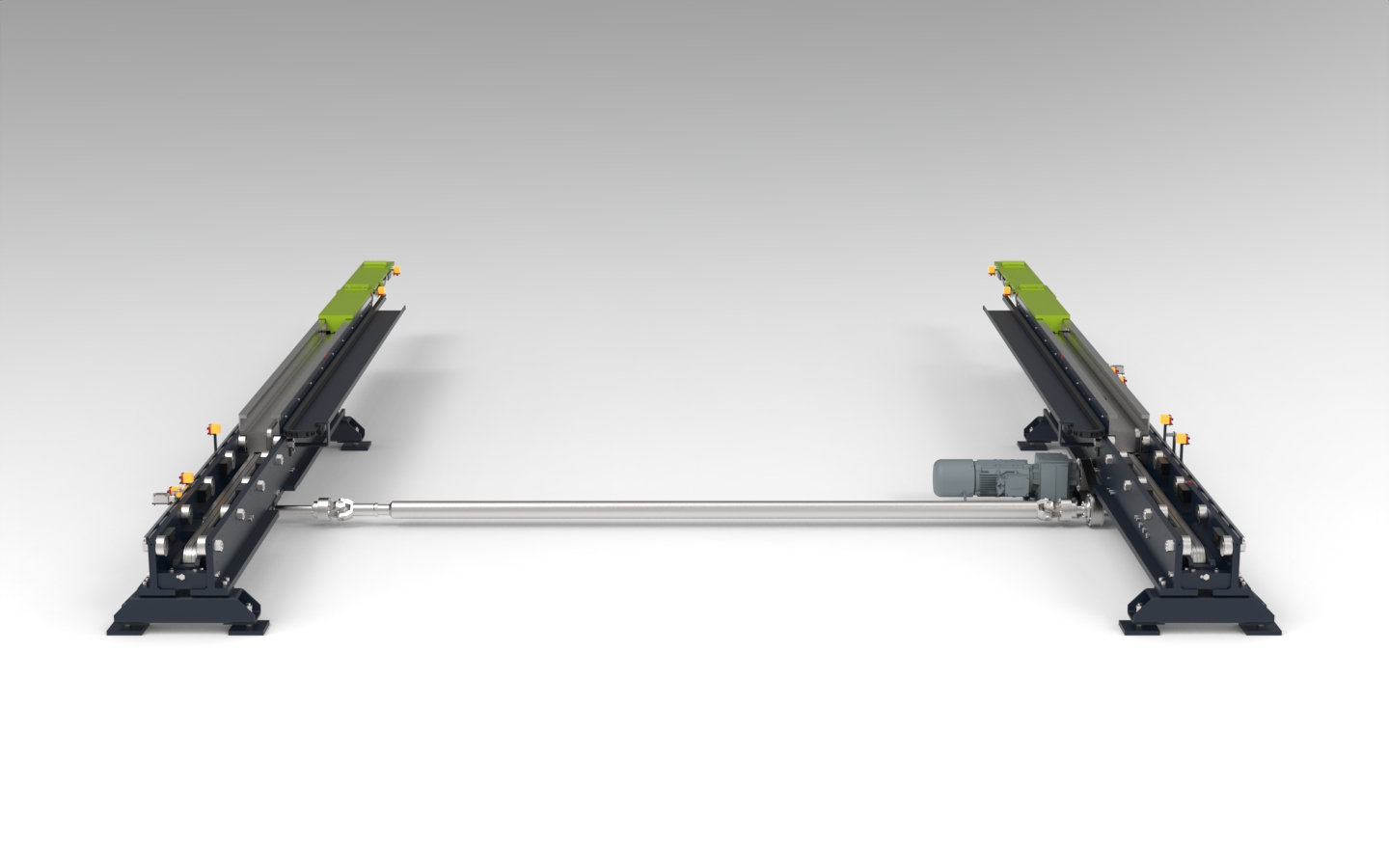

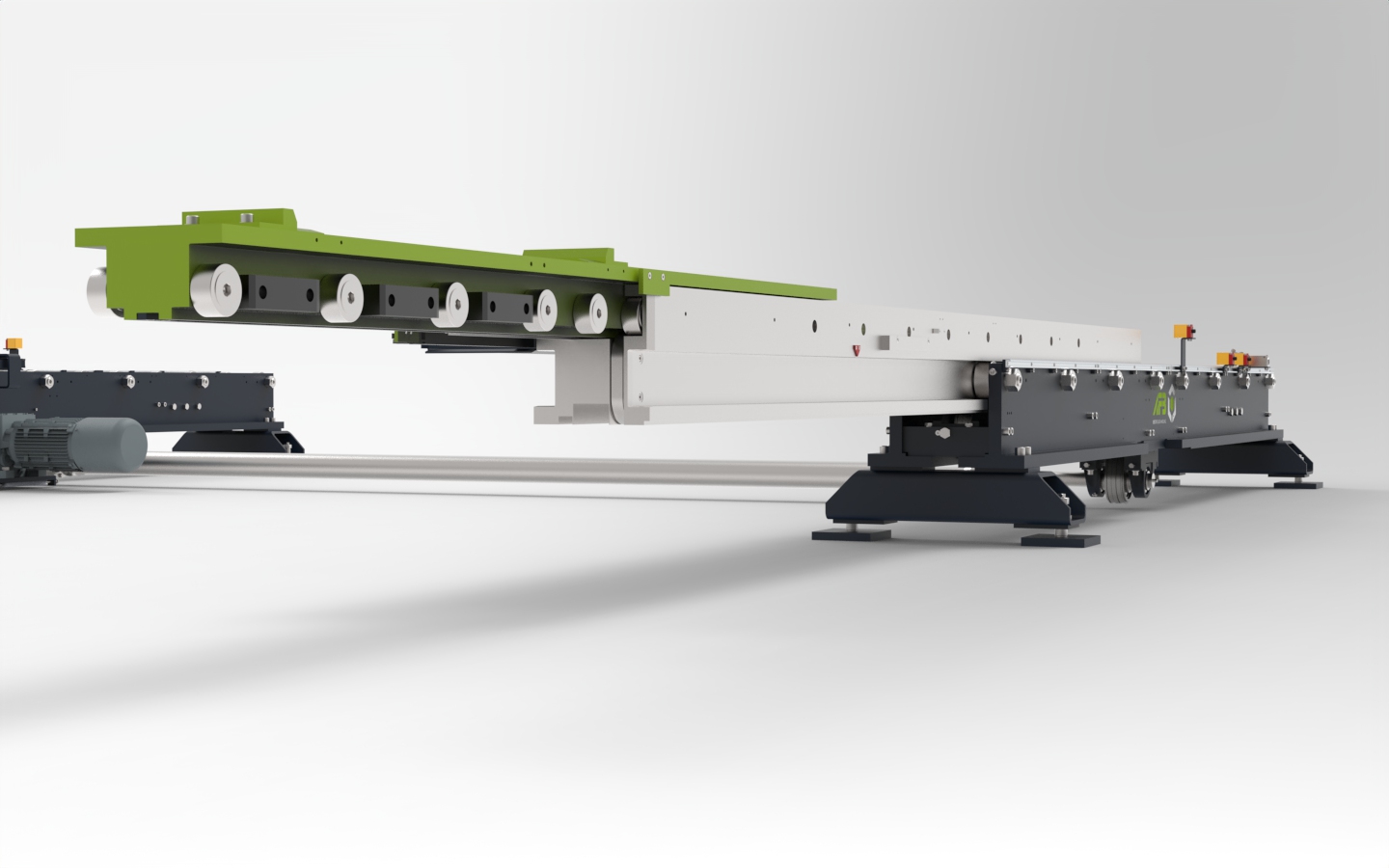

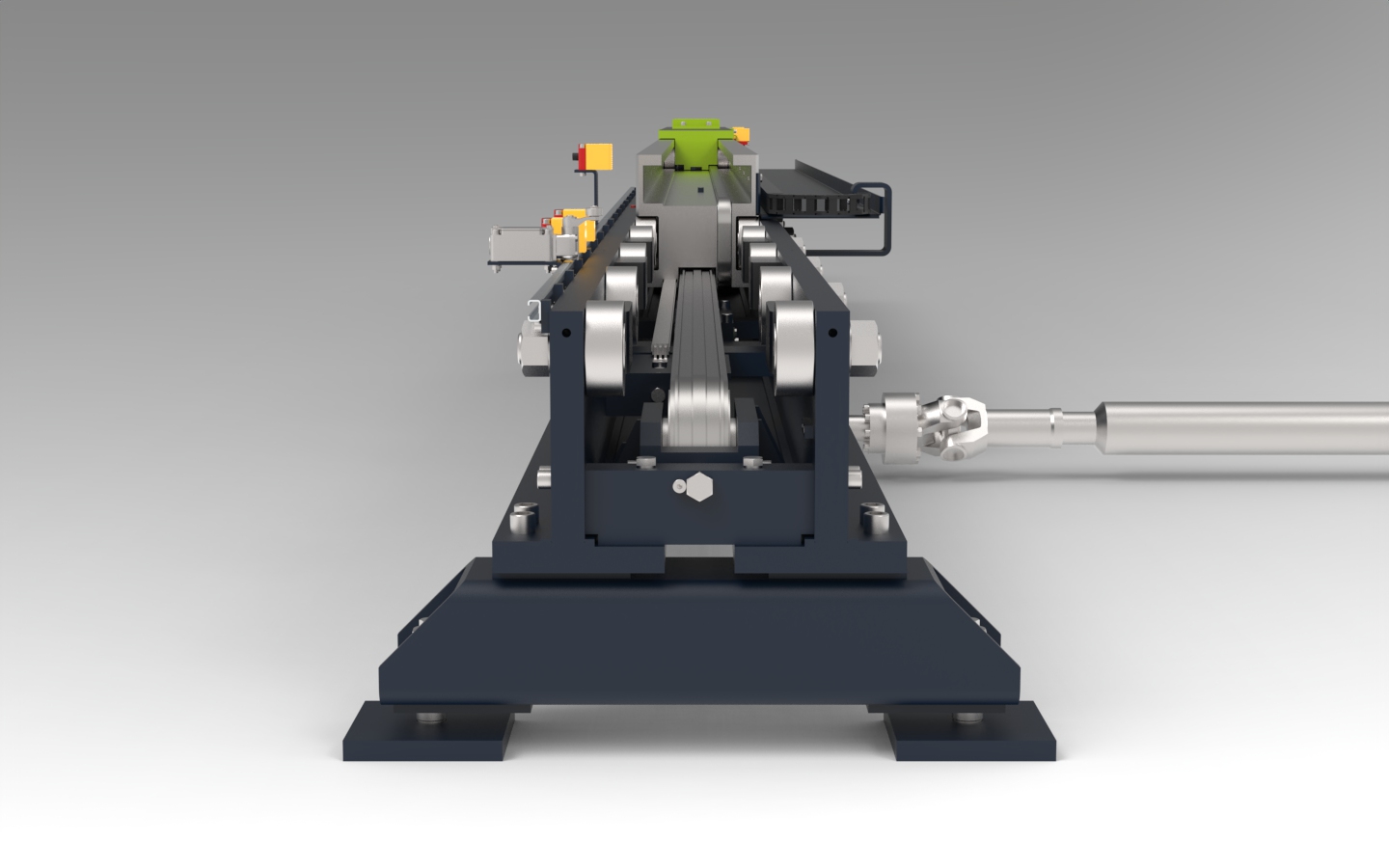

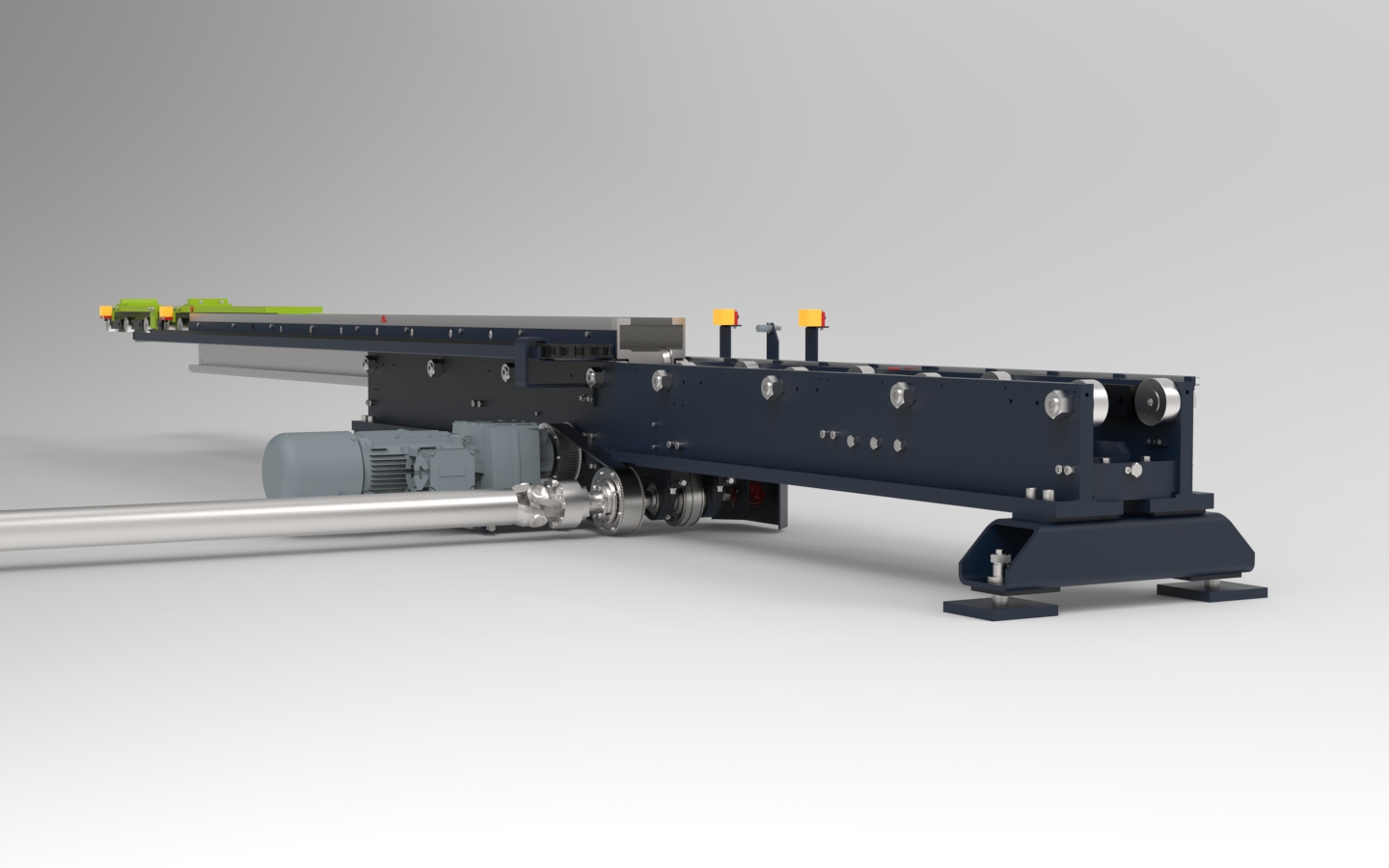

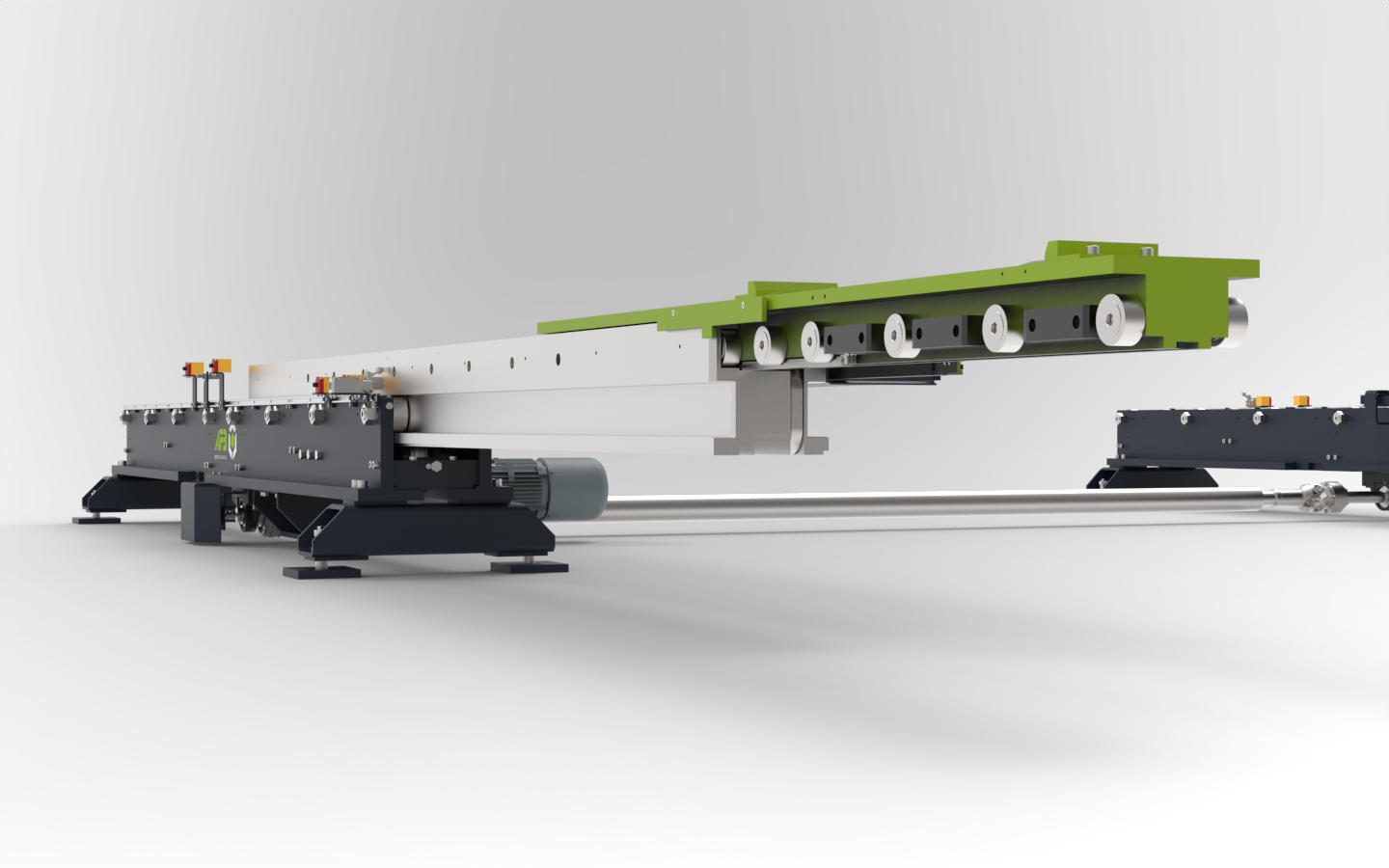

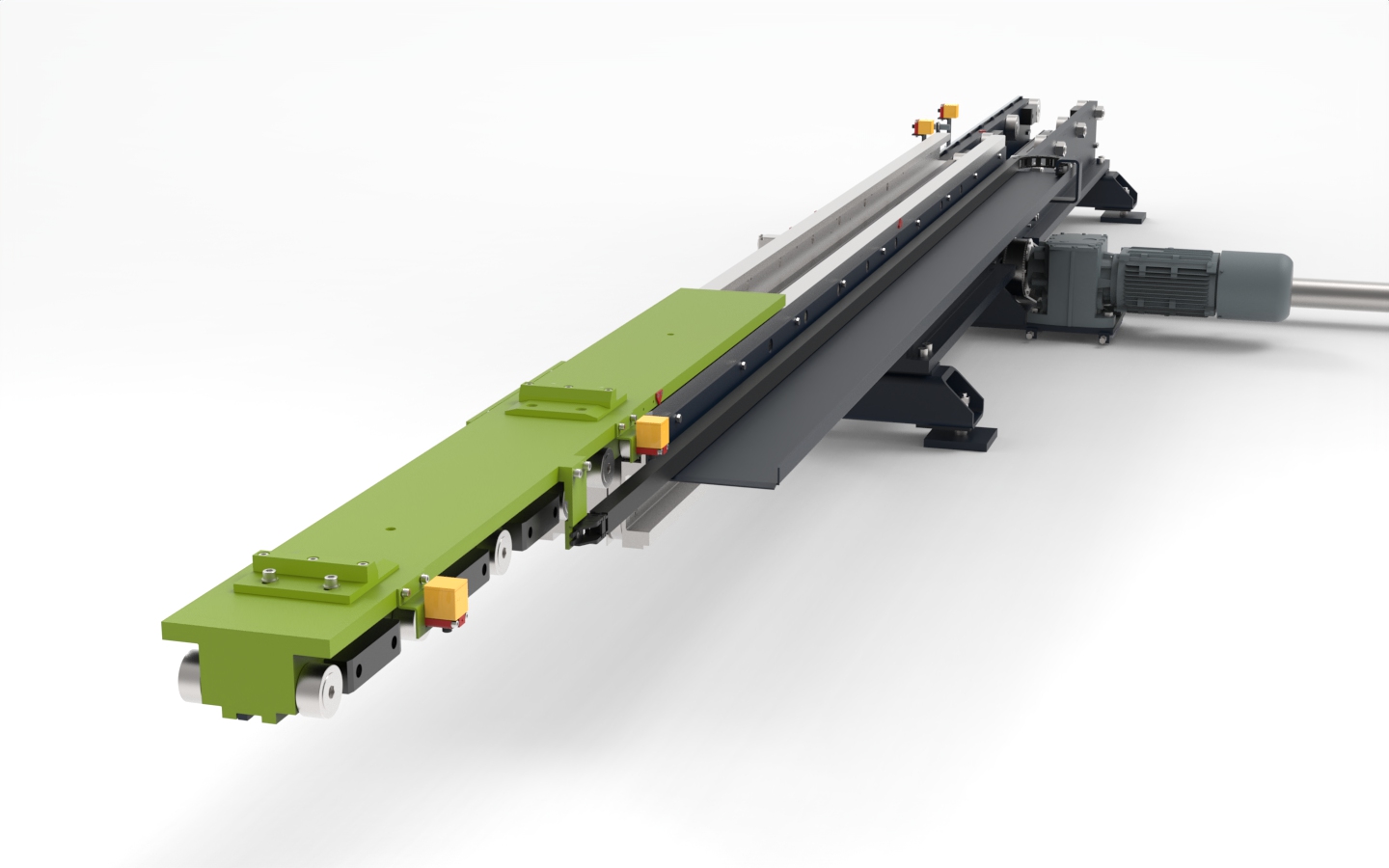

Efficient Handover Processes with the Telescopic Fork 250-210-VK-3400

The telescopic forks unit are installed on a robust, stationary frame that takes load carriers from a vertical conveyor. Afterwards the telescopic fork unit transfers the load carriers in a controlled process to a stationary unit. From there, the load carriers are transported further or they are subsequently processed. With a stroke of 3,500 mm, the system covers a large working area. Due to the proven AFB quality, the system is designed for continuous, 24/7 industrial use — it is low-maintenance, precise, and durable.

Customization and Smart Sensor Technology

To ensure optimal integration into the existing production environment, the telescopic fork unit was fitted with a specially adapted top fork. It was prepared for the installation of individual mounts for customer-specific load carriers. Additionally, integrated position detection sensors for the skids ensure maximum process reliability and a smooth transfer between system components.

Contact Our Sales Team

Would you like to learn more about using telescopic forks in your production process, or would you like to develop a custom solution for your application?

👉 Contact our sales team—we will be happy to advise you personally.

Technical data:

-

Load: 2400 kg

-

Stroke: 3500 + 200 mm

-

Length of the top fork: 2000 mm

-

Length of the unit: 3400 mm

-

Speed (loaded / unloaded): 30 / 60 m/min

-

Acceleration (loaded / unloaded): 0,5 / 1 m/s2

-

Self weight of the complete unit: approx. 1620 kg