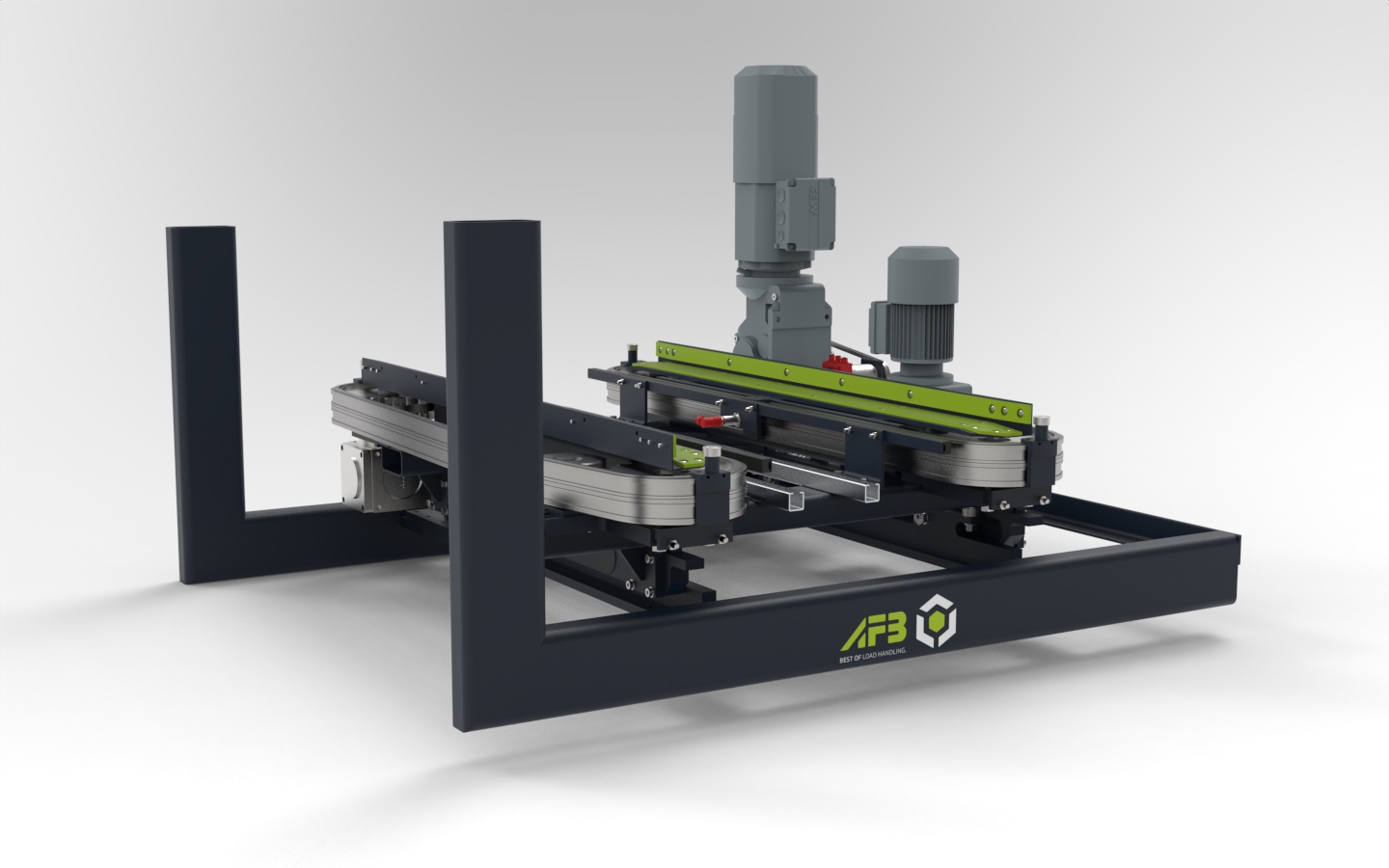

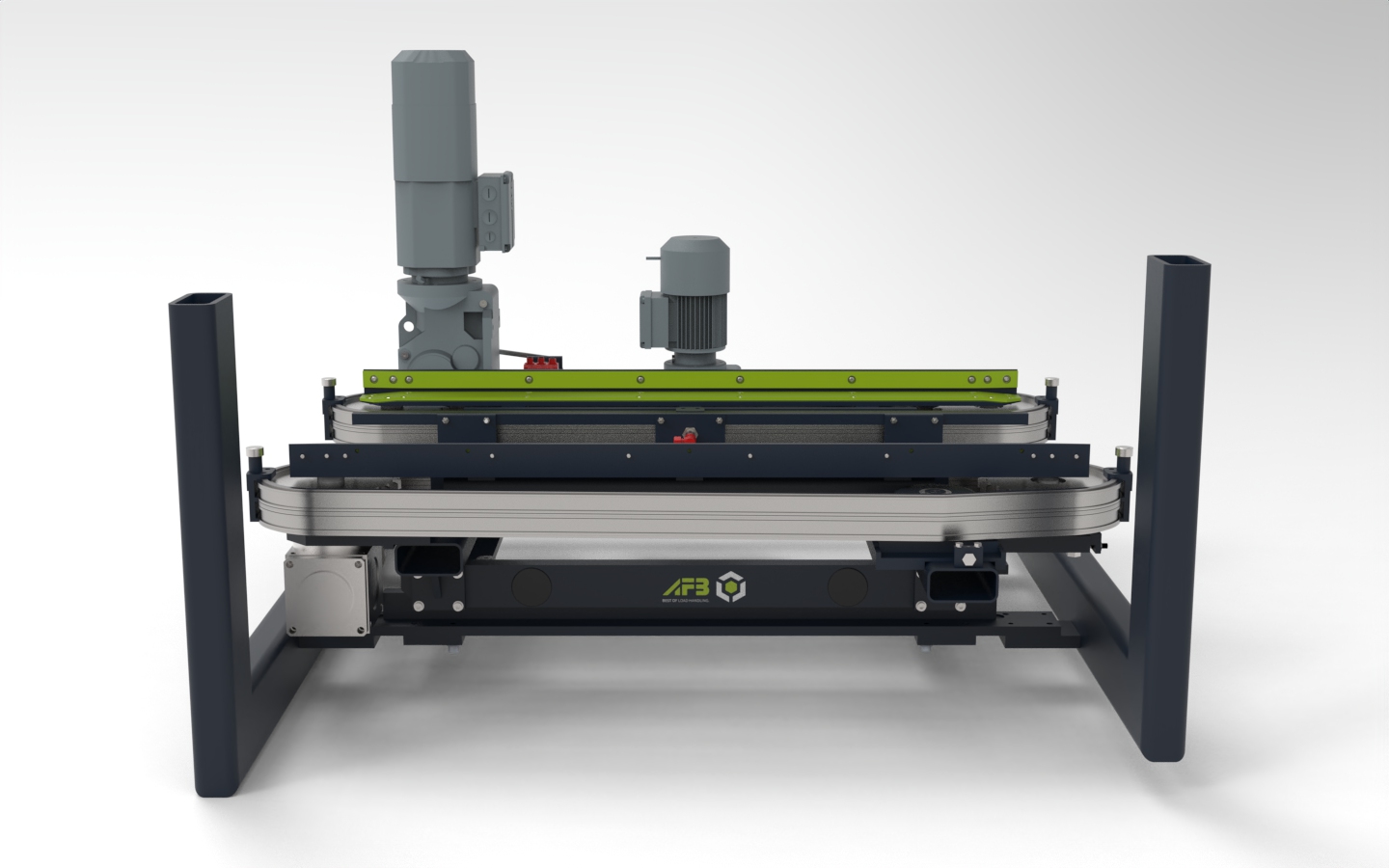

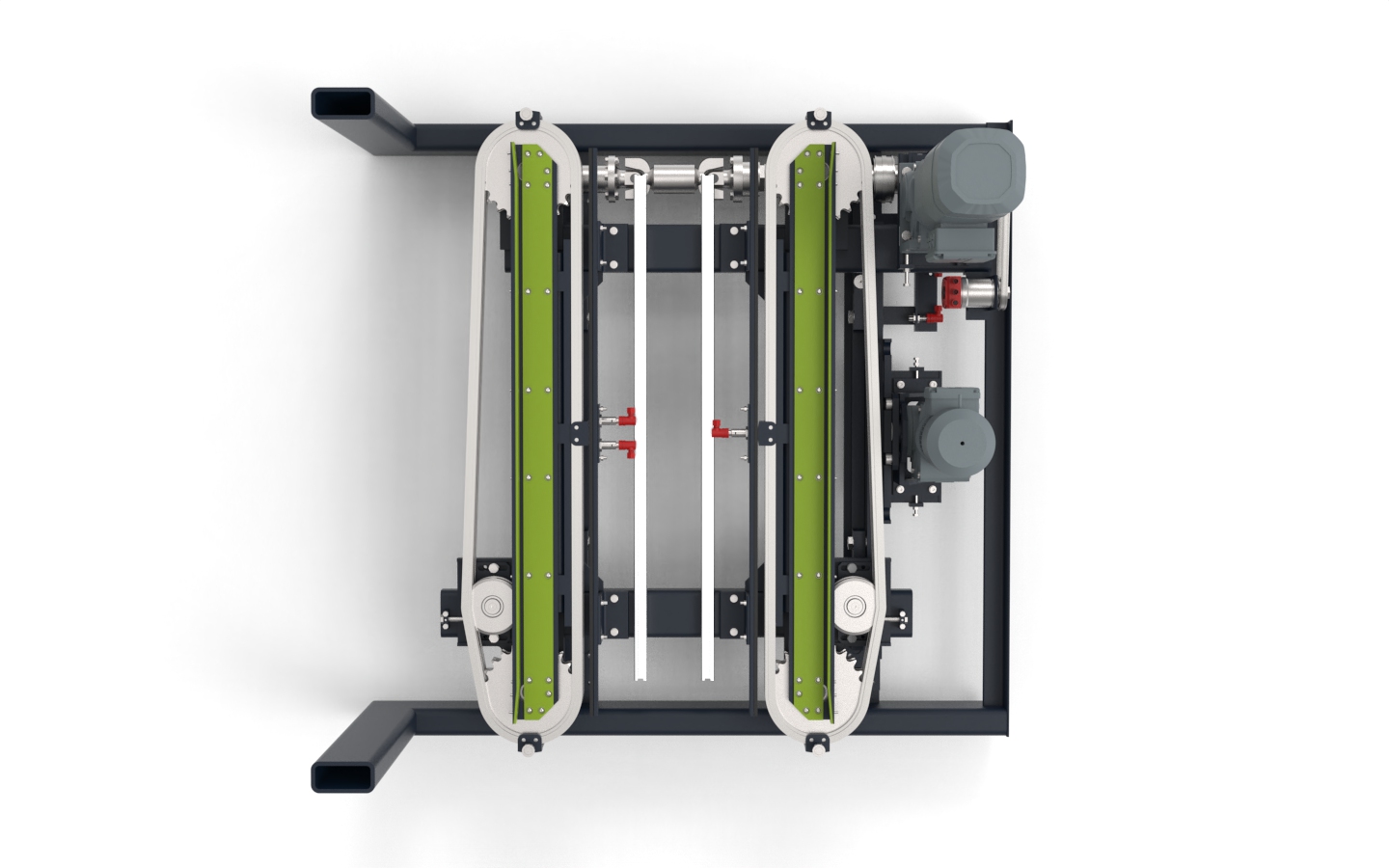

Efficient Modernization with the 300-1300 Push-Pull System

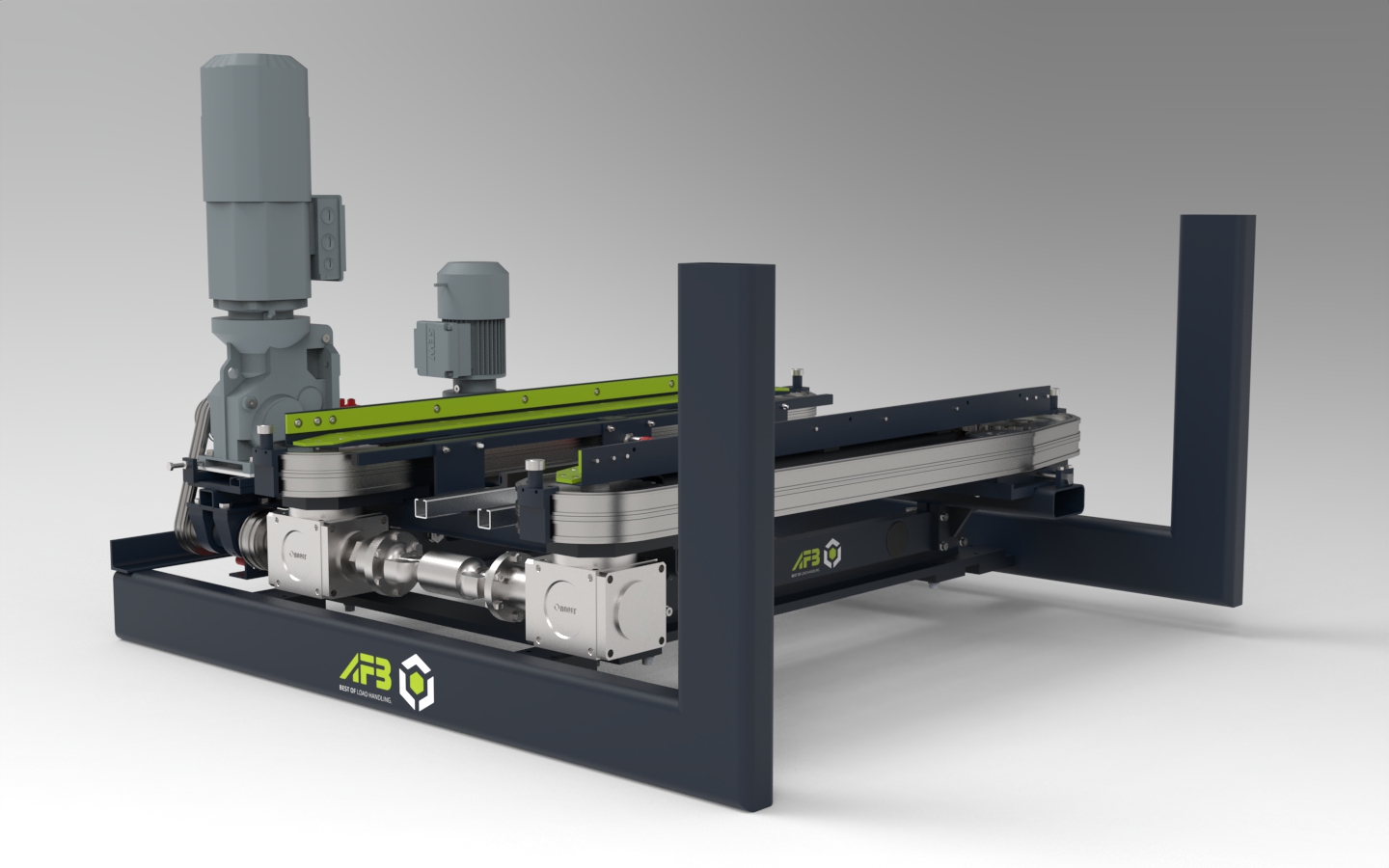

We designed our special 300-1300 push-pull system for the modernization of an existing automated small parts warehouse (AKL). The main task in this retrofit project was to retain existing structures while significantly increasing the warehouse’s performance.

Optimized storage and retrieval of trays

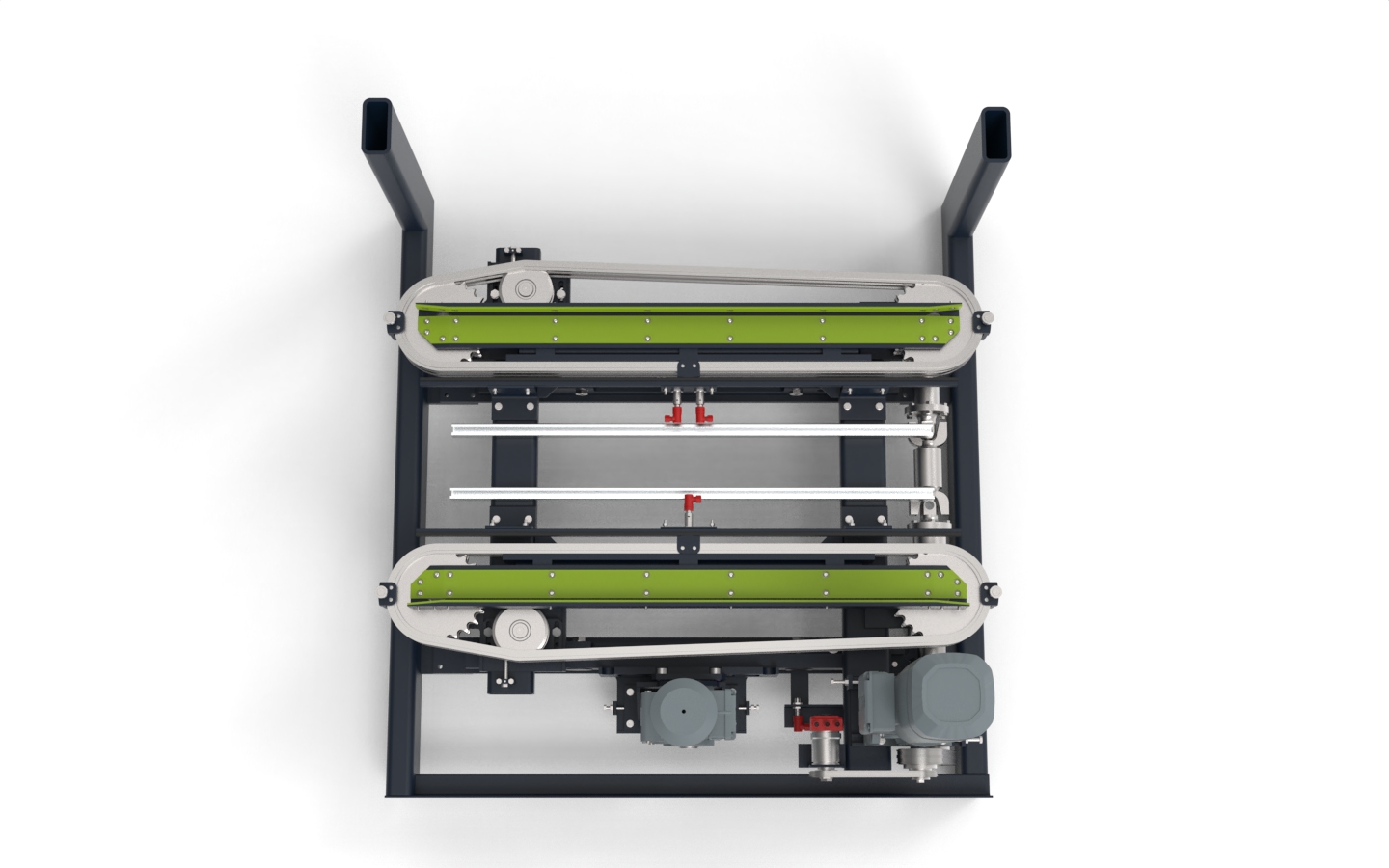

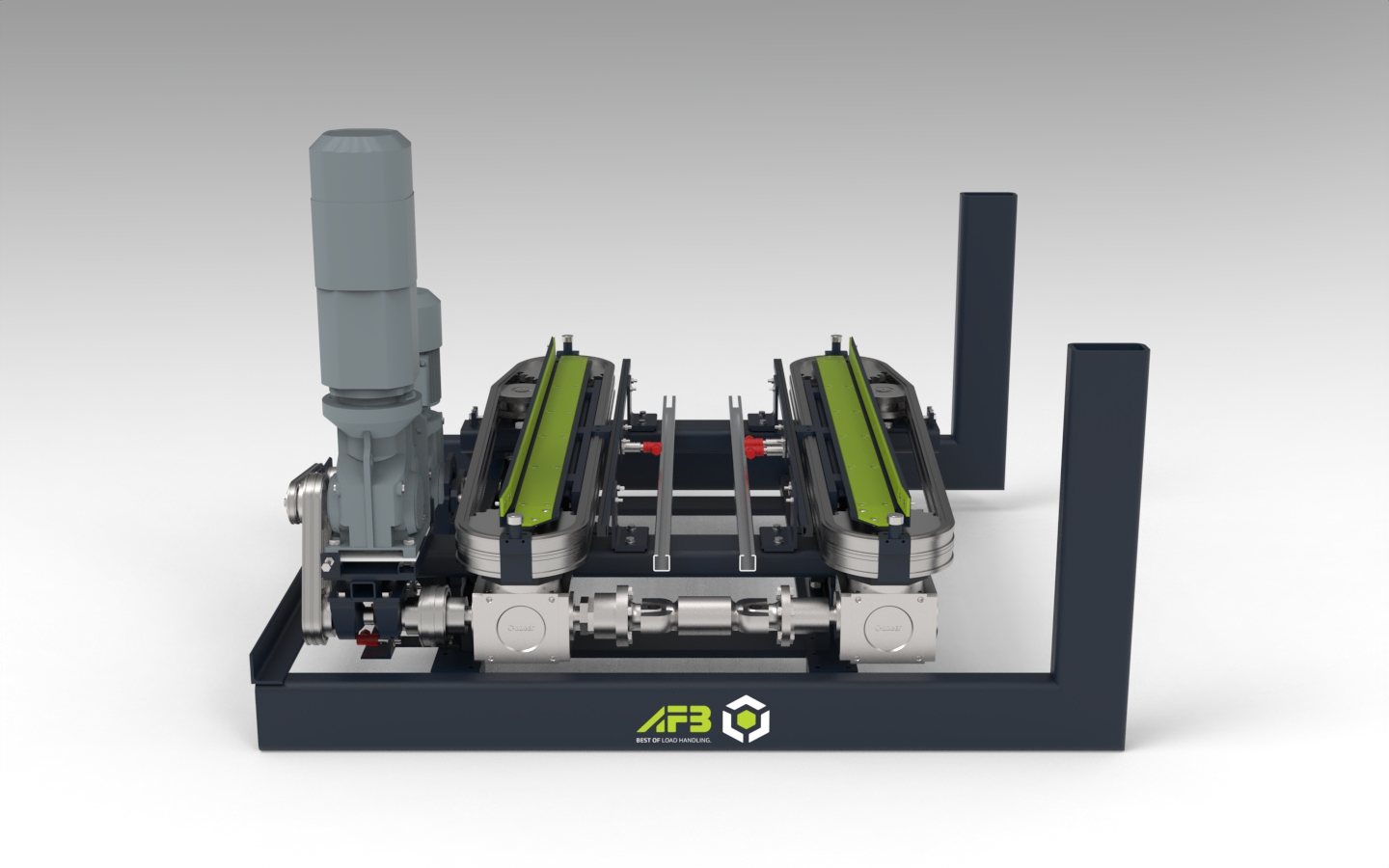

The push-pull system automatically stores and retrieves trays with the dimensions 1320 x 620 mm. Up to three boxes can be placed in a row on each tray. The precise and reliable technology ensures a continuous flow of materials, significantly increasing throughput. At the same time, the system increases the overall availability of the warehouse.

Quality and Integration for Continuous Operation

A key challenge was the seamless integration of the push-pull system into the existing warehouse. Due to the customisation and proven quality of AFB, a solution was created that meets both the high demands of 24/7 operation and the individual conditions on site. Our push-pull system 300-1300 therefore provides a future-proof solution for modernized intralogistics systems.

Would you like to learn more about our solutions for modernizing existing plants? Contact our sales team—we will be happy to advise you personally.

Technical Data:

-

Load carrier: metal tray

-

Load weight: 300 kg

-

Relative stroke: 280 mm

-

Length of the unit: 1300 mm

-

Speed: 60 m/min

-

Acceleration: 0,8 m/s2

-

Self weight of the complete unit: approx. 350 kg