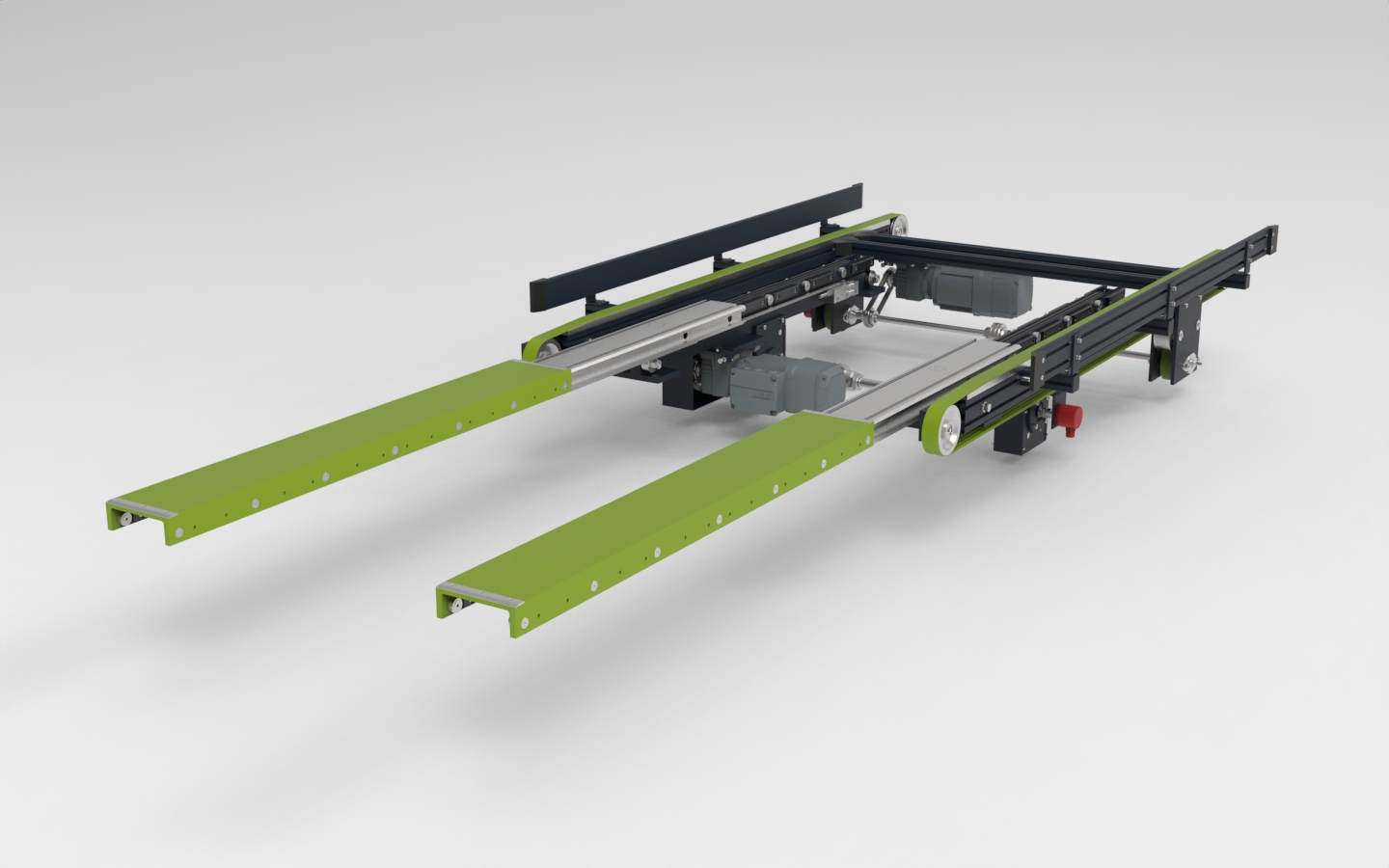

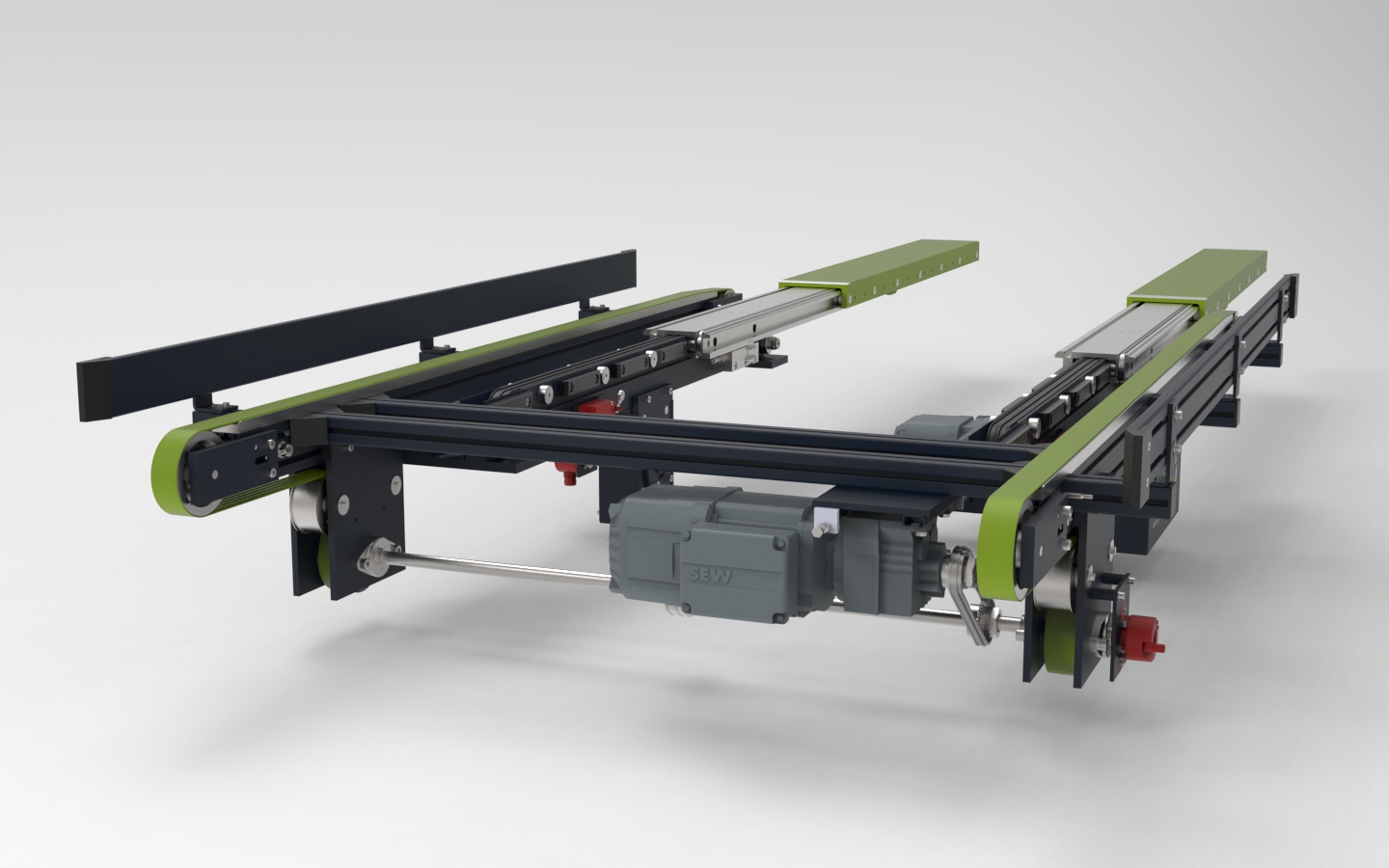

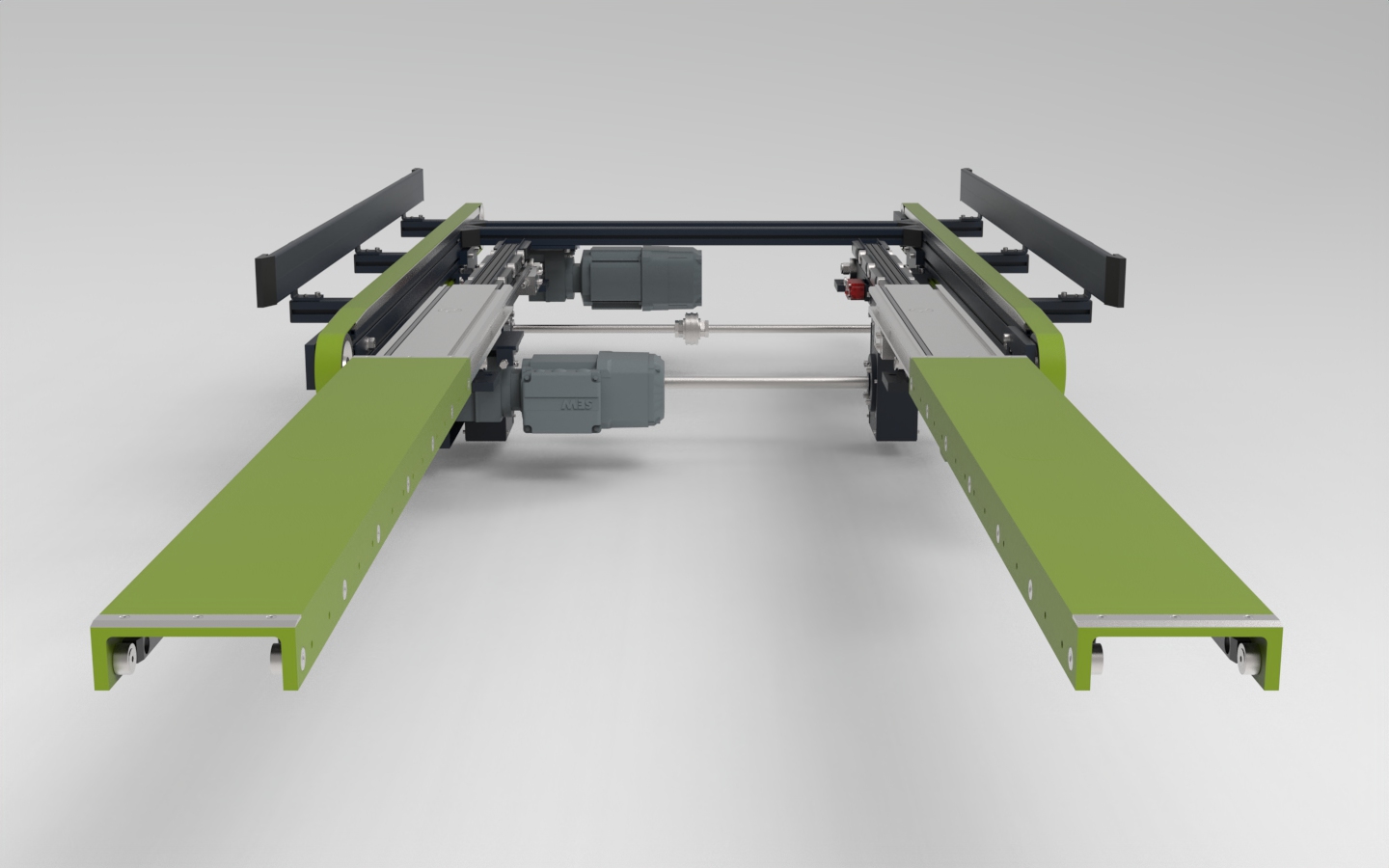

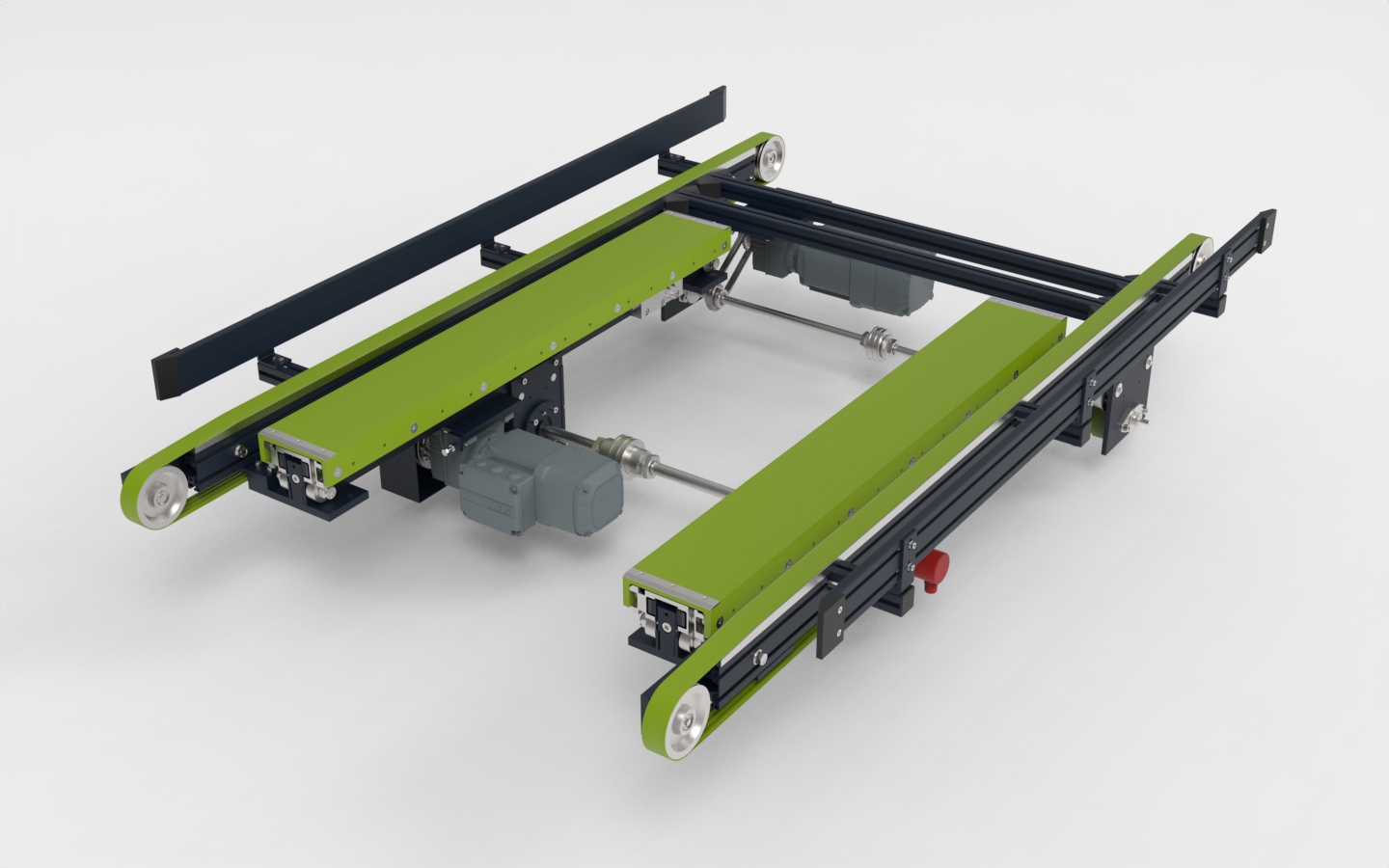

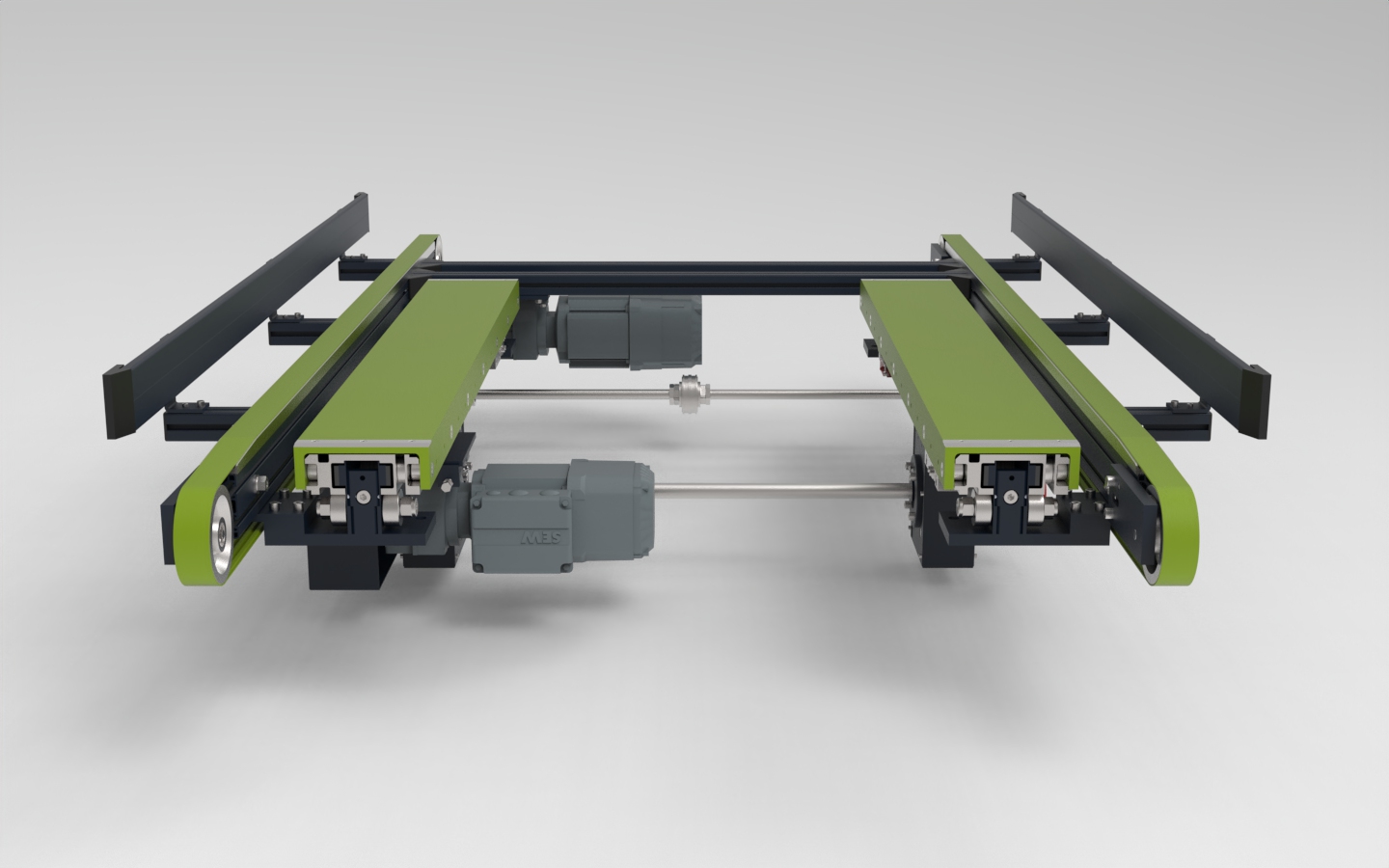

Efficient Oven Loading with Telescopic Fork and Belt Conveyor

For the automated loading and unloading of an industrial oven, our customer uses the telescopic fork F-60-166-HK-1250 with an integrated belt conveyor. The system is mounted directly on a vertical conveyor and enables precise positioning of the load carriers at the correct working level. In each cycle, four mold carriers are simultaneously inserted into or removed from the oven – an optimal solution for applications with high quantities and tight cycle times.

Seamless Integration into the Production Process

After removal from the oven, the mold carriers are automatically transported to a transfer station. There, a robot picks up the individual molds directly from the load carrier. This seamless handover reduces manual intervention and ensures that parts can be further processed quickly and safely. Thanks to the robust design and precise conveyor technology, a continuous material flow is guaranteed – regardless of temperature or environmental conditions in the oven area.

Increased Productivity through Customized Technology

Thanks to the customized design and construction of our telescopic fork with belt conveyor, the customer was able to fully automate the loading and unloading process. The result: significantly reduced cycle times, a consistent material throughput, and a noticeable reduction in operator errors. This solution impresses not only with its efficiency but also with its durability and ease of maintenance.

Would you like to learn more about our customized load handling devices?

Contact our Sales team now and let us advise you on how we can optimize your production processes as well.

Technical data:

-

Load: 280 kg

-

Stroke: 1600 + 30 mm

-

Length of the top fork: 1250 mm

-

Length of the unit: 1800 mm

-

Speed (loaded / unloaded): 30 / 87 m/min

-

Acceleration (loaded / unloaded): 0,5 / 1 m/s2

-

Self weight of the complete unit: approx. 375 kg