Perfect load handling device for buffering before and after an industrial washing system

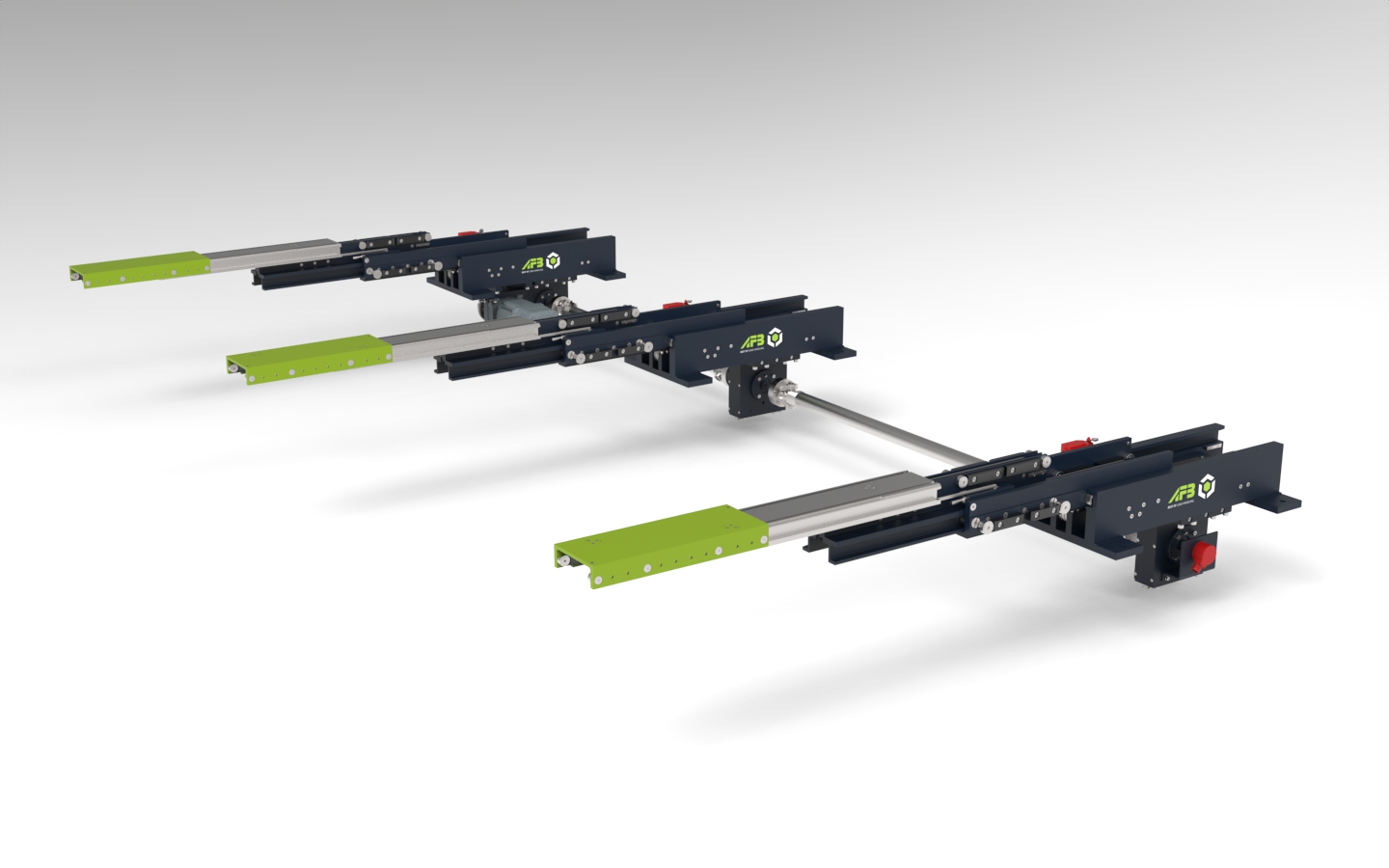

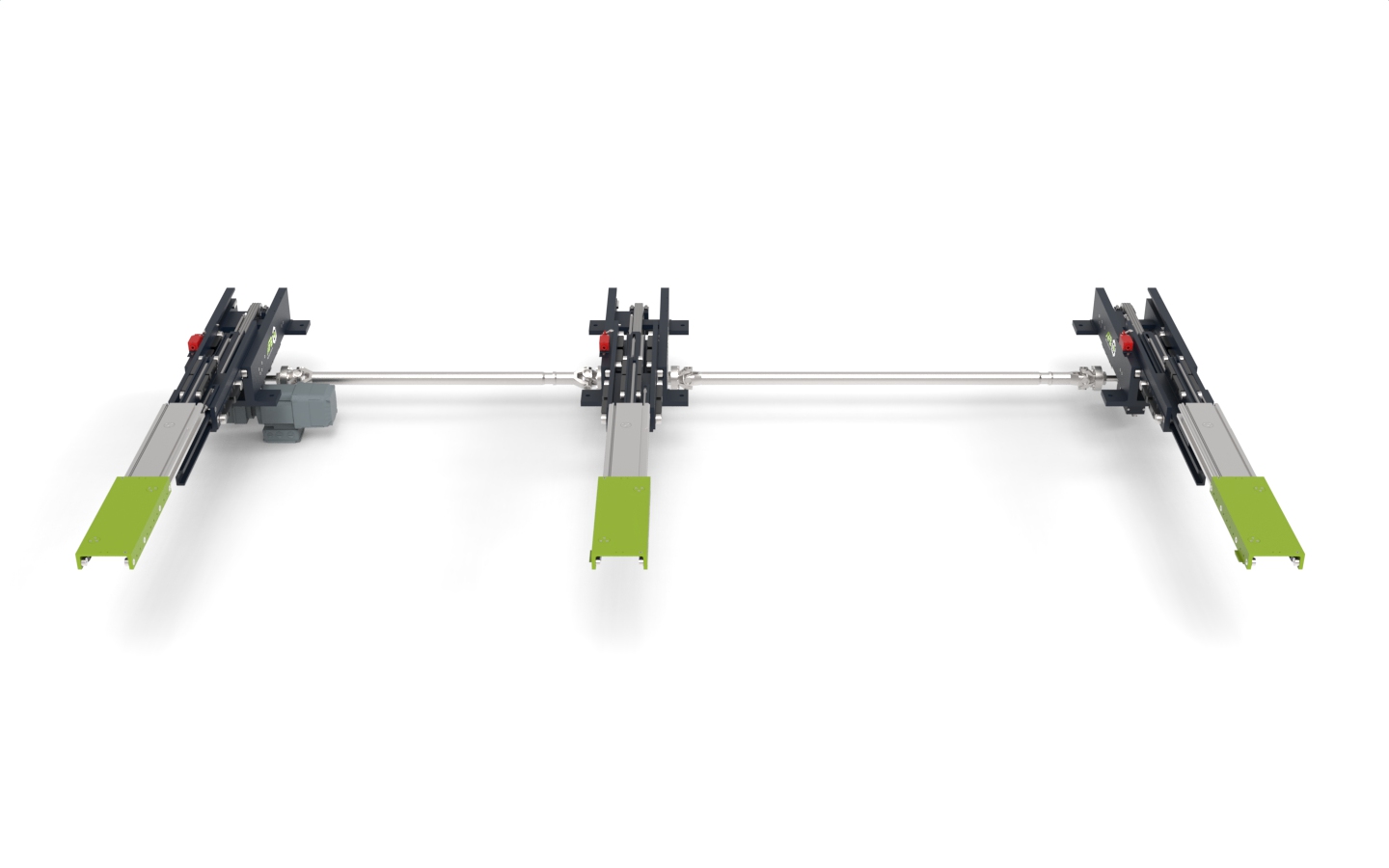

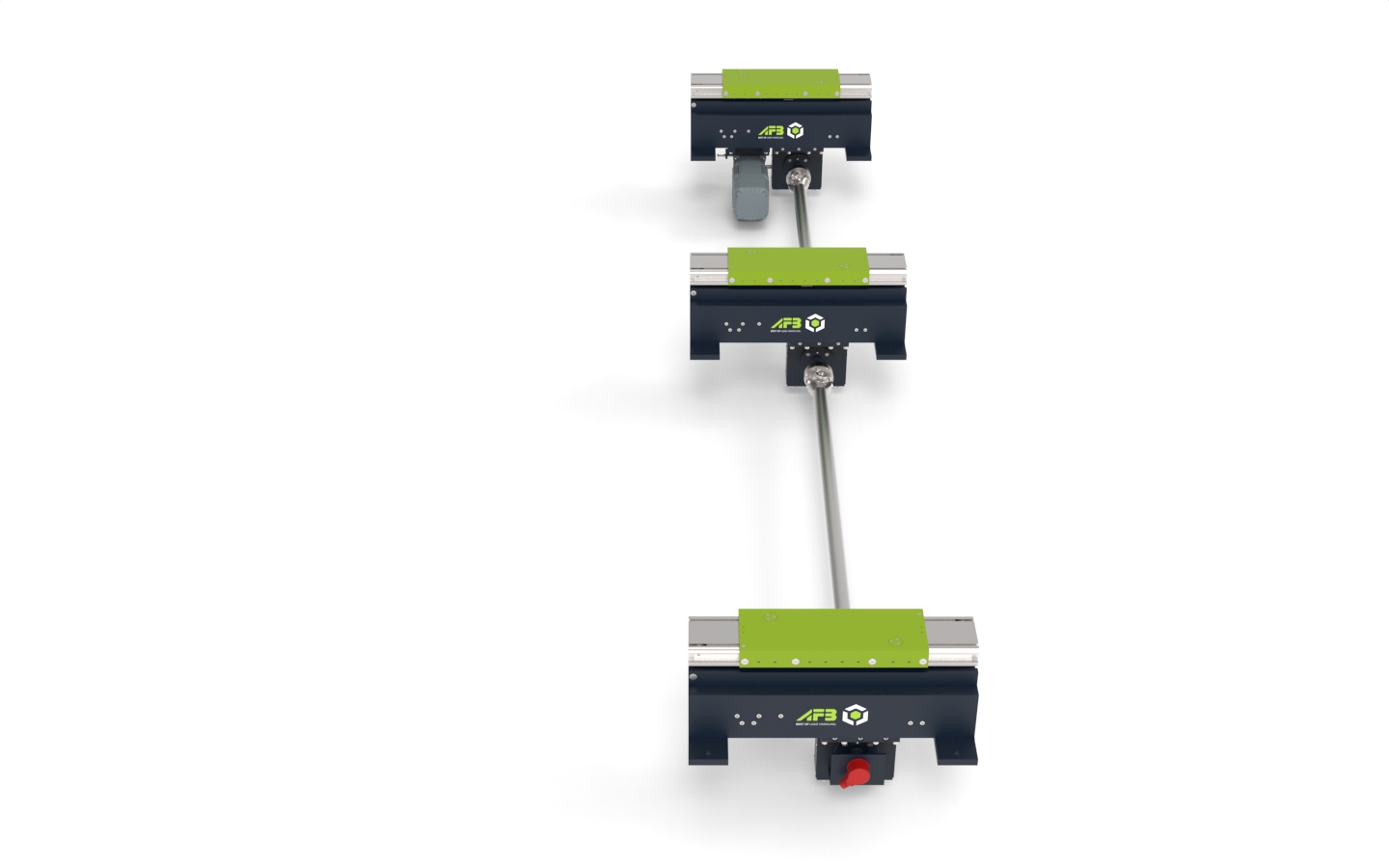

A compact solution was needed for buffer storage of load carriers in an industrial washing system. The challenge was to move and temporarily store load carriers up to 4,500 mm long efficiently in a confined space. Our specially developed telescopic fork, the D4-0.5-E-725, handels this task due to its compact design and long stroke.

Customized design for individual requirements

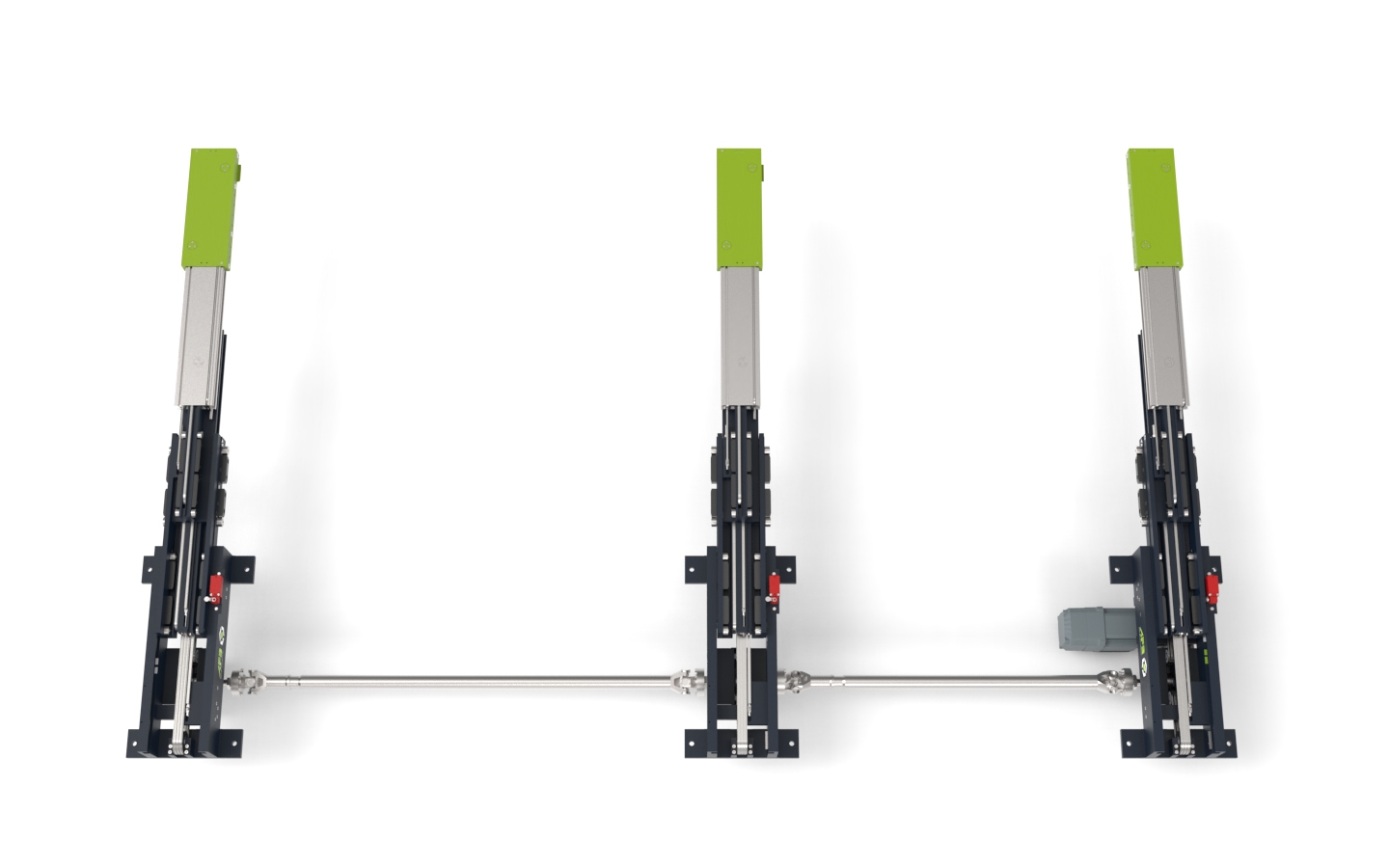

The telescopic fork was designed so that a stroke of 1,590 + 30 mm can be achieved with a fork length of only 725 mm. This is made possible by the use of a triple-depth telescopic system with four extending profiles. In addition, a customer-specific sheet metal construction was mounted on the top to ensure stable support and precise positioning of the load carriers. To transport the large-volume load carriers safely, the telescopic fork is equipped with three robust forks.

Solid performance in continuous operation

The telescopic fork was designed as a solid unit with three prongs to ensure uninterrupted operational readiness. It is optimally matched to the dimensions and weight of the load carriers. Its durable construction guarantees reliable performance even under 24/7 industrial conditions.

Contact our sales team for more information or to discuss a customized solution for your application. We look forward to advising you!

Technichal data:

-

Load weight:75 kg

-

Stroke: 1.590 + 30 mm

-

Length of the top fork: 470 mm

-

Length of the unit: 1.500 mm

-

Acceleration (loaded / unloaded): 0,5 / 1 m/s2

-

Speed (loaded / unloaded): 30 / 60 m/min

-

Self weight of the complete unit approx ca. 665 kg