Precise Handling in the Vertical Farm

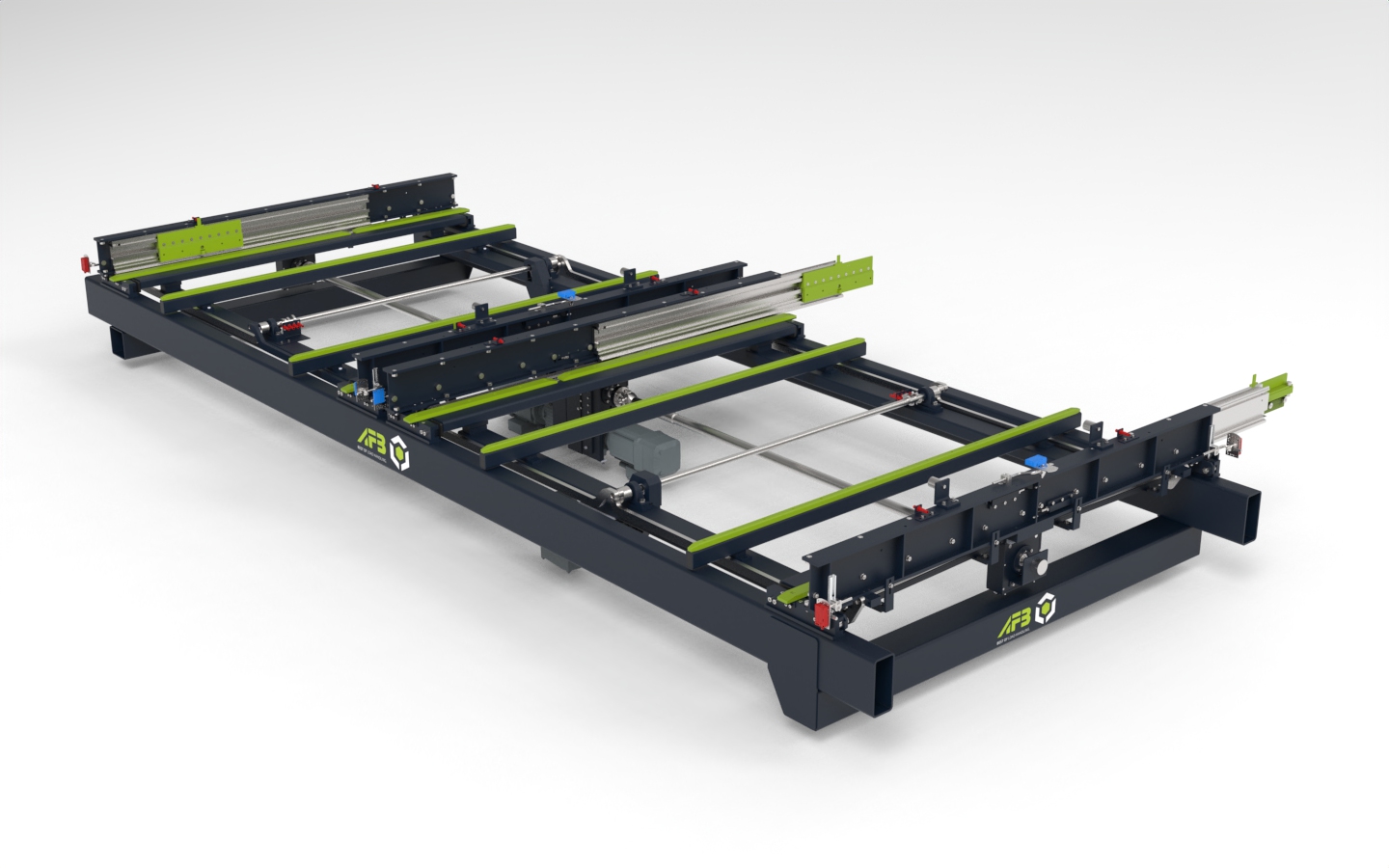

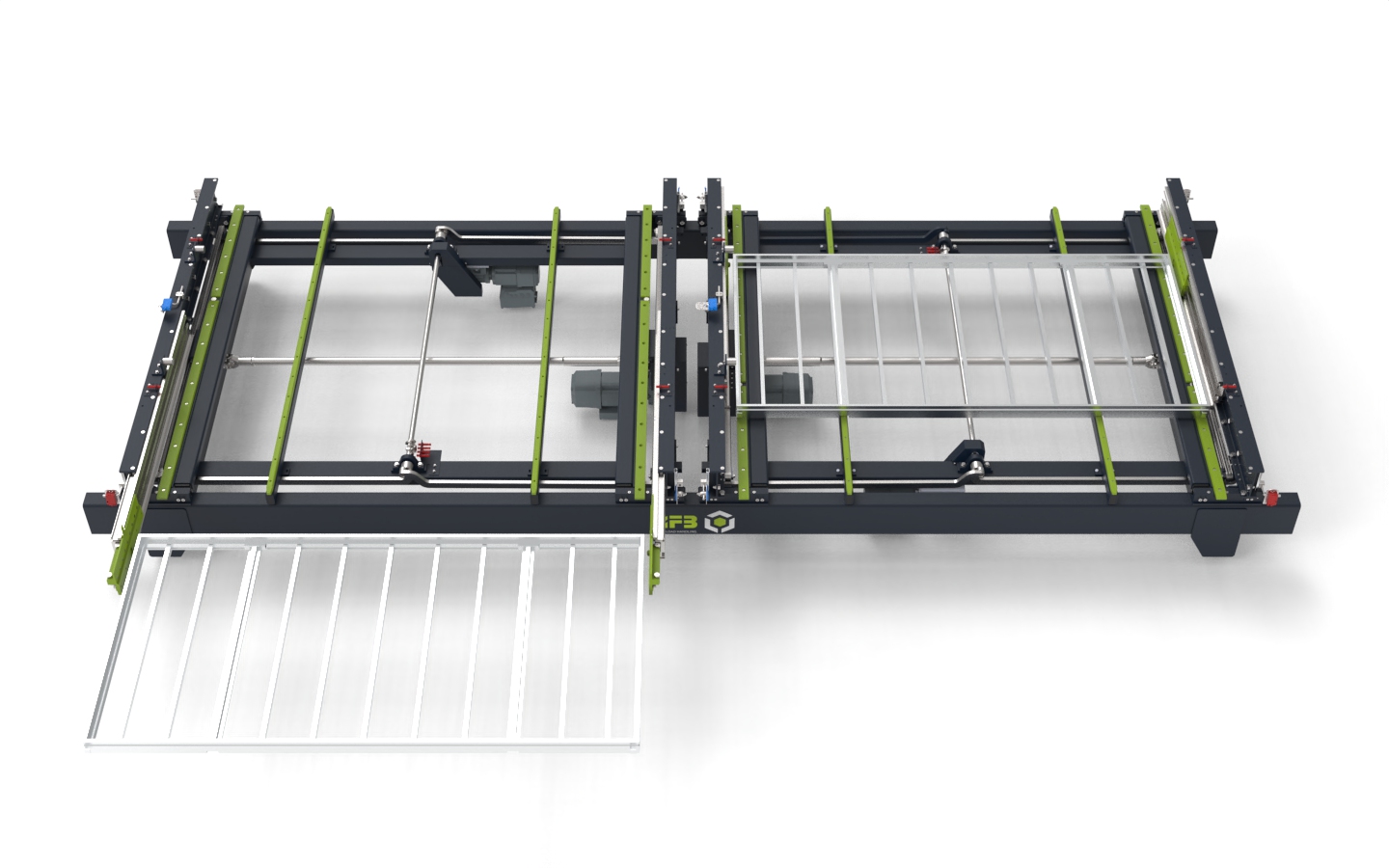

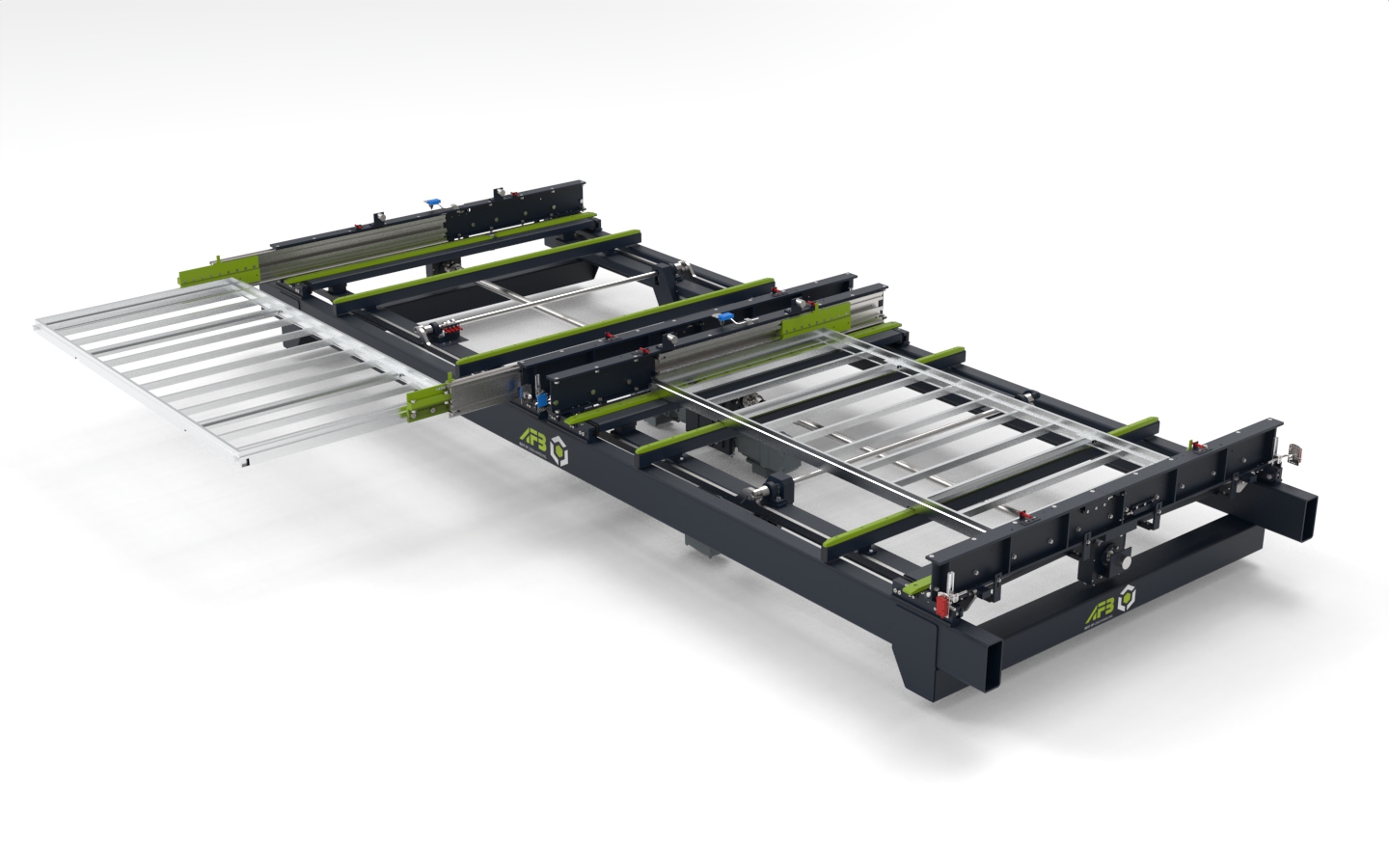

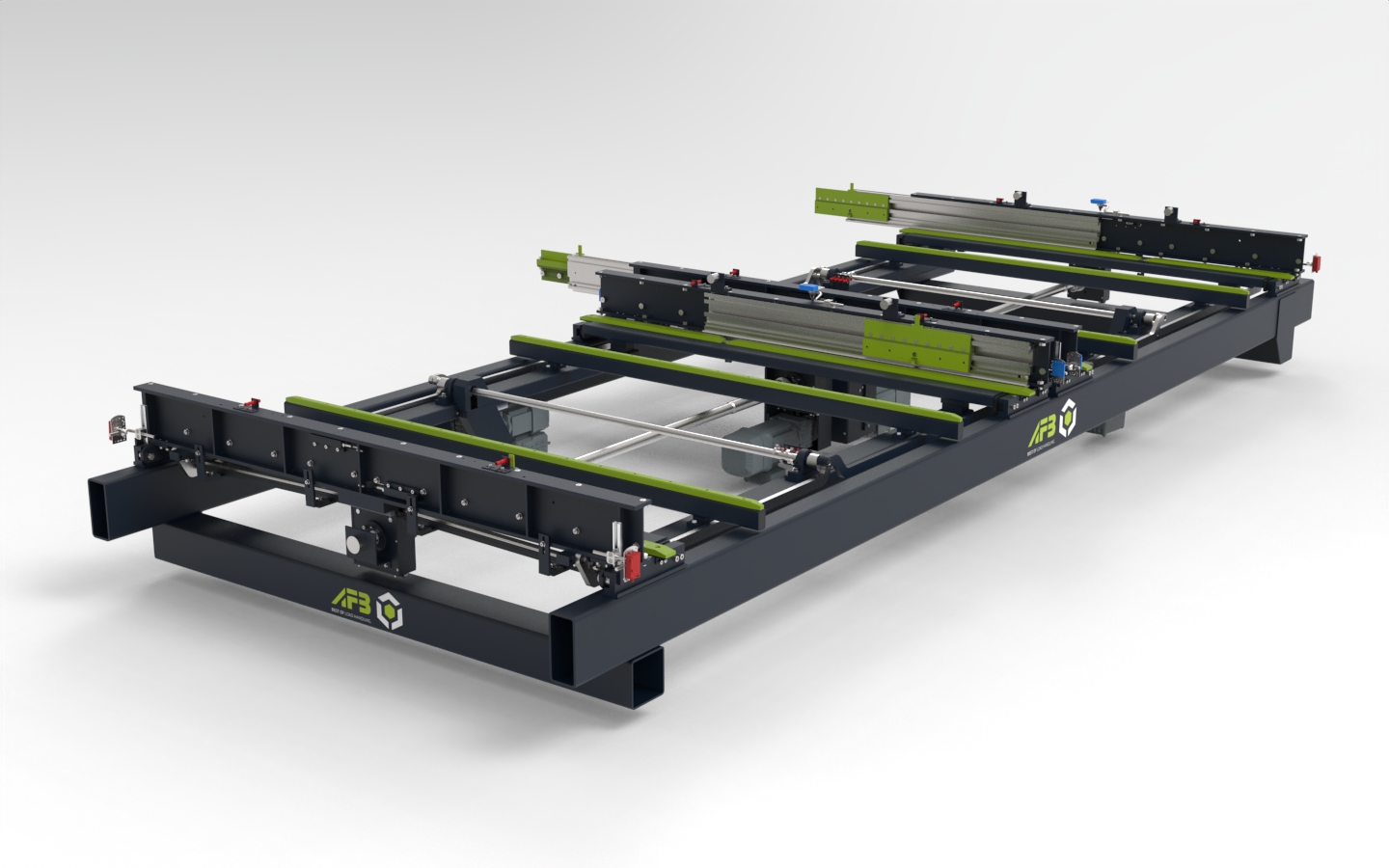

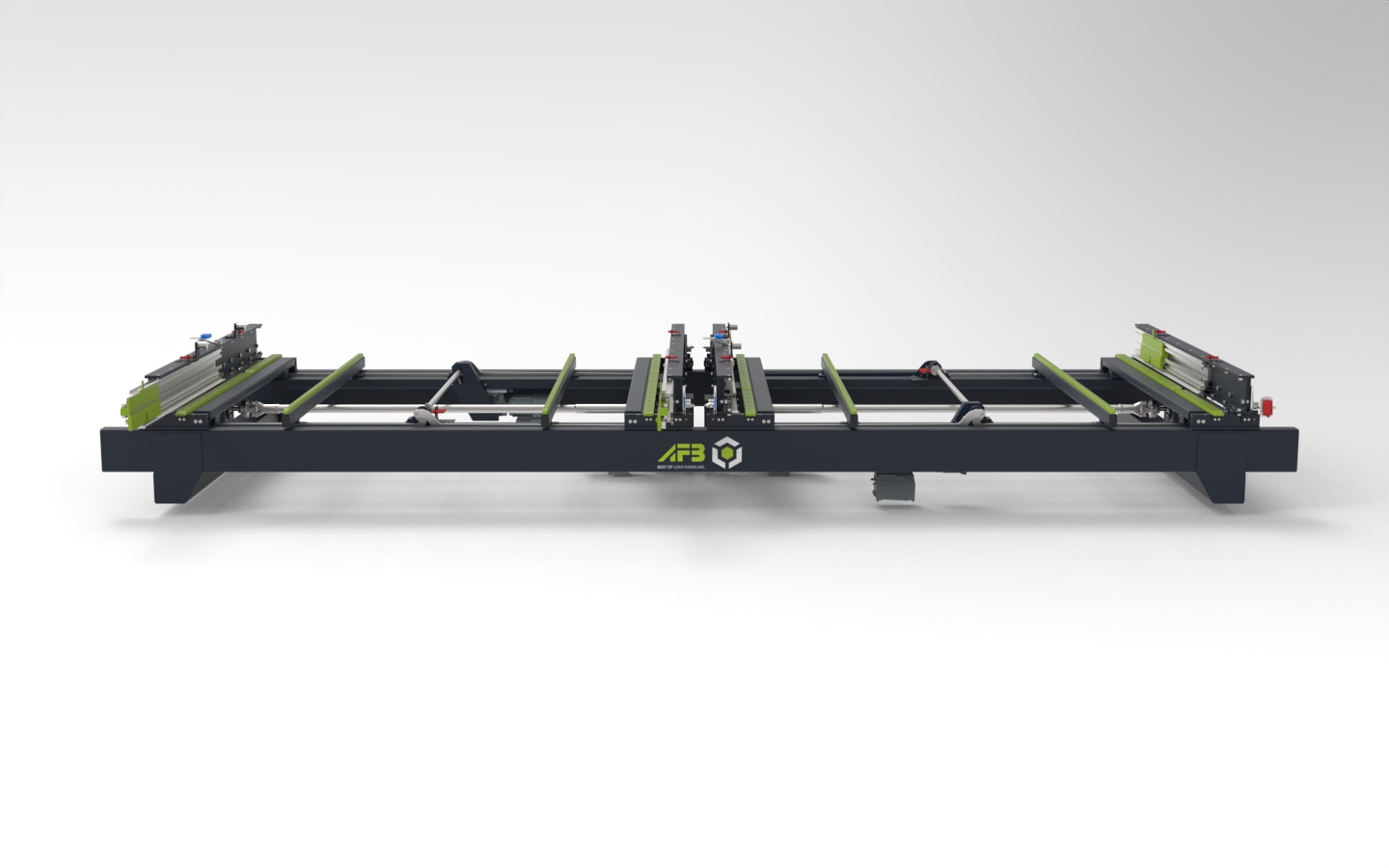

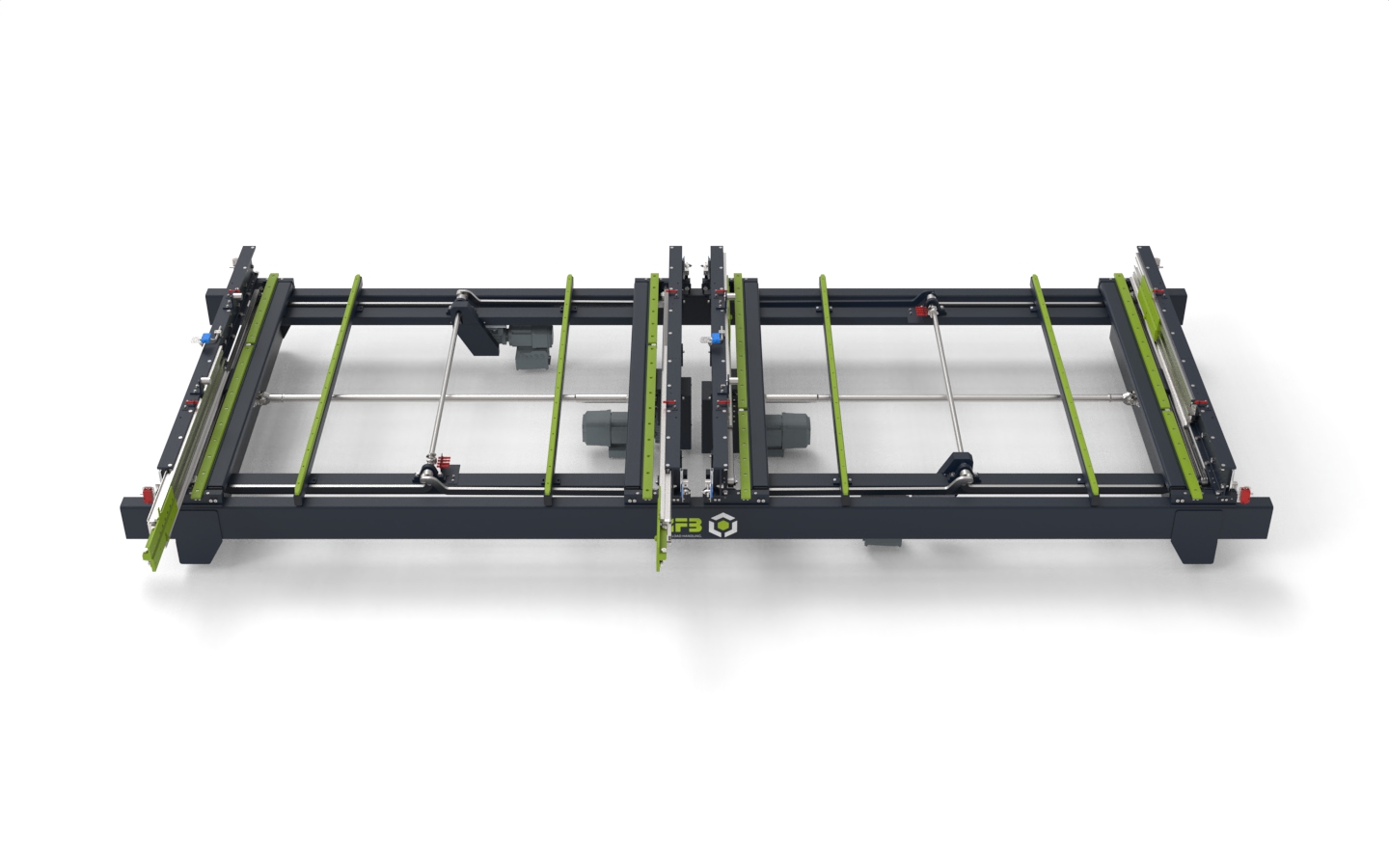

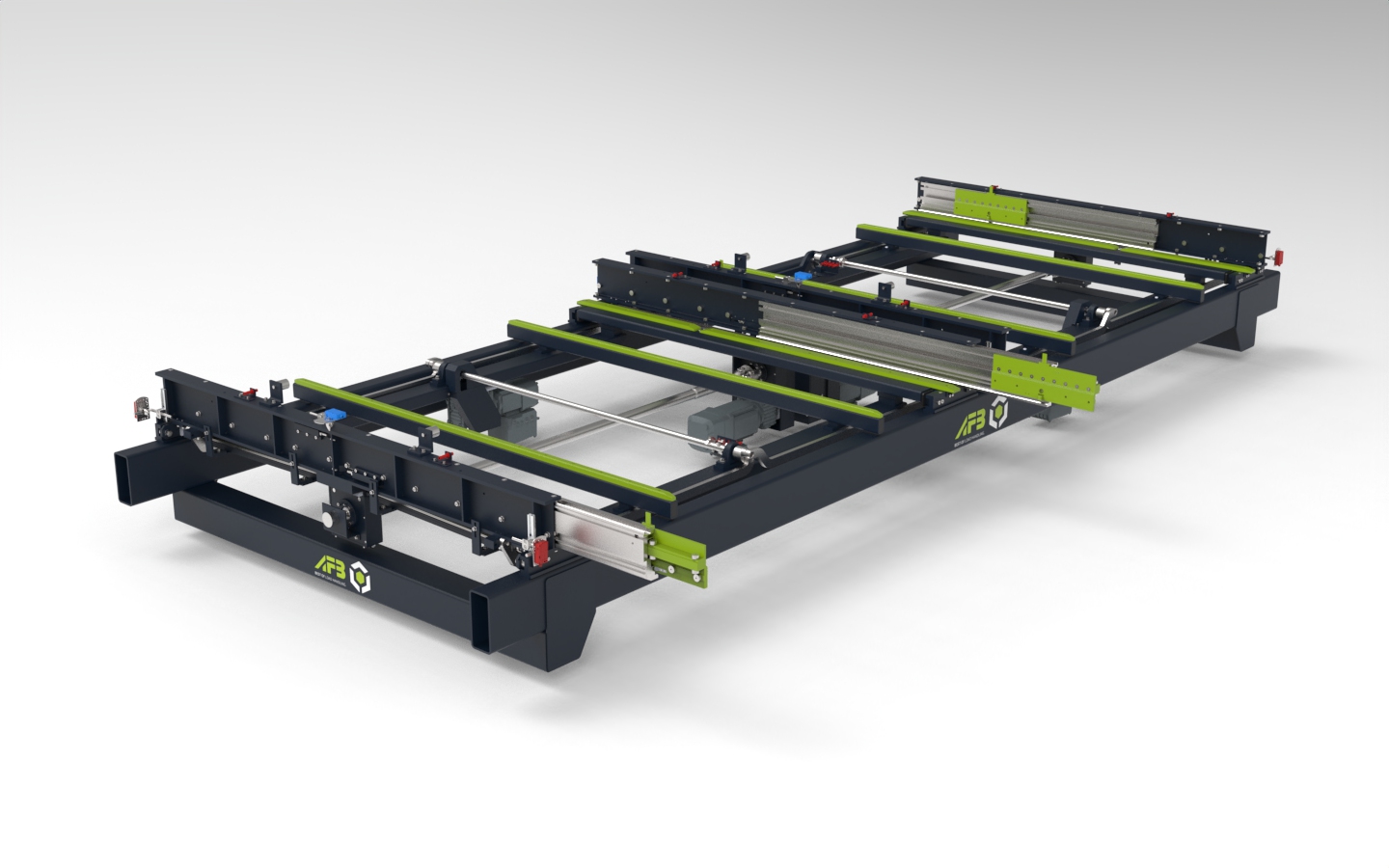

The V-K2-70-196-2300 push-pull system with extendable prongs was specially developed for use in highly automated greenhouses, also known as vertical farms. The focus of the development was the gentle yet efficient handling of the benches, which is a particular requirement of these types of greenhouse. These trays, which are filled with plants and nutrient liquid, can weigh up to 180 kg and are picked up and delivered by the system on both sides.

Careful Transport for Maximum Process Reliability

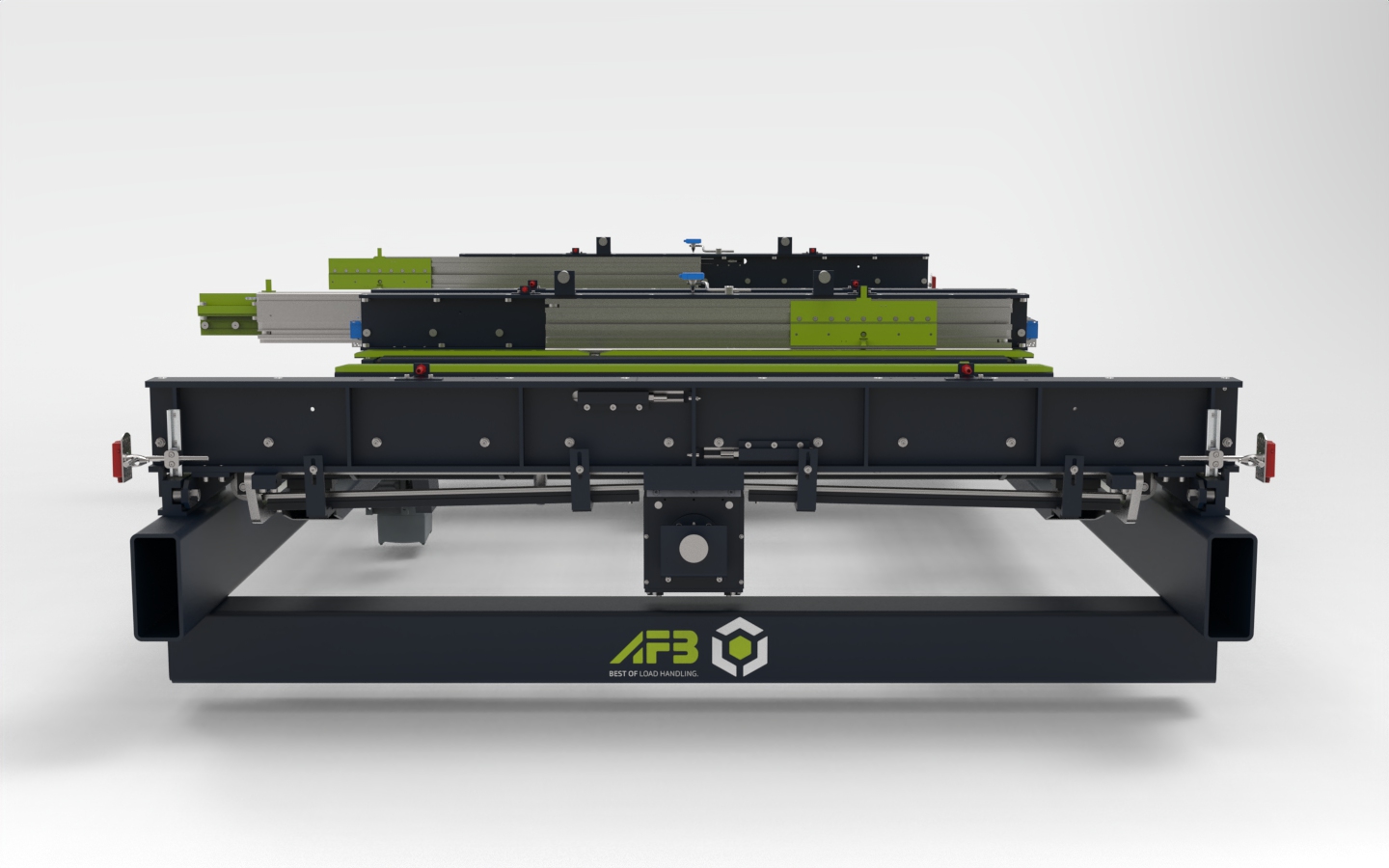

To prevent the sensitive nutrient liquid from spilling in the benches, the push-pull system dispenses it with a smooth and fluend motion. During delivery, the device precisely pushes the trays into their designated positions. Two of these systems are installed on the lifting frame of the stacker crane for higher flexibility during transfers. Due to the food-grade design, the system meets the high hygiene standards essential for growing lettuce and other crops.

Efficiency at All Levels

The benches are stored across 16 levels within a cultivation area spanning over 1,000 square metres. This efficient use of space allows for high productivity and precise process control. The V-K2-70-196-2300 push-pull system is a key component for the successful operation of modern vertical farming facilities due to its combination of load capacity, gentle movement and hygienic design.

Would you like to find out more about our automated intralogistics solutions for vertical farming? Get in touch with our sales team, who will be happy to advise you.

Technical data:

-

Load: 180 kg

-

Stroke: 1505 + 30 mm

-

Length of the top fork: 500 mm

-

Length of the unit: 2397 mm

-

Adjustment range of prongs: 2400 mm – 2454 mm

-

Speed telescopic fork (loaded / unloaded): 30 / 60 m/min

-

Acceleration telescopic fork (loaded / unloaded): 0,3 / 1 m/s2

-

Self weight of the complete unit: approx. 300 kg