Tailor-Made Solution for Efficient Baggage Logistics

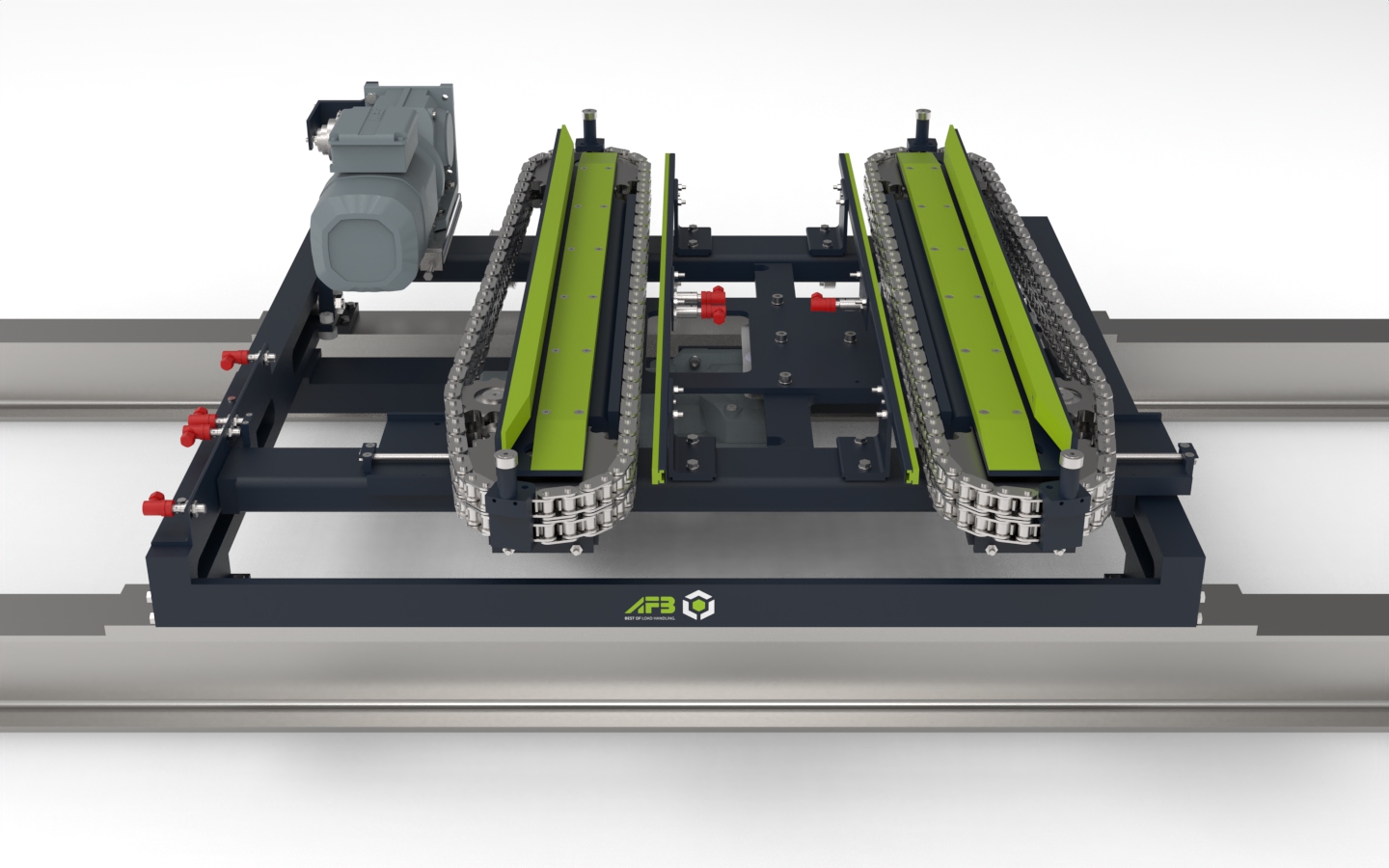

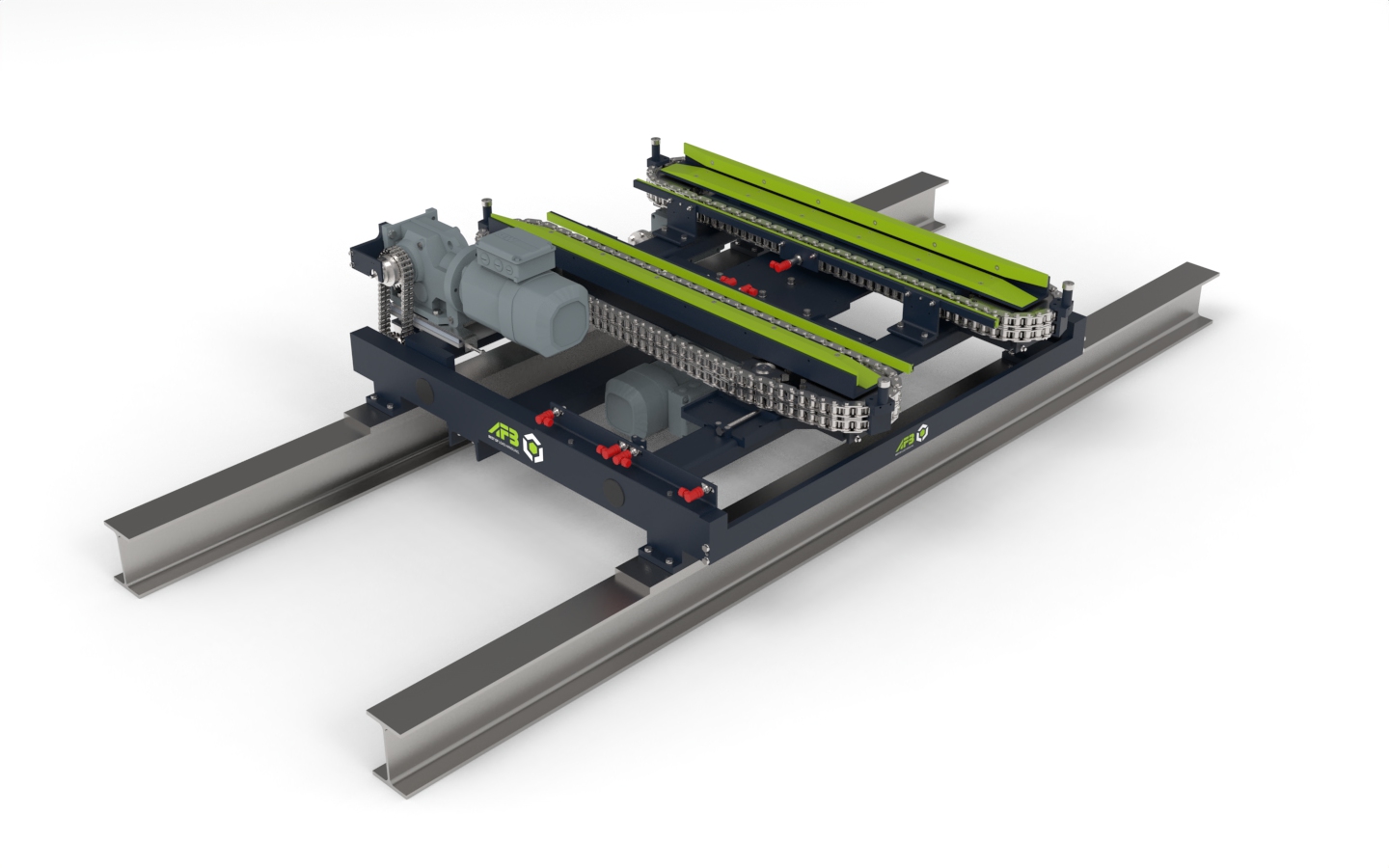

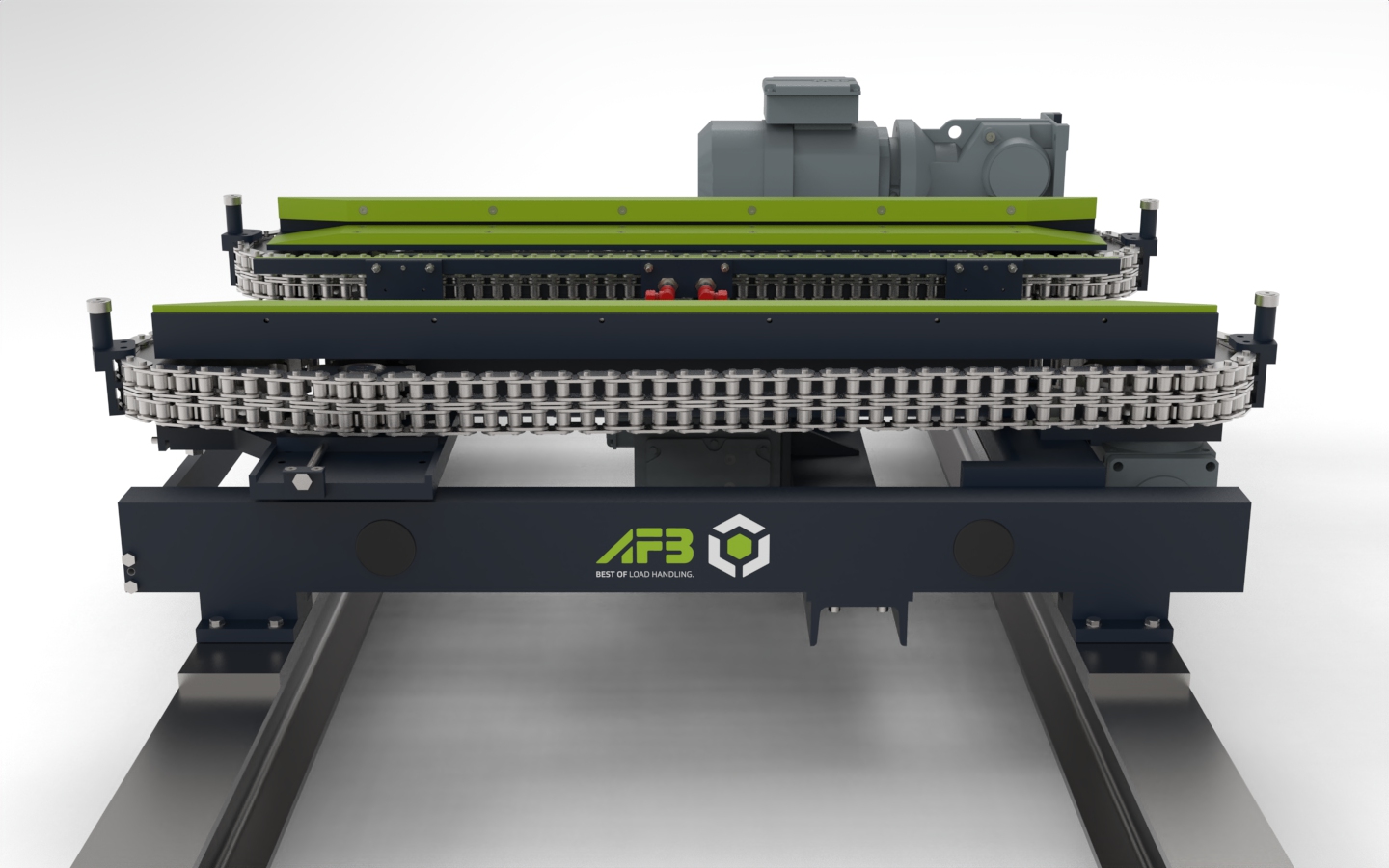

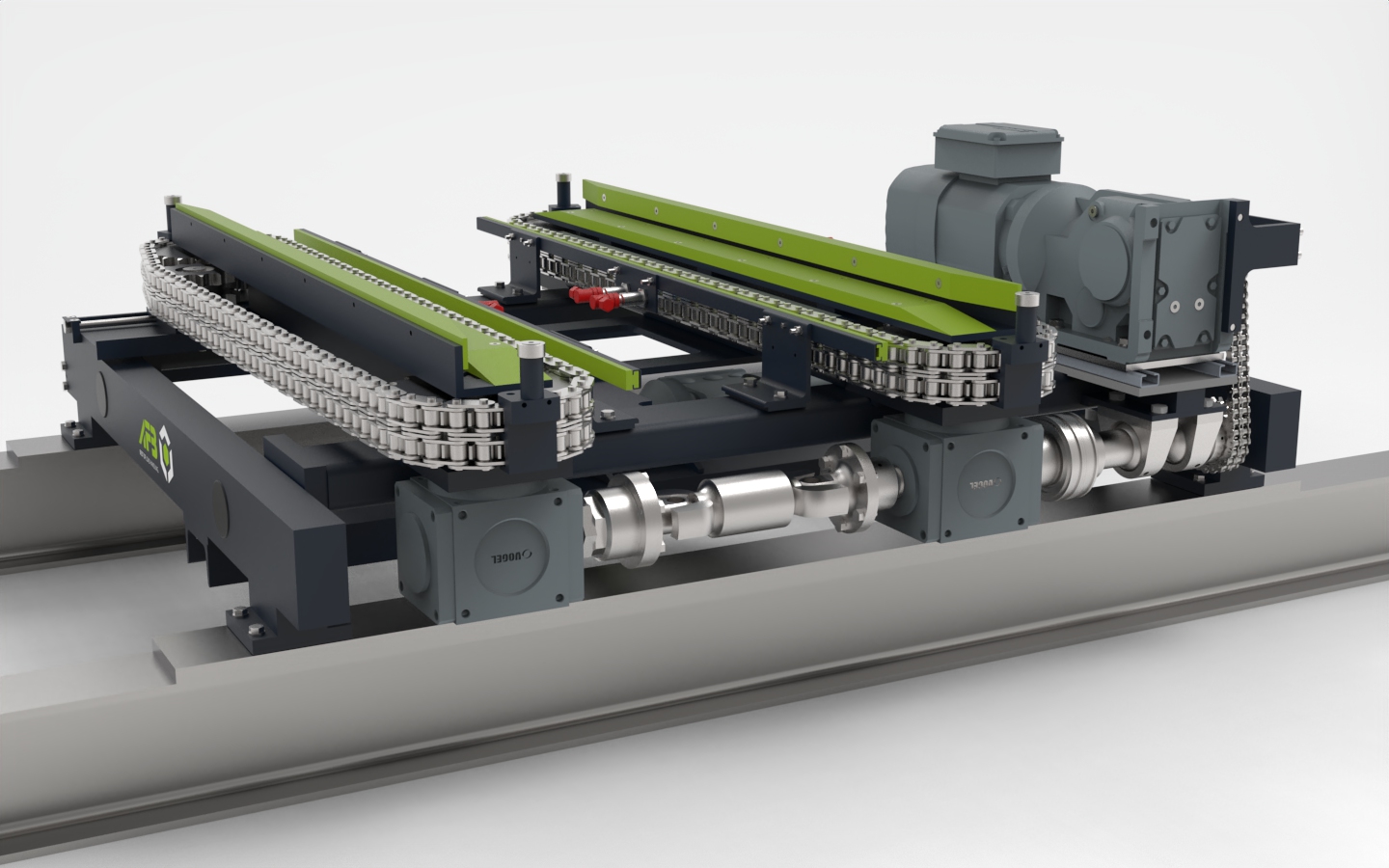

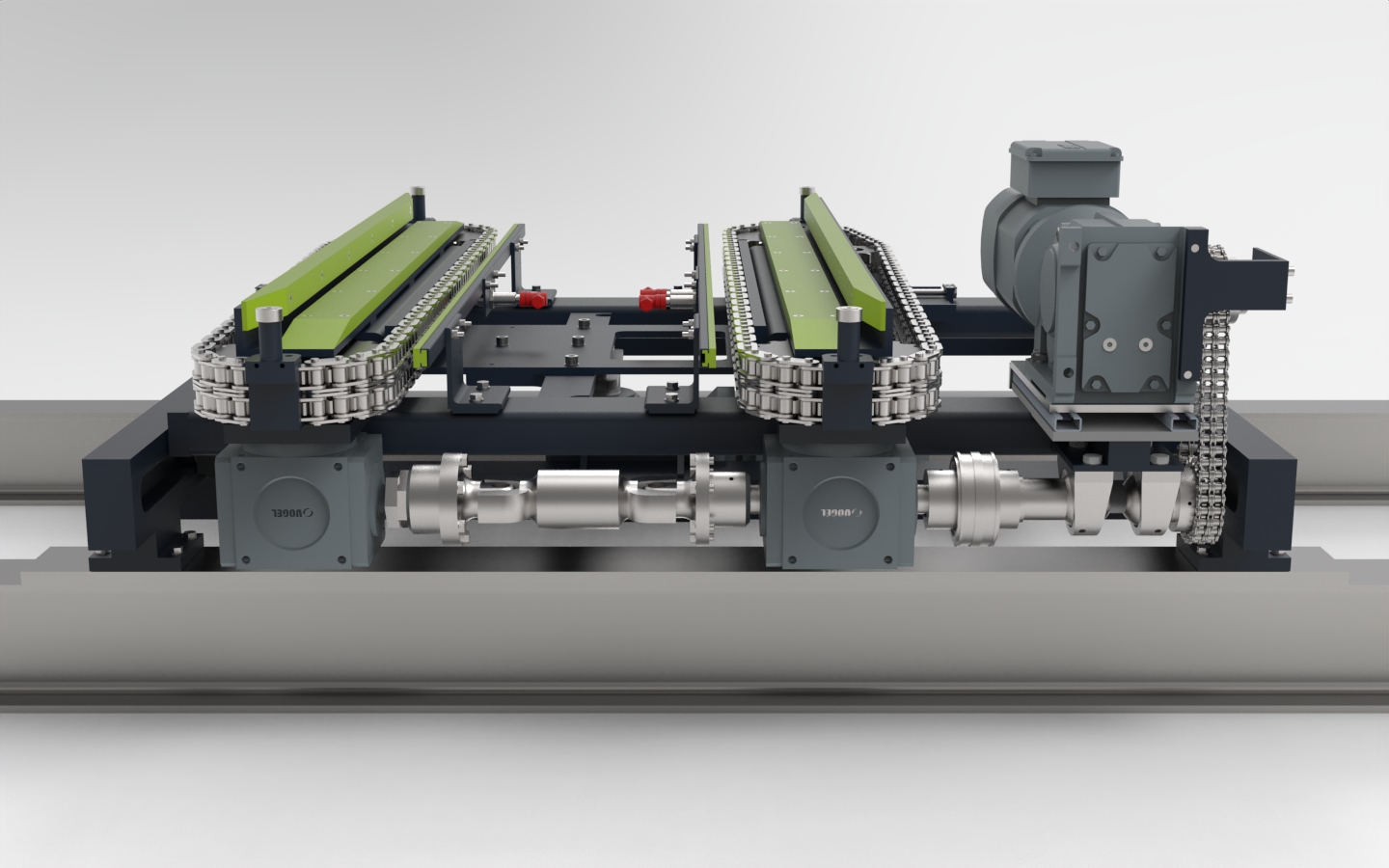

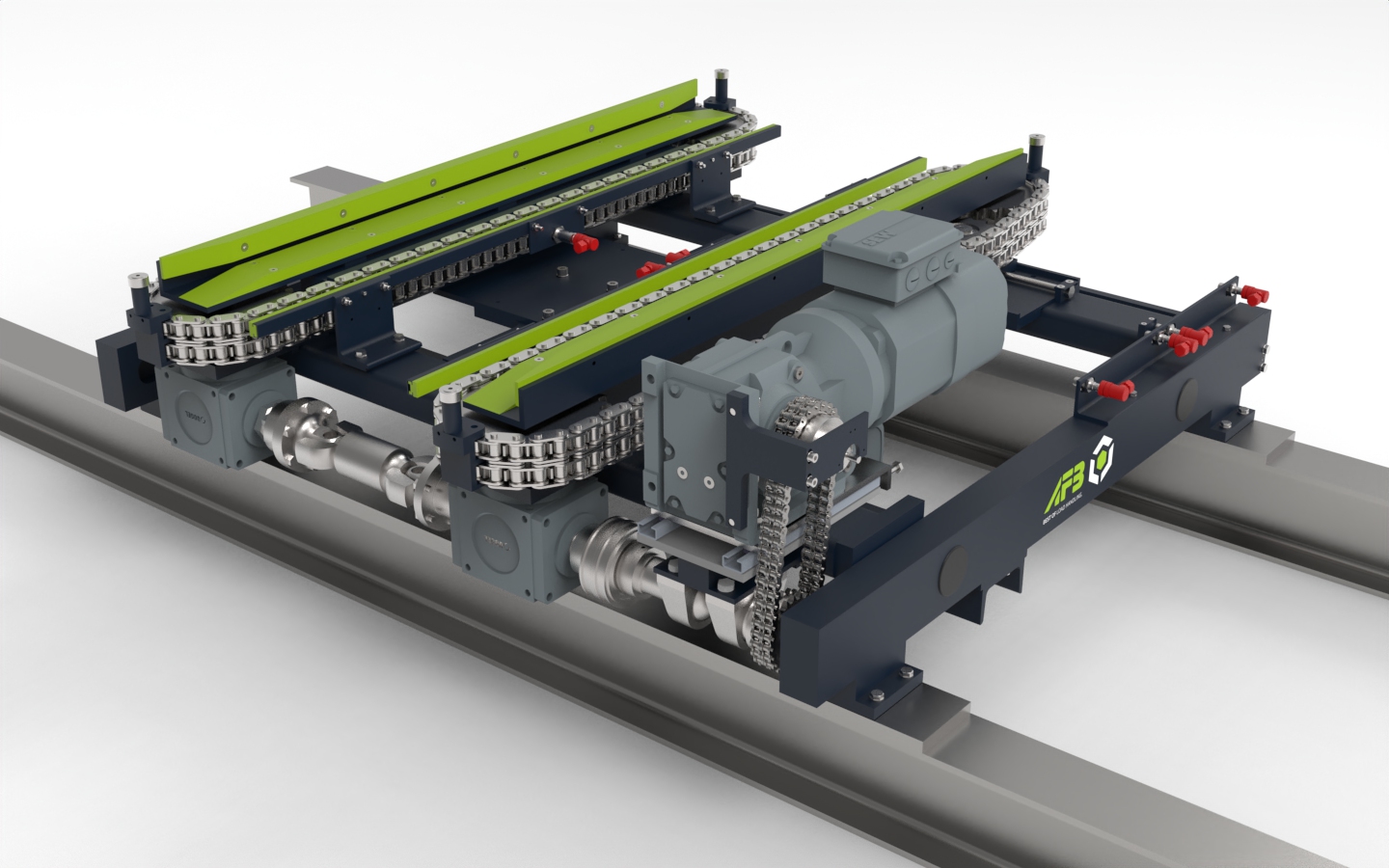

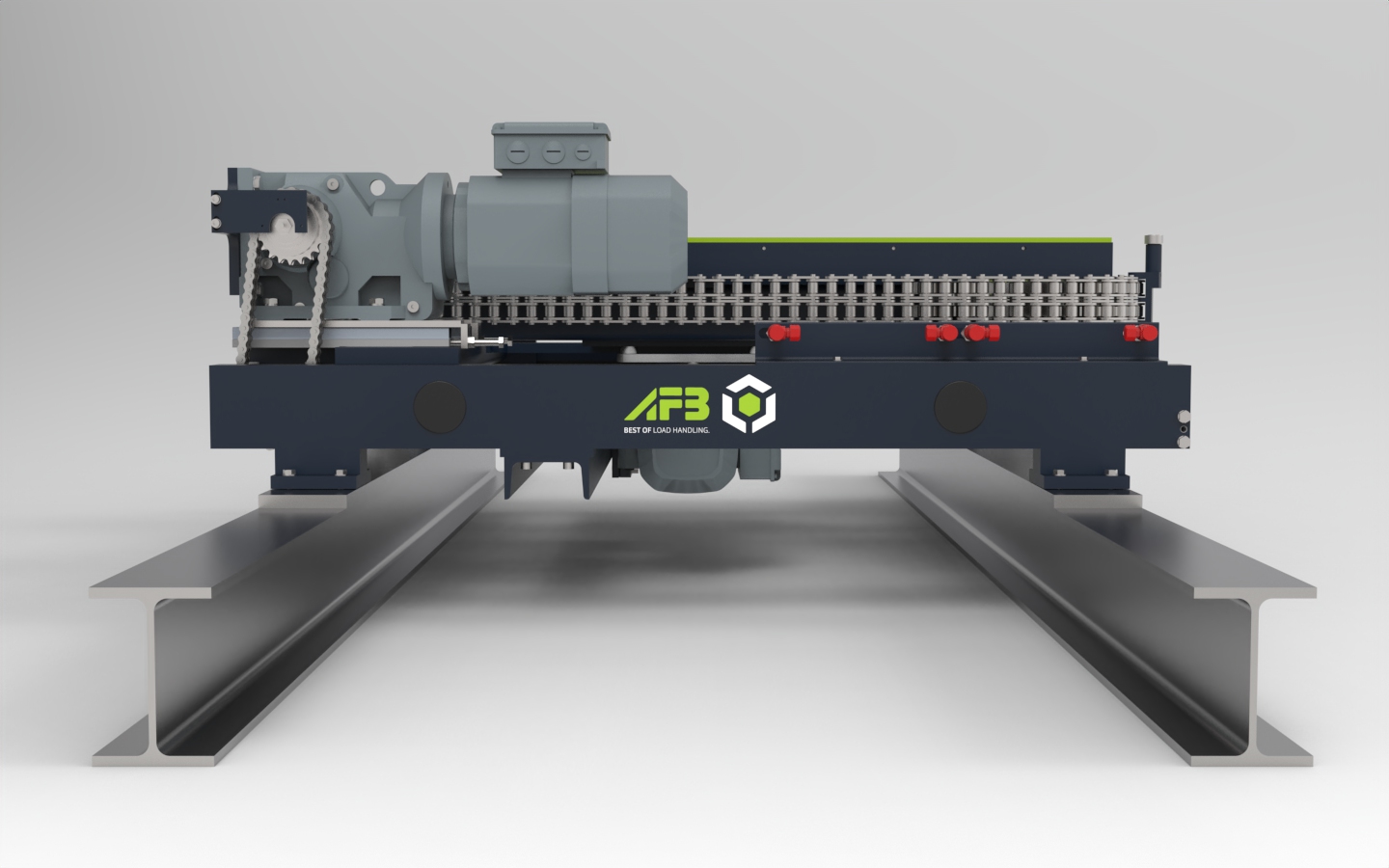

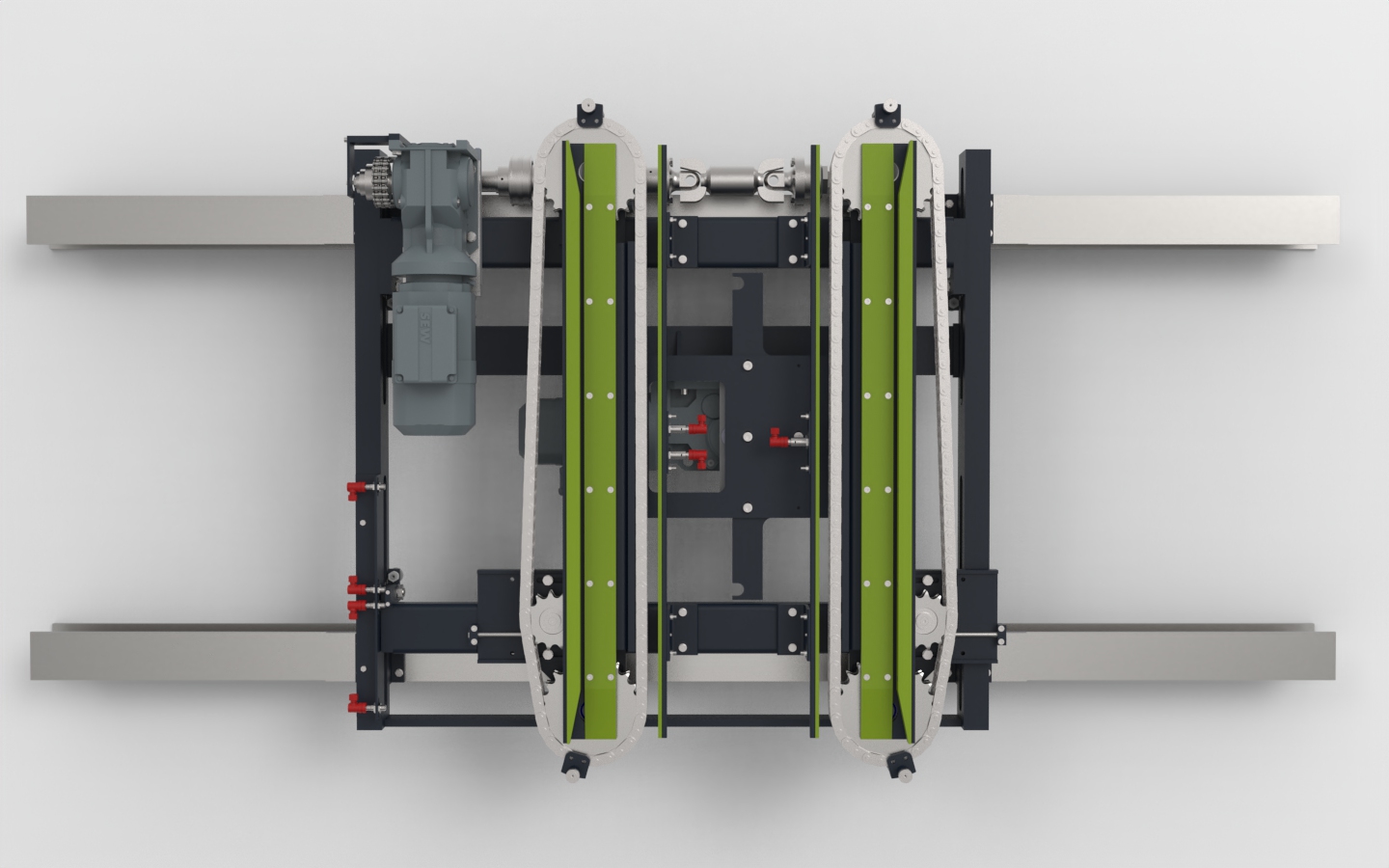

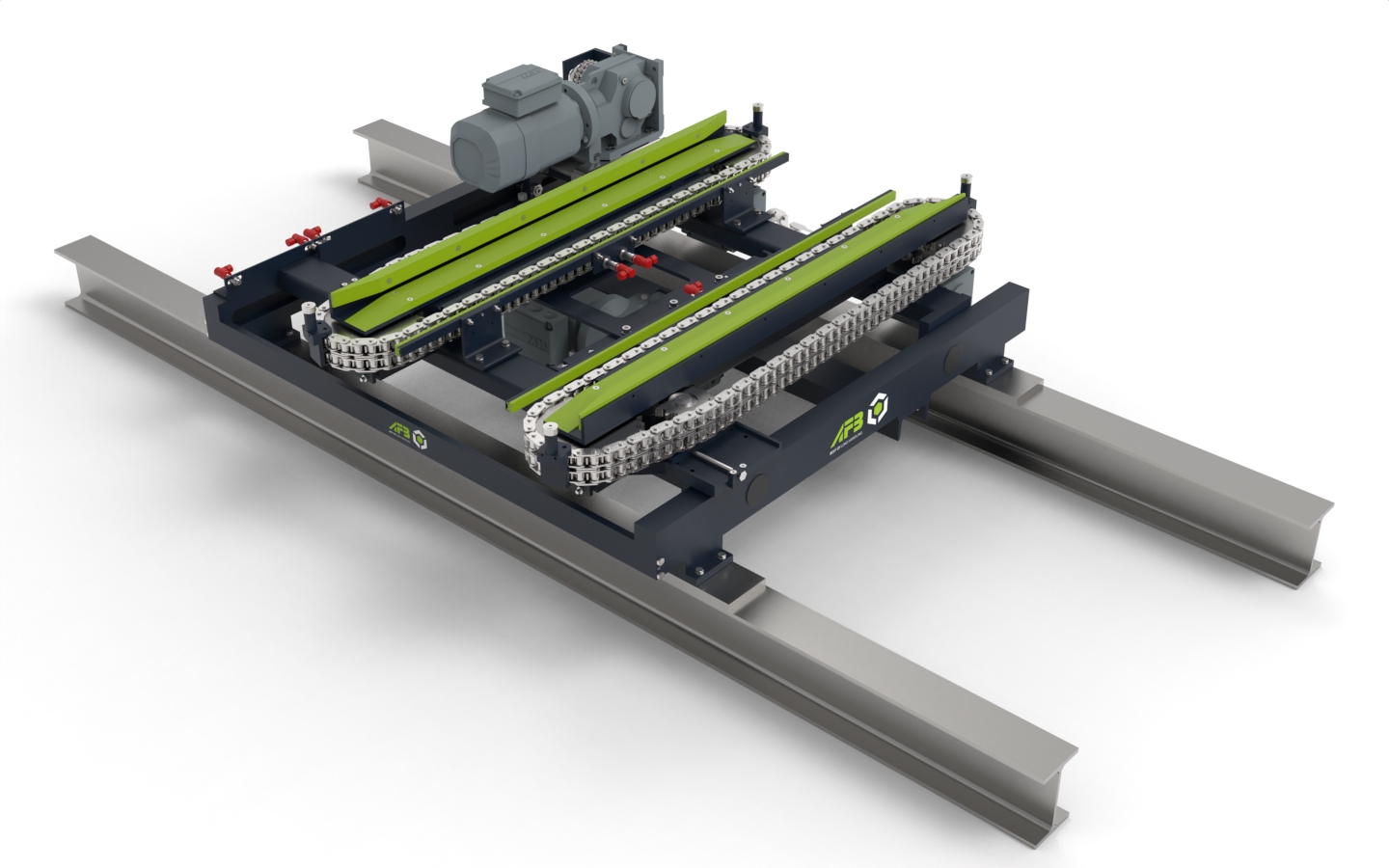

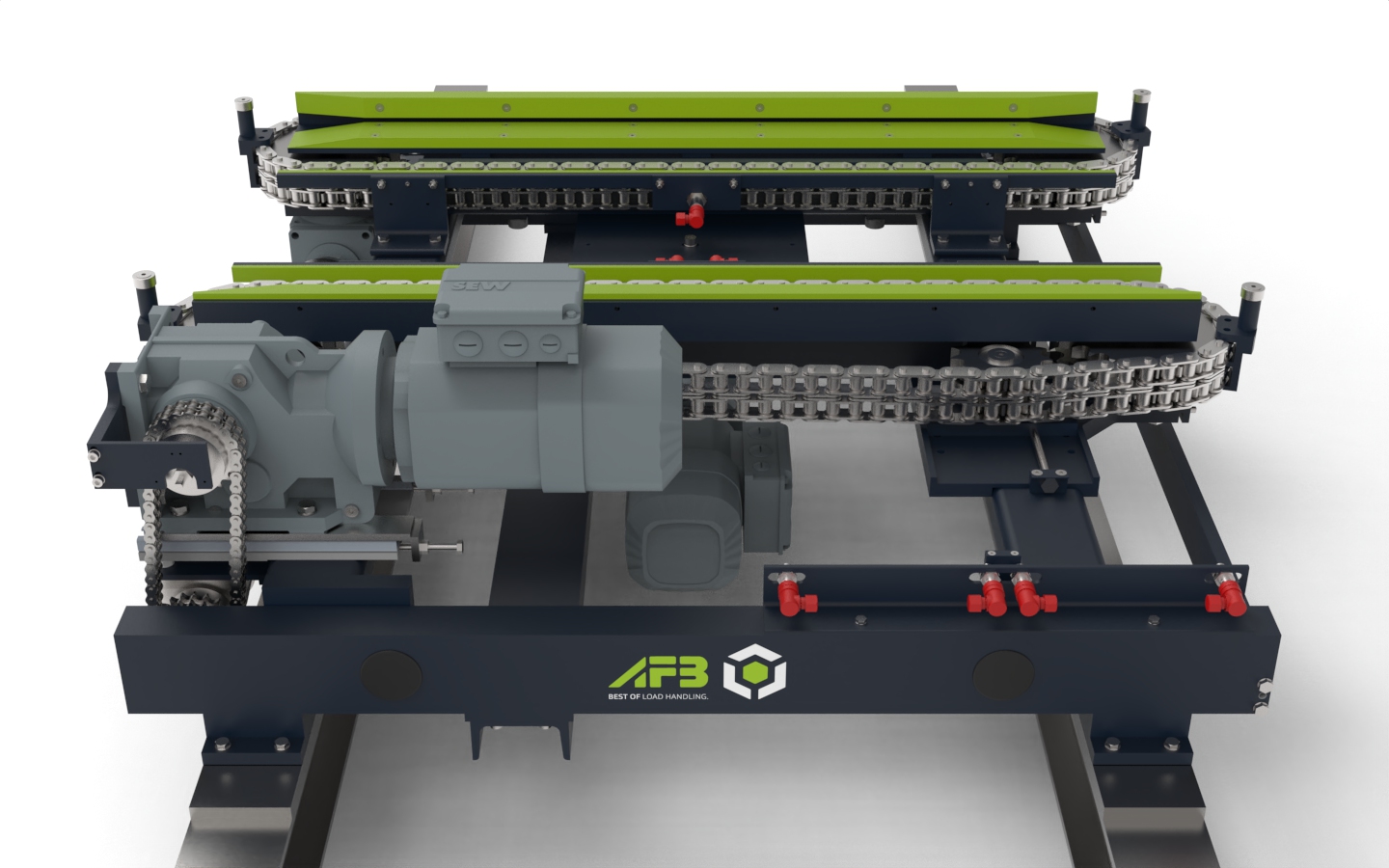

The 150–1300 push-pull system was specifically developed for use in an automated high-bay warehouse belonging to an international airline in Saudi Arabia. The aim was to safely and efficiently store luggage in standardized metal boxes measuring 600 x 1200 x 400 mm. The system was custom-designed to match the customer’s requirements and fulfils the high logistical demands of daily operations.

Reliability in 24/7 Operation

Our push-pull system is designed for continuous operation, 24 hours a day, 7 days a week. With its robust construction and precise control, it ensures a smooth flow of materials in the high-bay warehouse, even under demanding conditions. This consistently high level of process reliability enables the airline to handle its baggage efficiently and on time.

Quality That Makes the Difference

In particular, international airports are subject to the highest standards in terms of reliability, safety and quality. The 150-1300 push-pull system meets these requirements due to its robust design and ability to operate continuously. This solution has boosted the efficiency of baggage logistics and greatly enhanced operational safety.

Would you like to optimise your intralogistics, too? Get in touch with our sales team, who will be happy to advise you on bespoke solutions for your needs.

Technical Data:

-

Load carrier: metal tray

-

Load weight: 150 kg

-

Relative stroke: 202 mm

-

Length of the unit: 1280 mm

-

Speed: 40/min

-

Acceleration: 0,5 m/s2

-

Self weight of the complete unit: approx. 410 kg