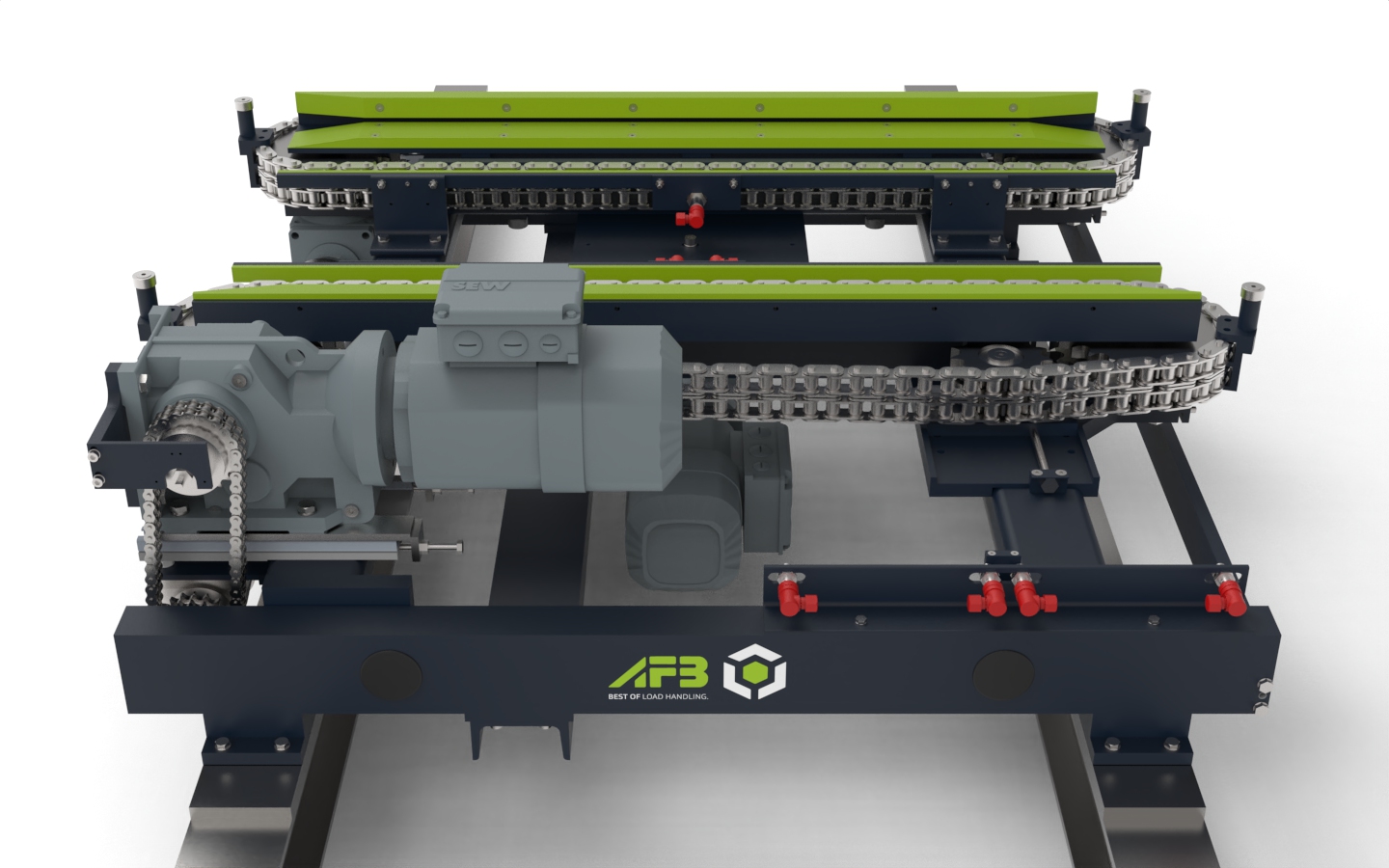

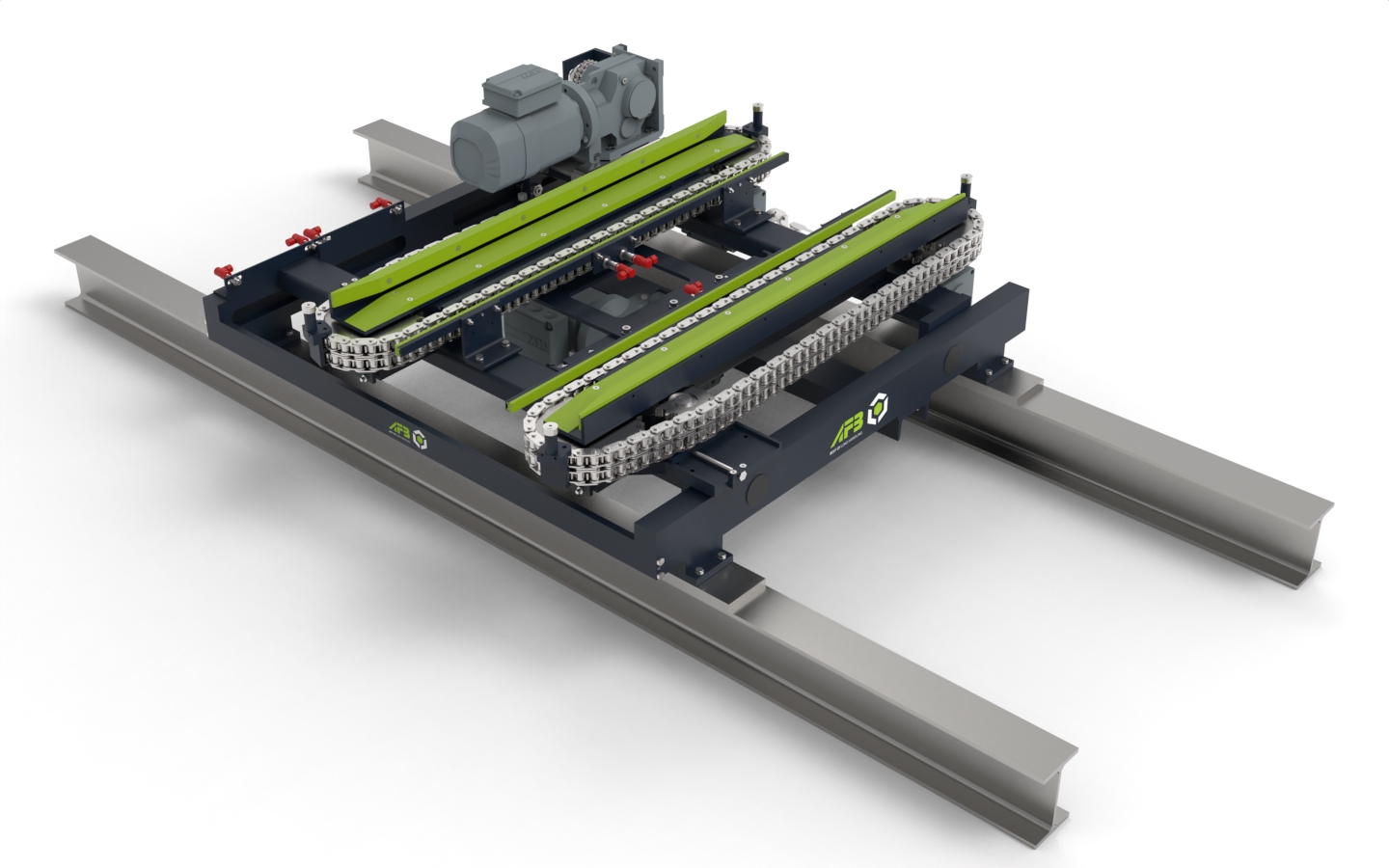

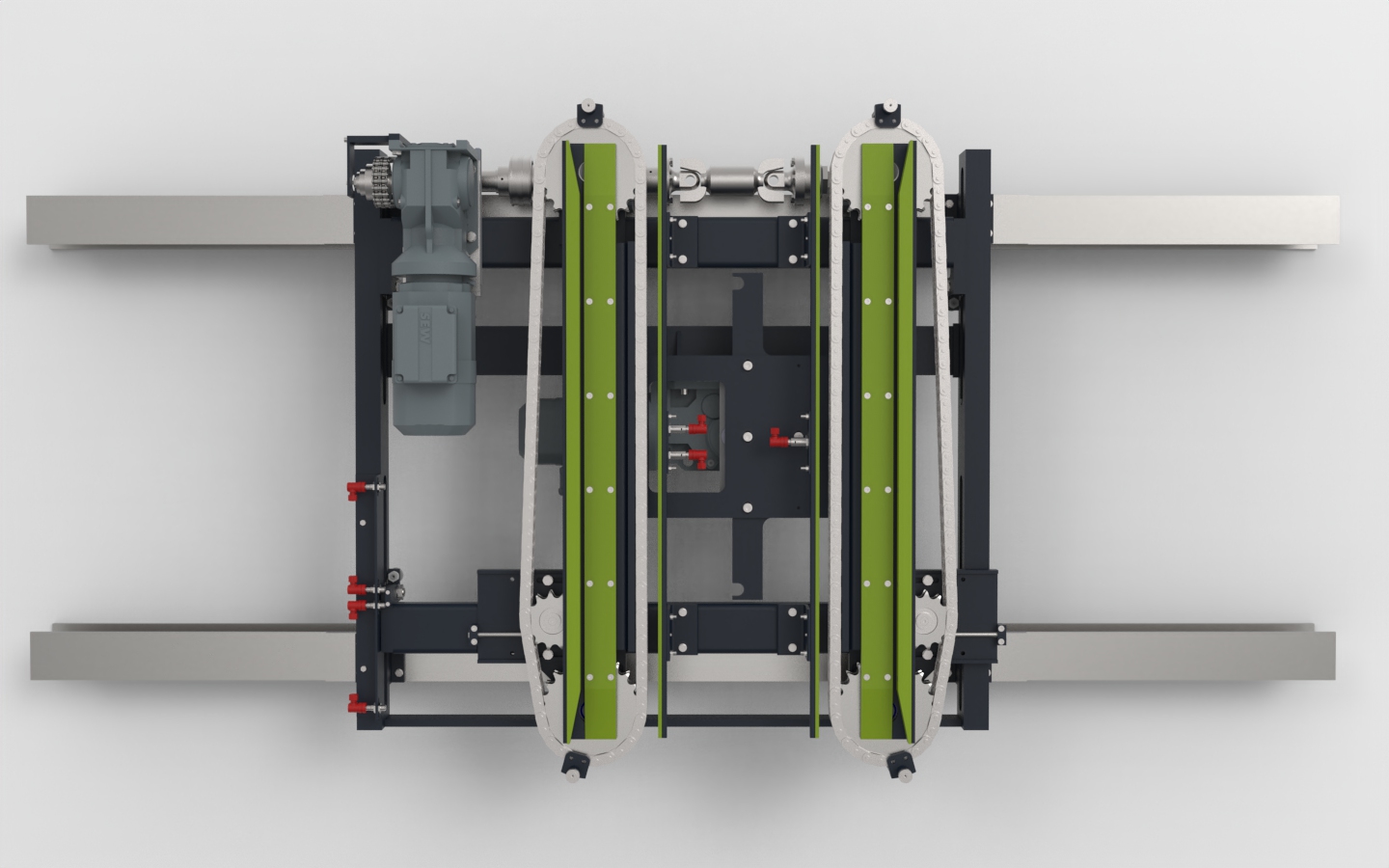

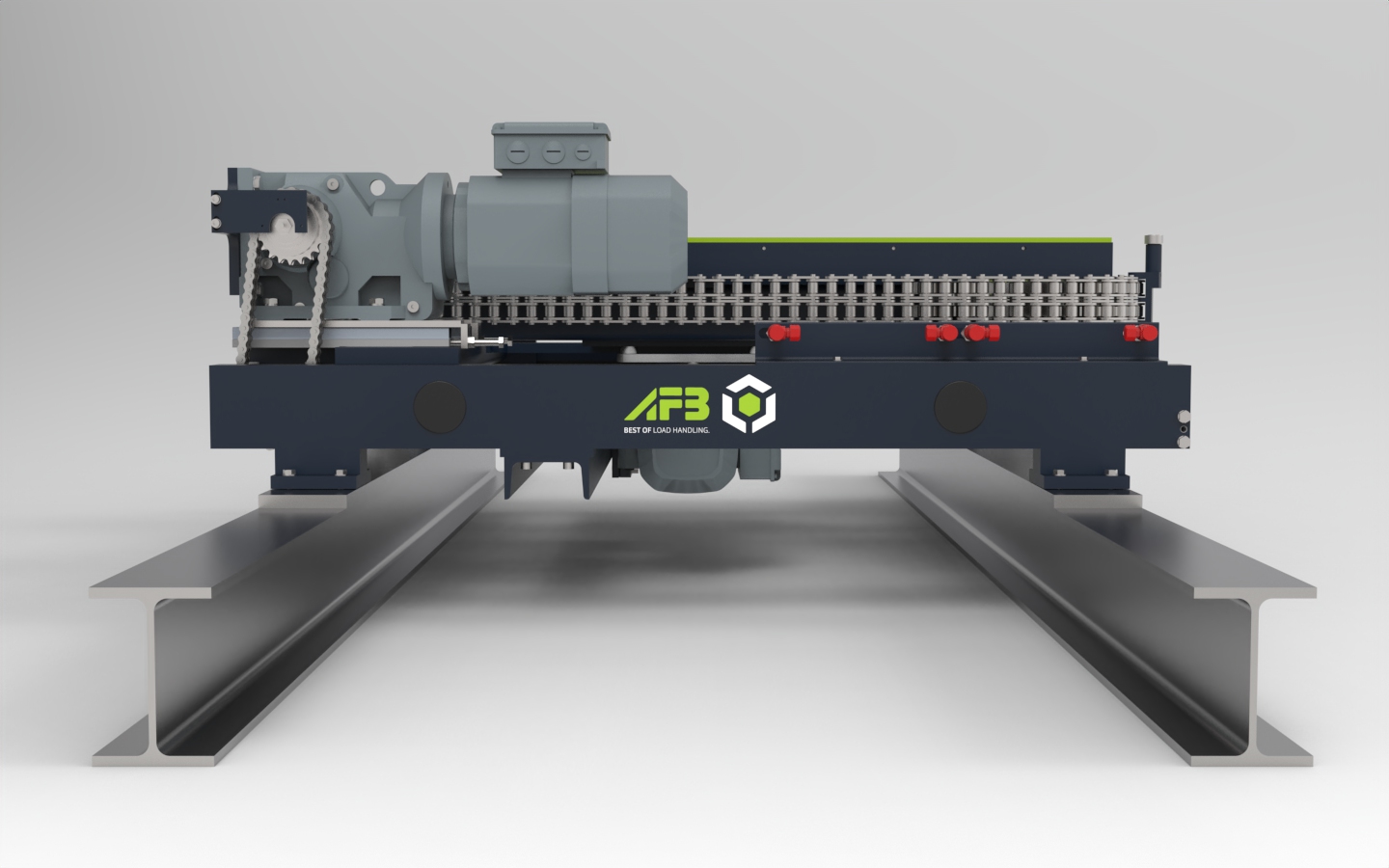

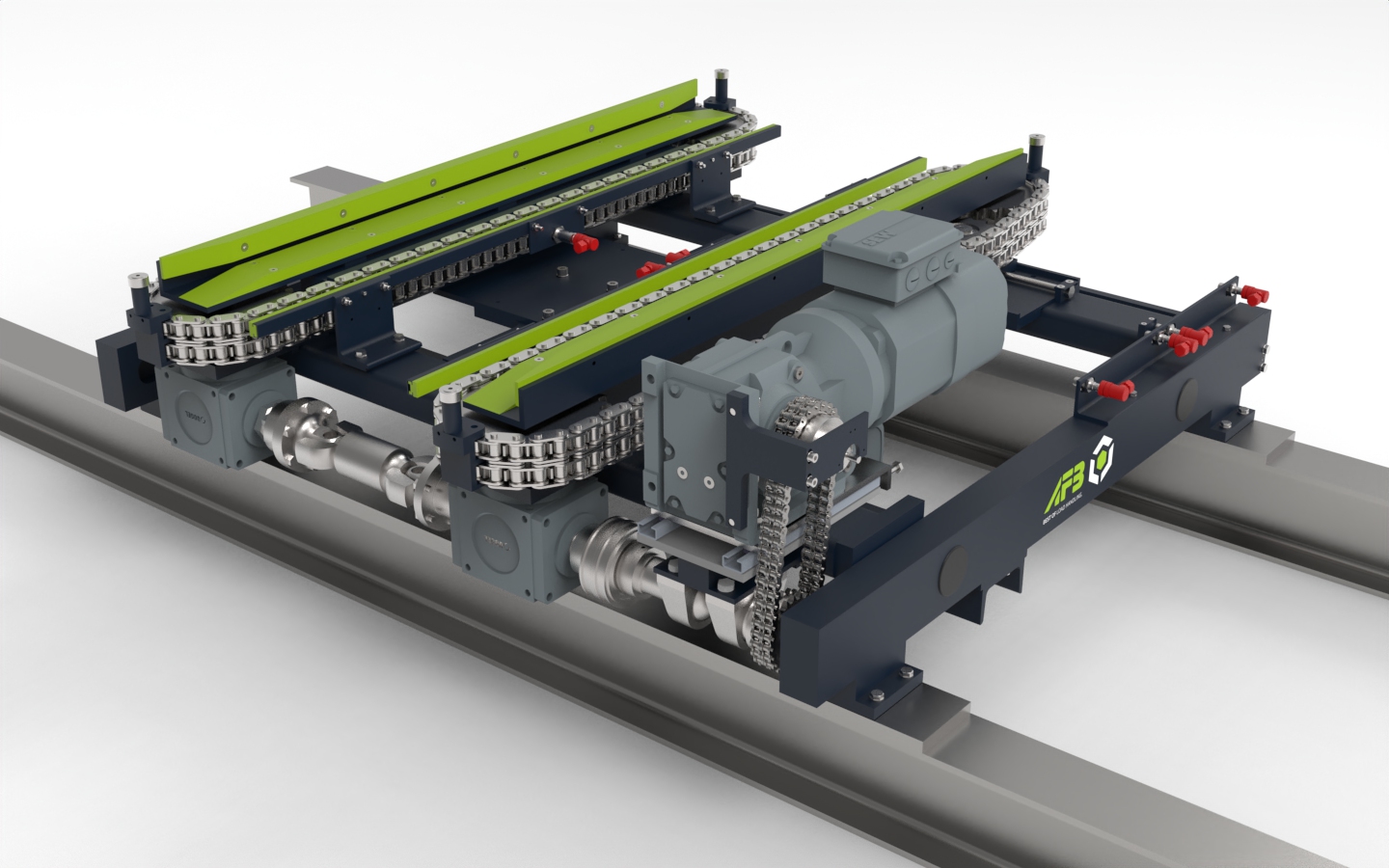

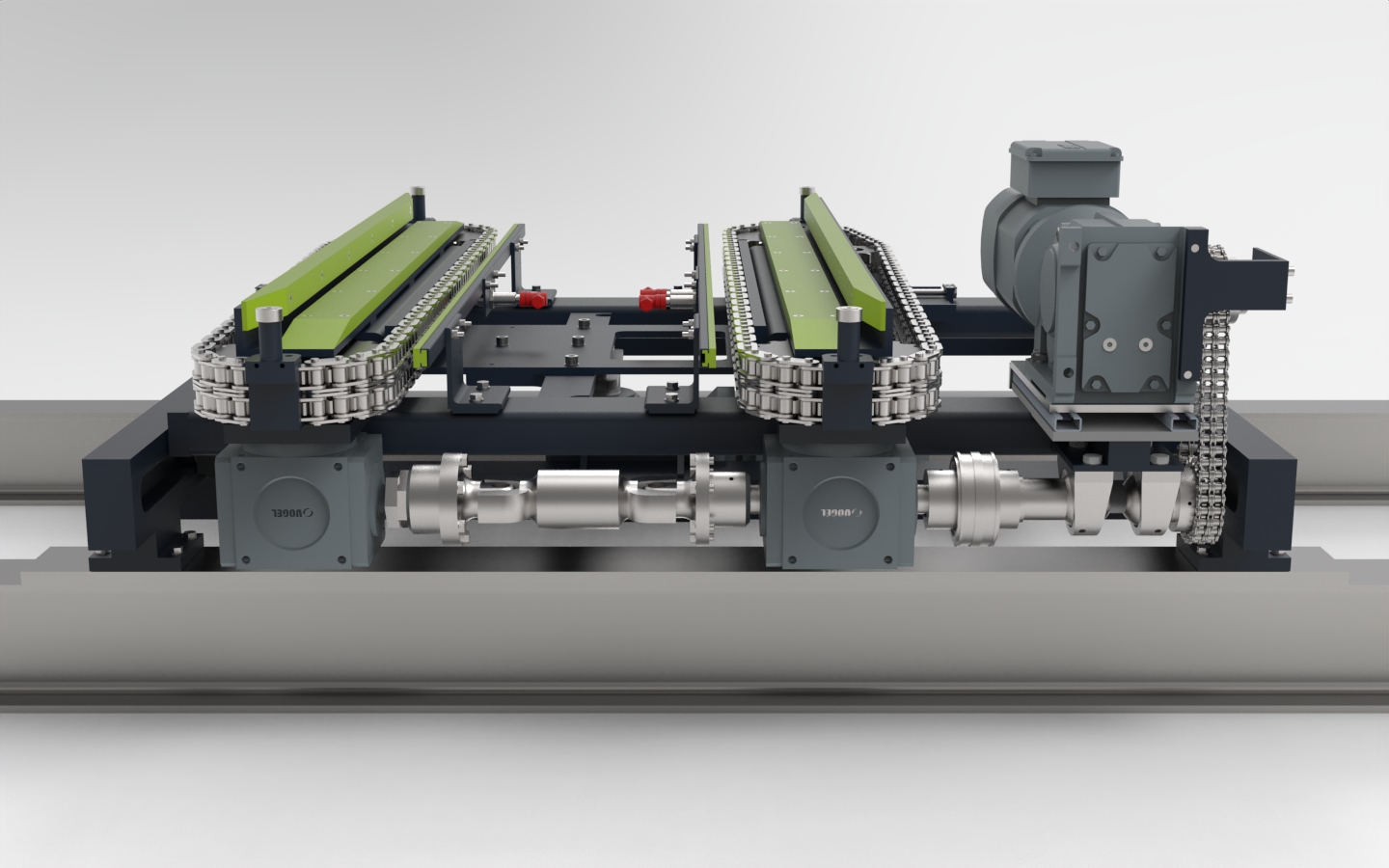

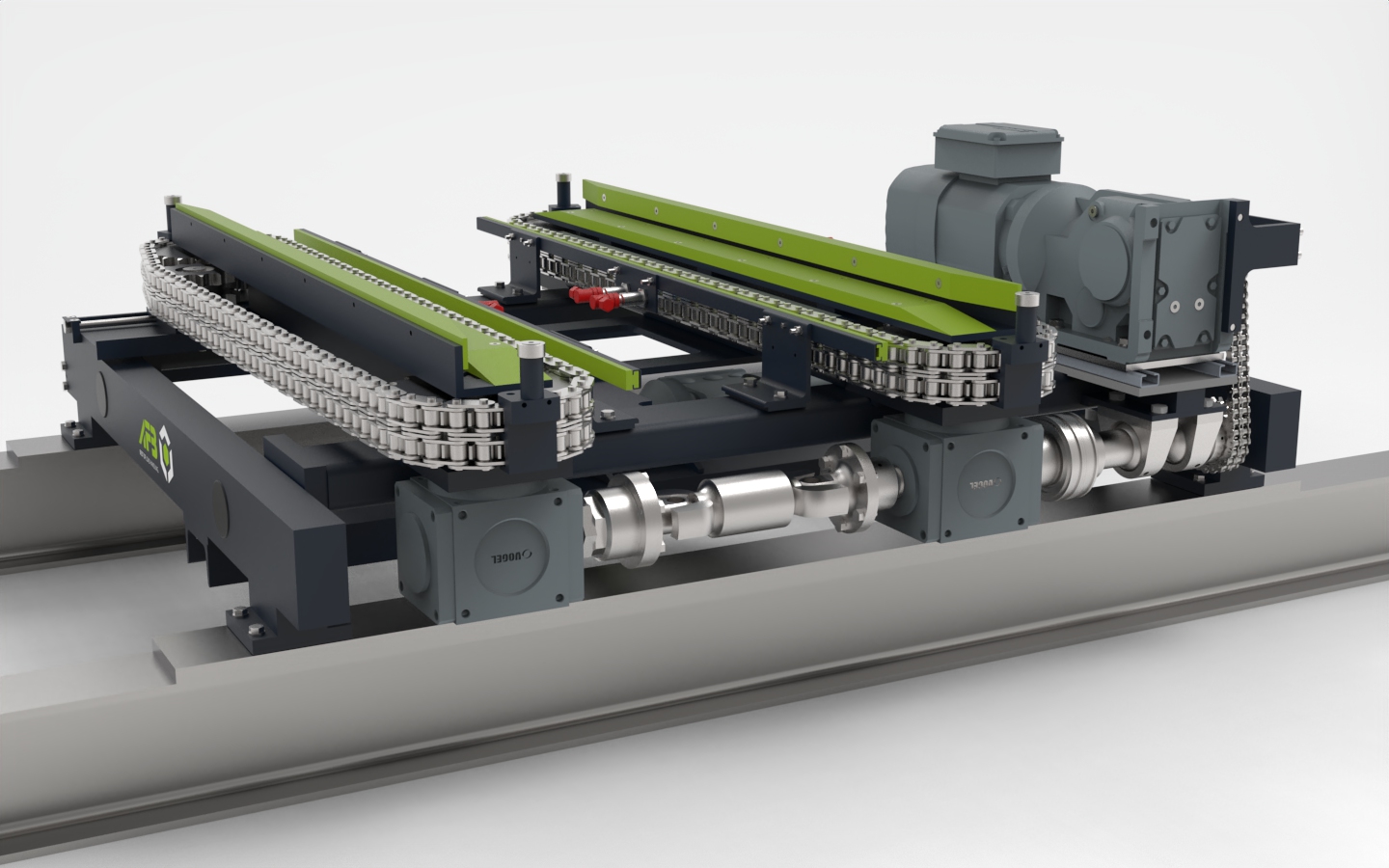

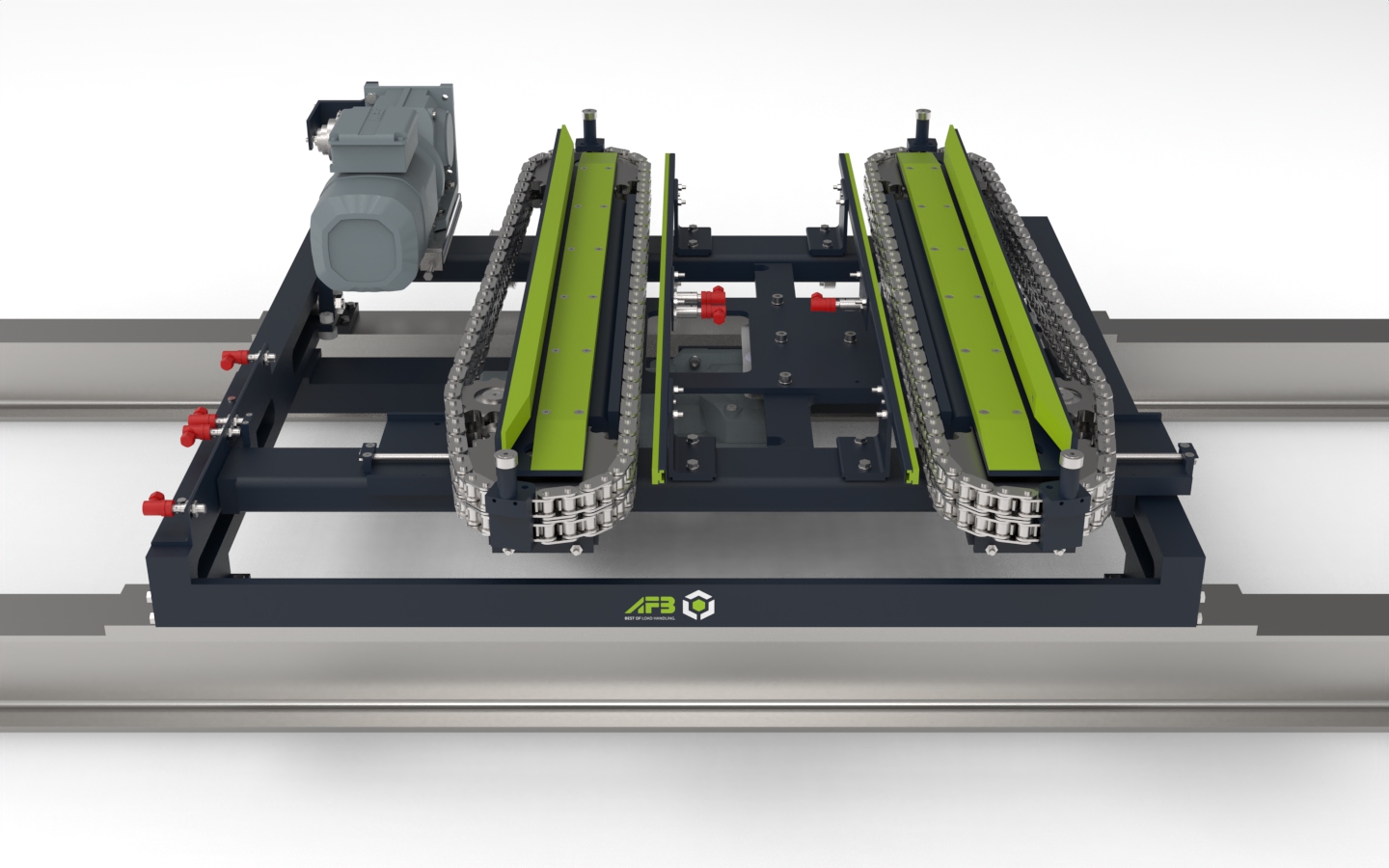

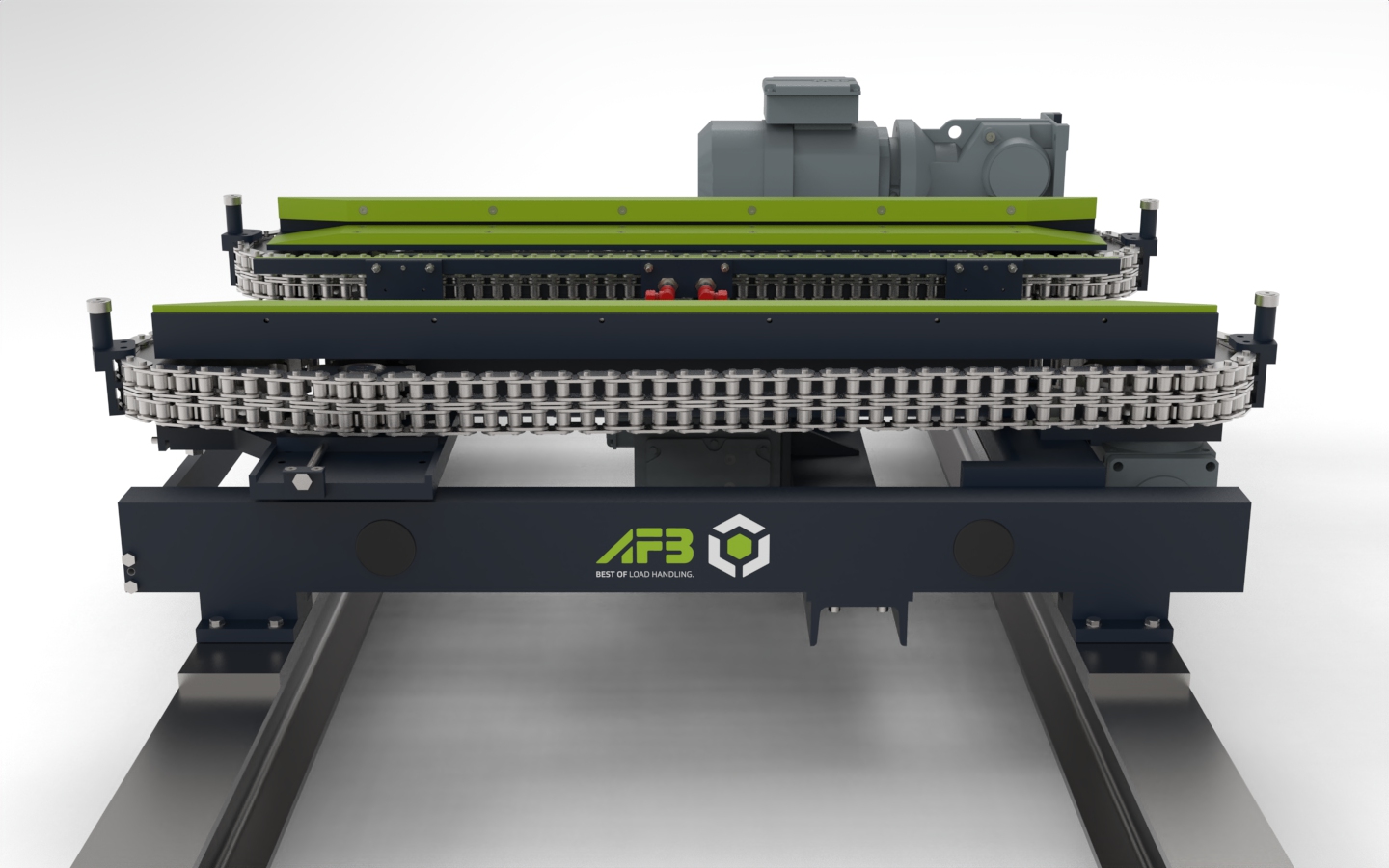

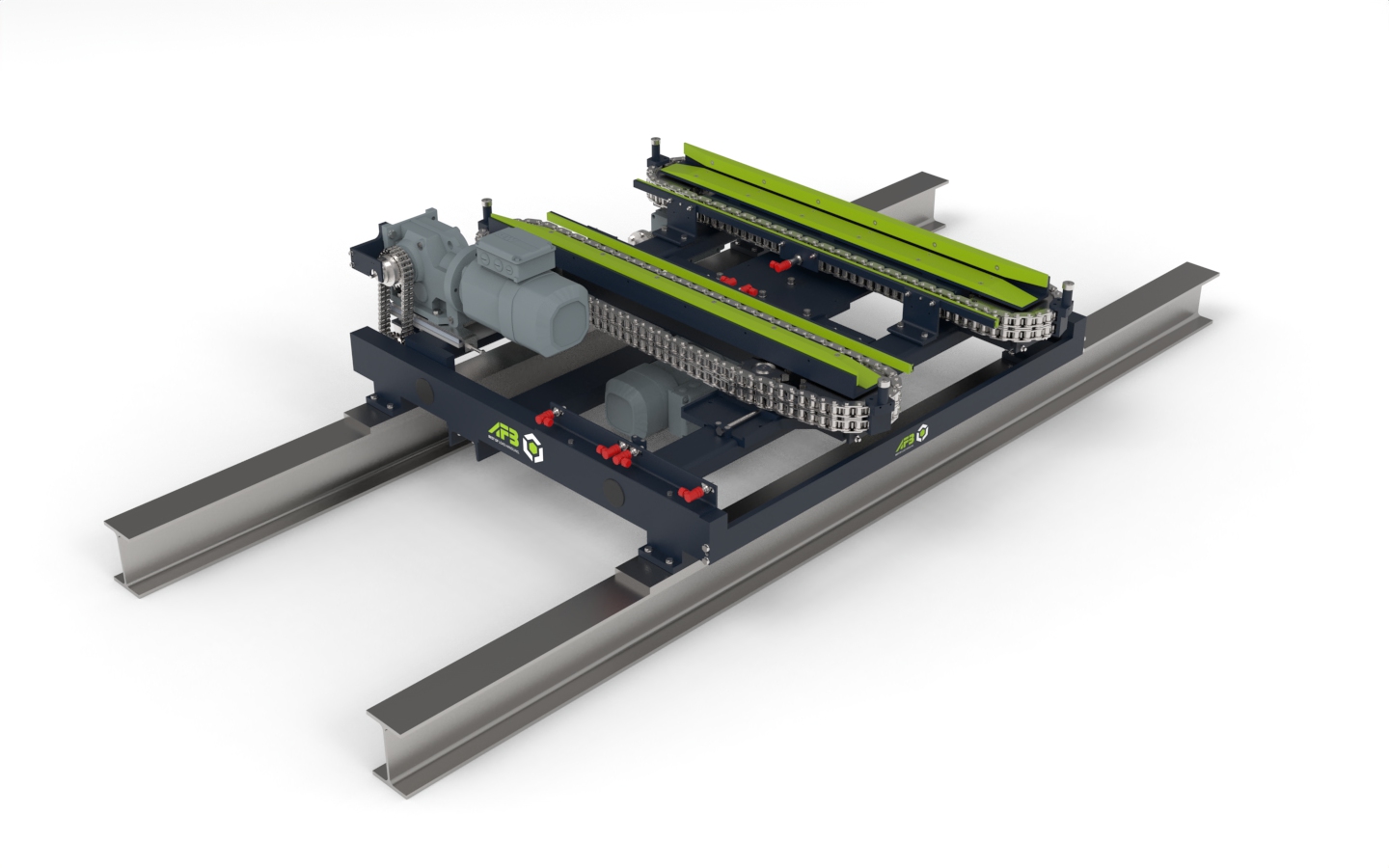

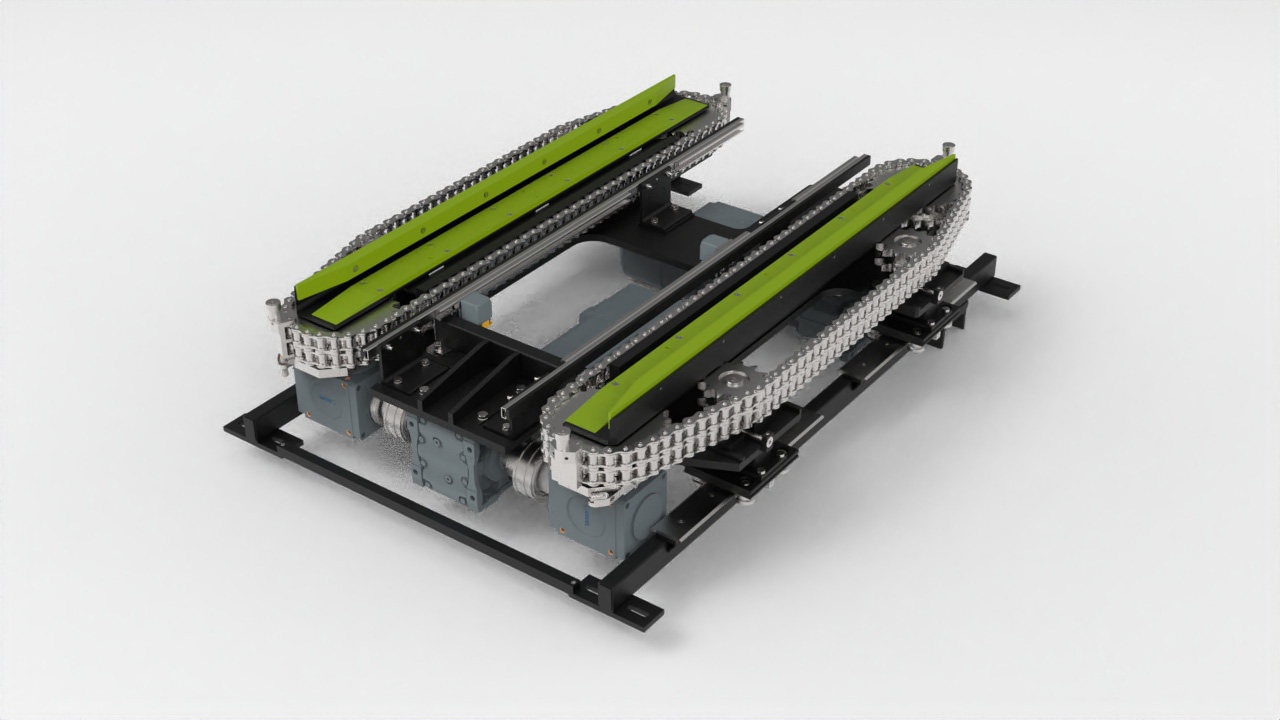

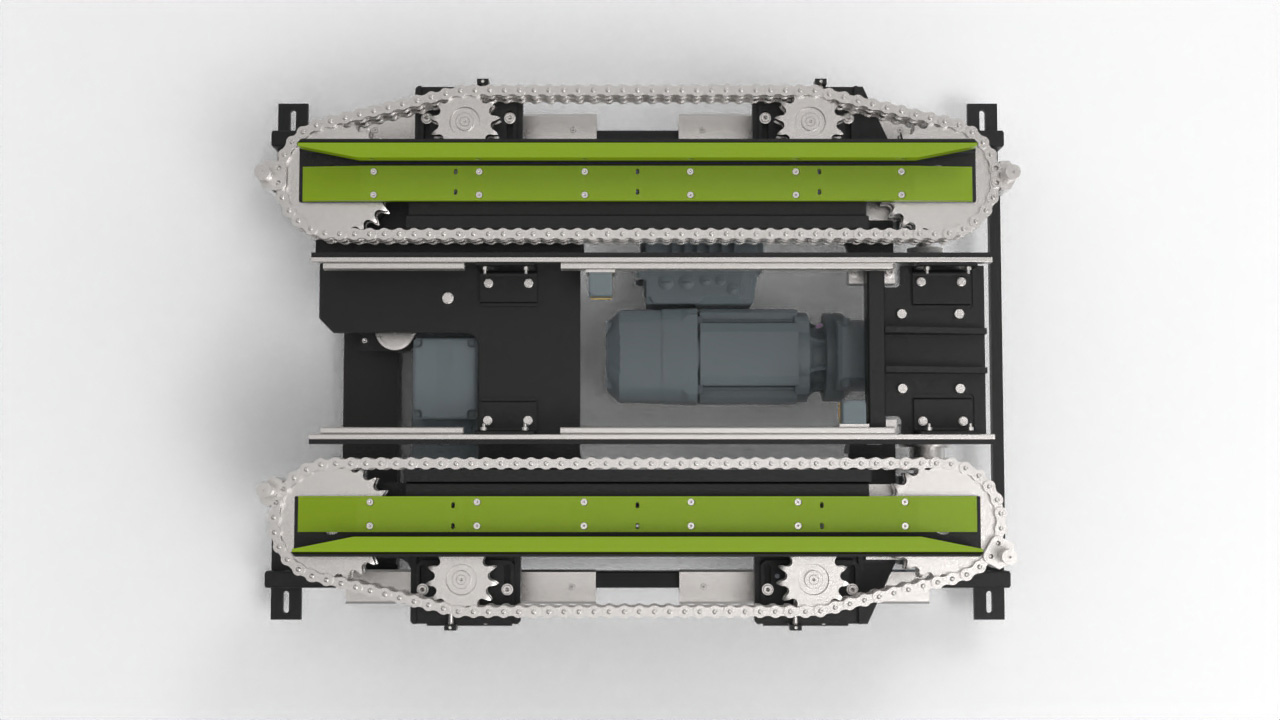

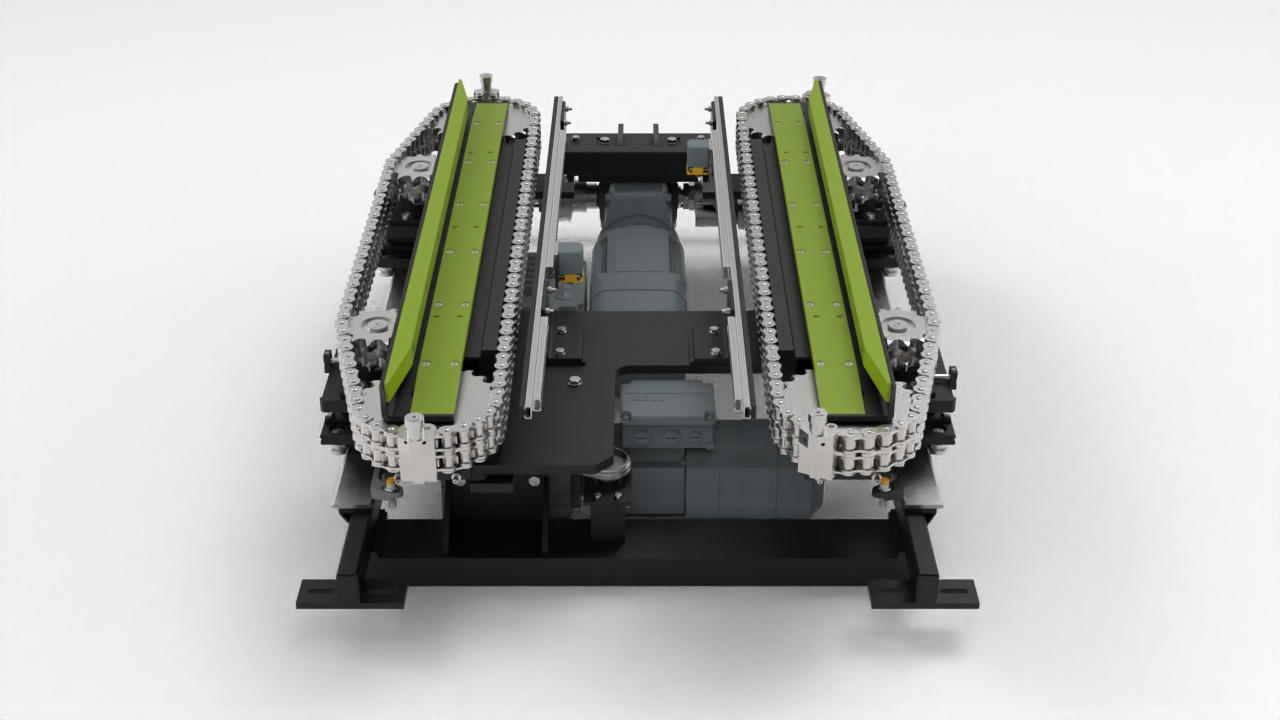

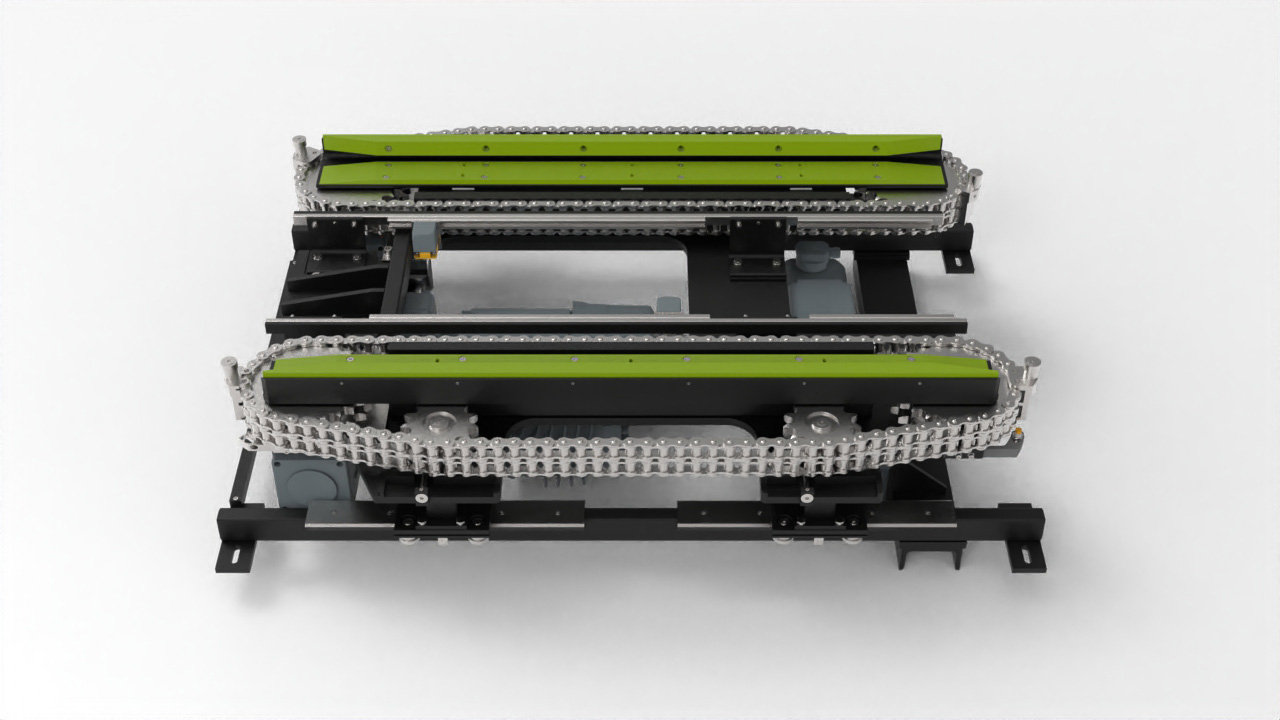

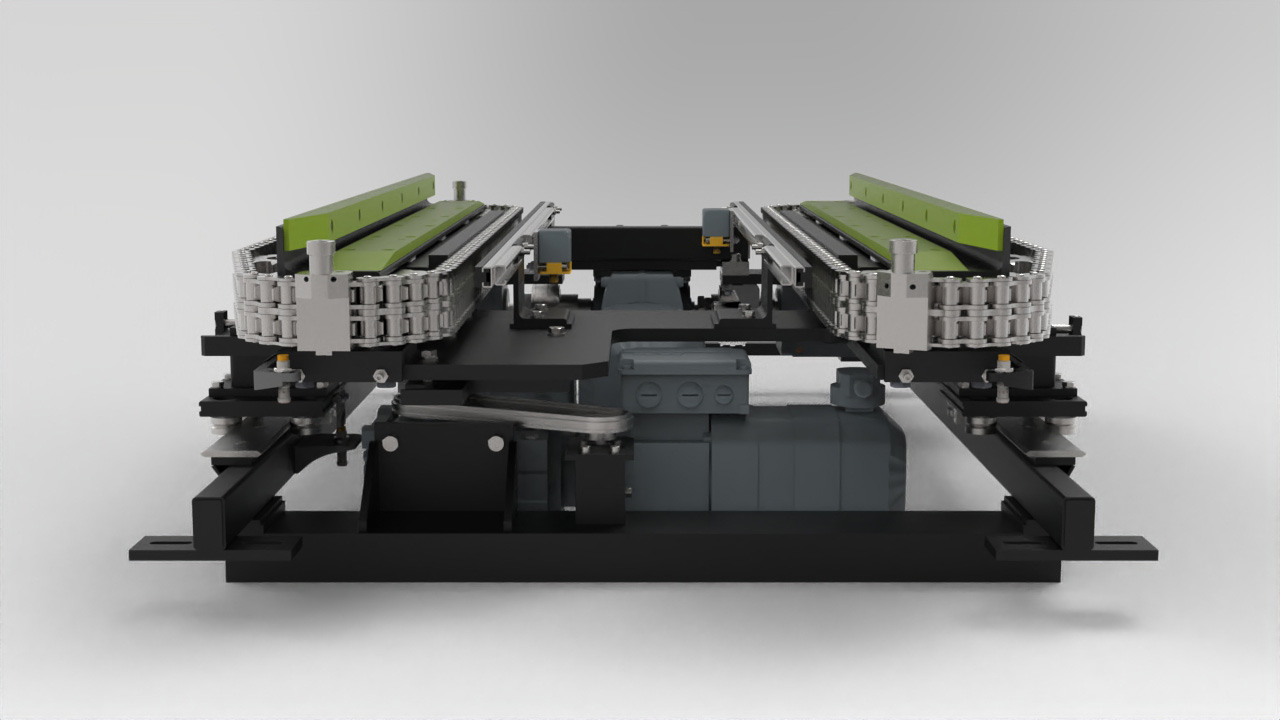

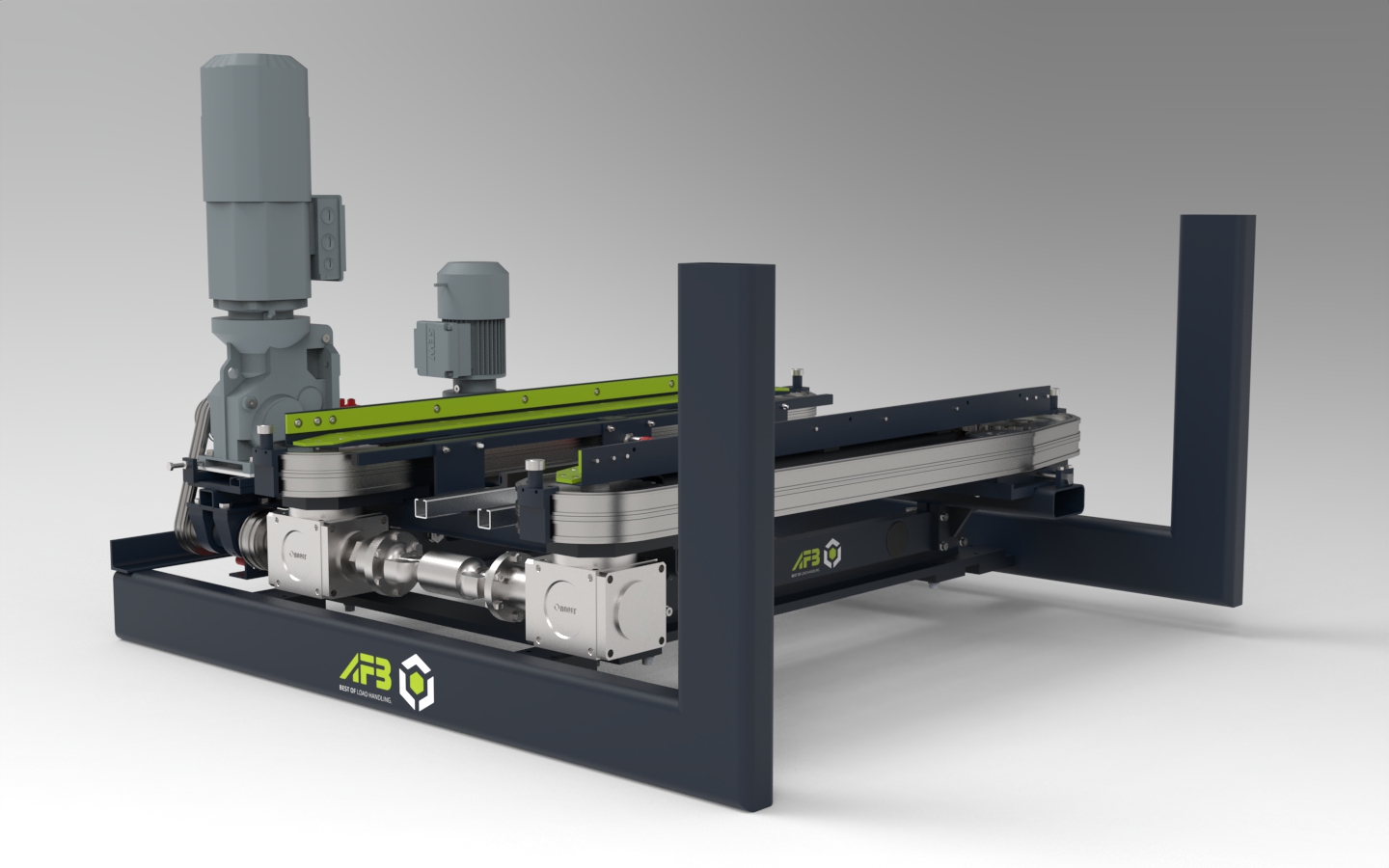

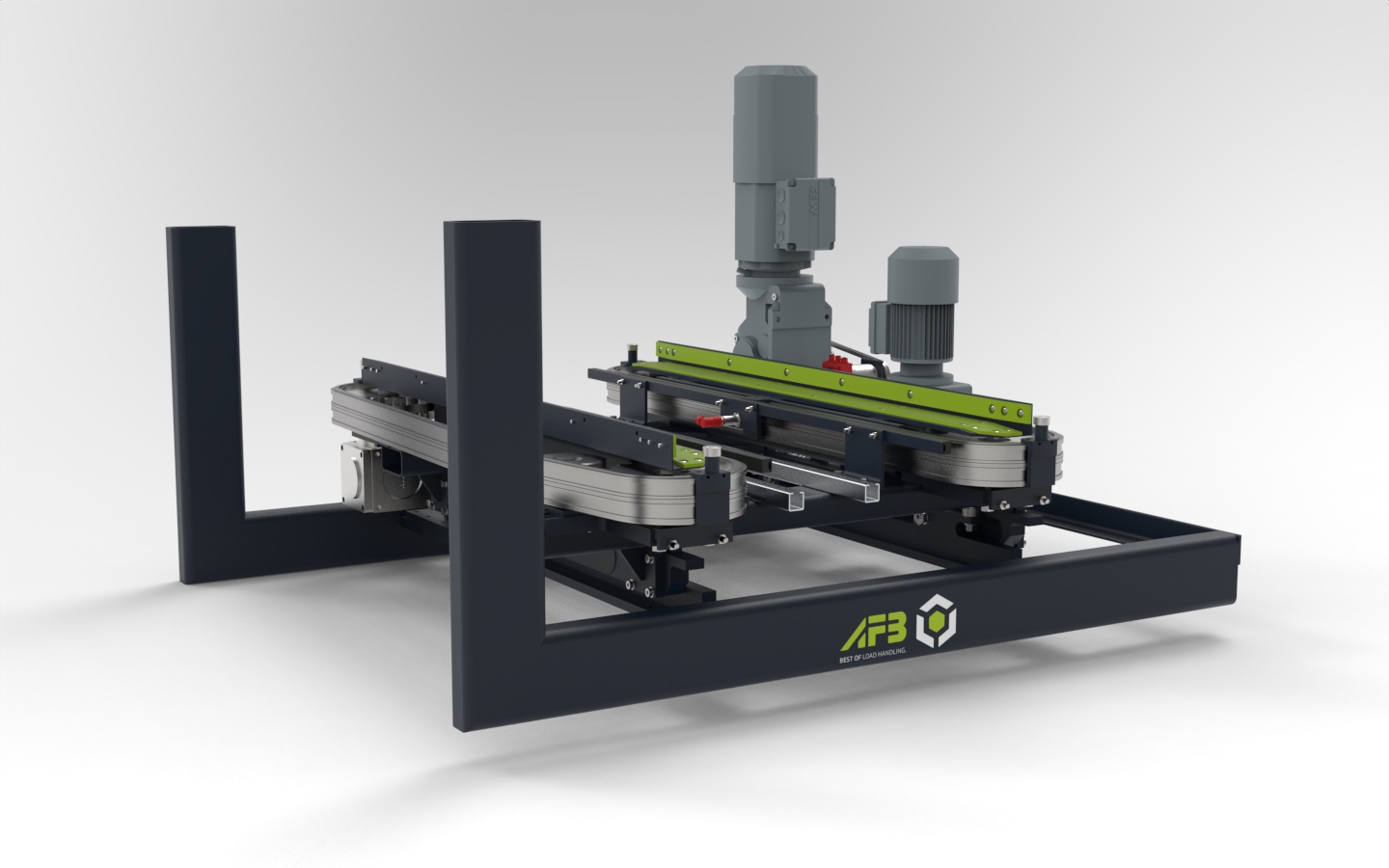

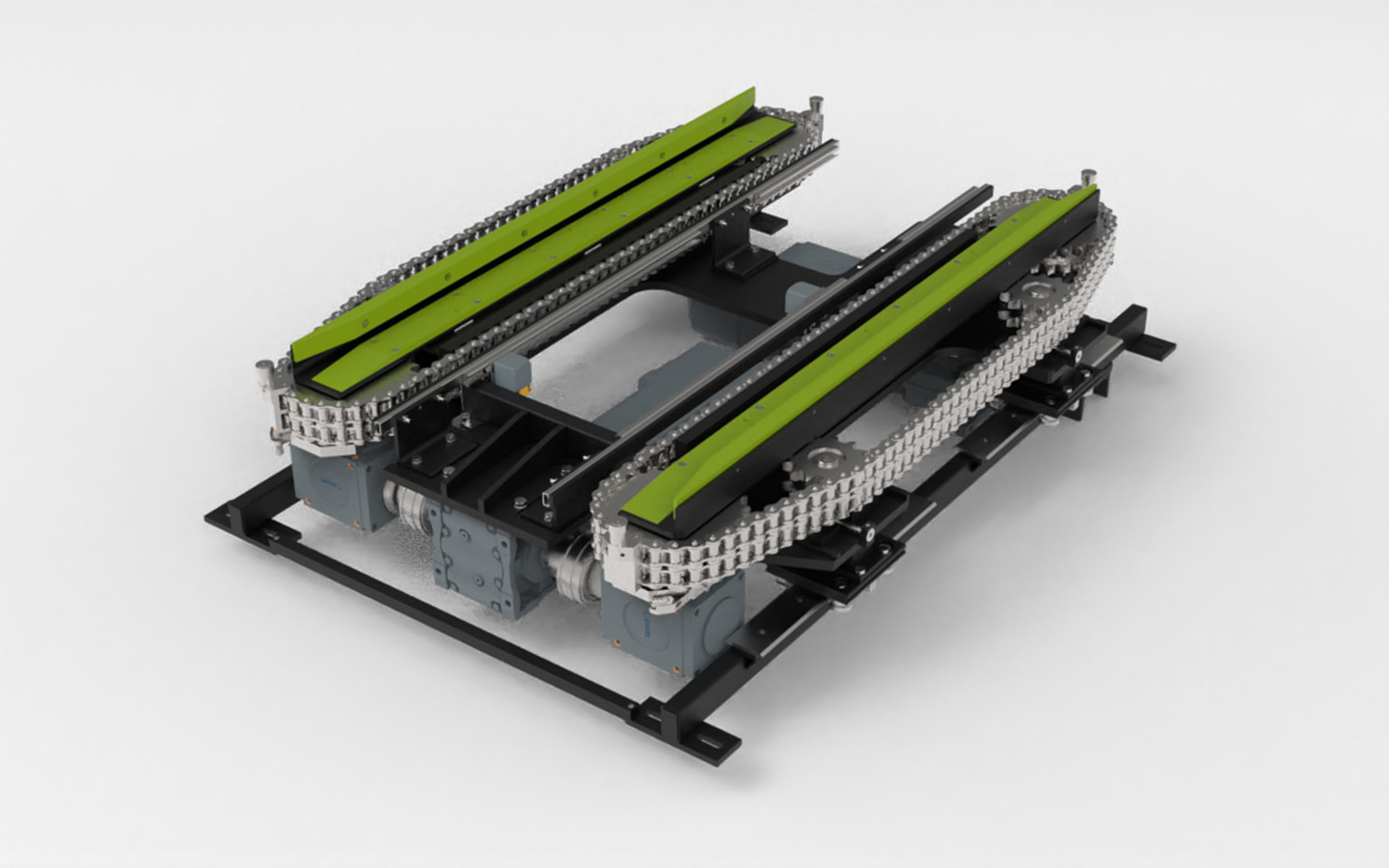

Push-pull system with circulating chain – precise storage and retrieval without lifting

The AFB push-pull system with a circulating chain enables the safe and precise storage and retrieval of trays or crates, eliminating the need for any lifting. The circulating chain ensures smooth movement. The robust and reliable system can be used in both new construction projects and existing applications (retrofit).

Product features

-

Ideal for storing and retrieving loads of up to 350 kg.

-

A circular chain ensures smooth and safe movement.

-

There is no need for the load to be lifted free or for the device to move empty.

-

Integration into existing systems is possible.

-

Can be individually adapted to the application.

Customer benefits

-

Low maintenance and a long service life

-

High reliability thanks to a robust design

-

Spare parts are available throughout the entire life cycle

Industry applications

-

Distribution centres

-

Production automation

-

Spare parts logistics centres

-

E-commerce and omni-channel

-

General merchandise

-

3PL (third-party logistics)

Installed on

-

Storage and retrieval machines

-

Shuttle systems

-

Transfer cars

-

Stationary lifting systems