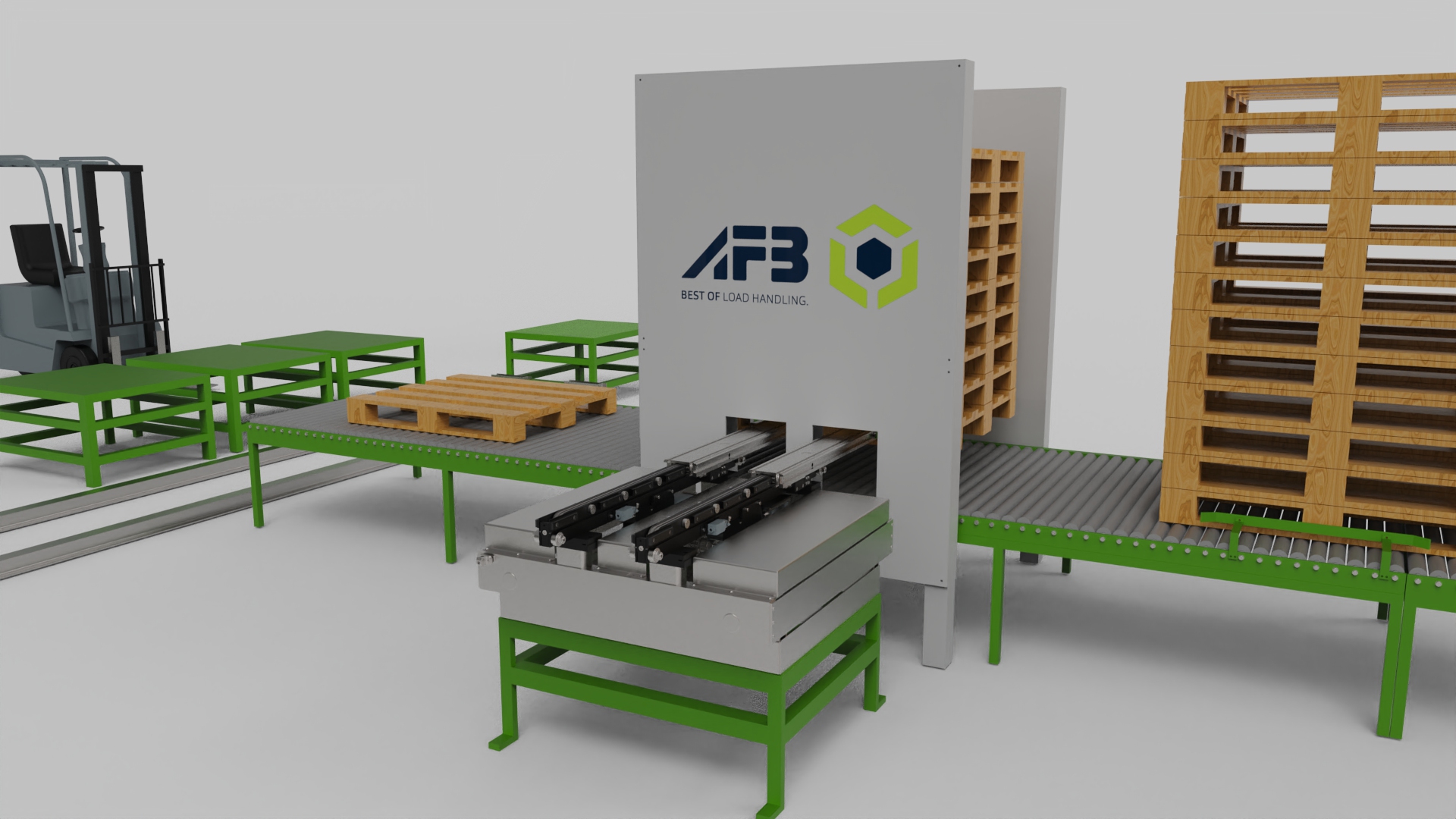

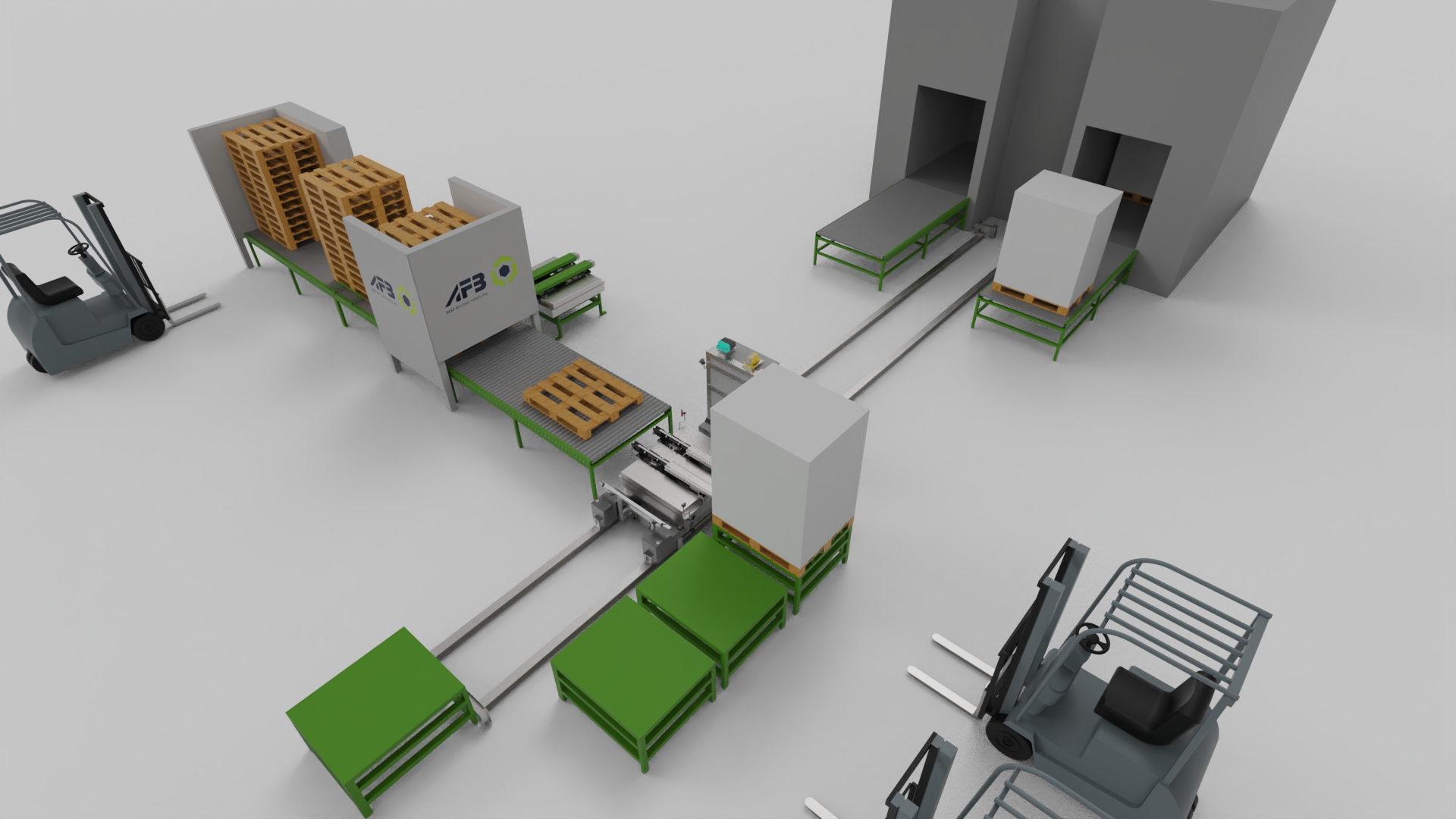

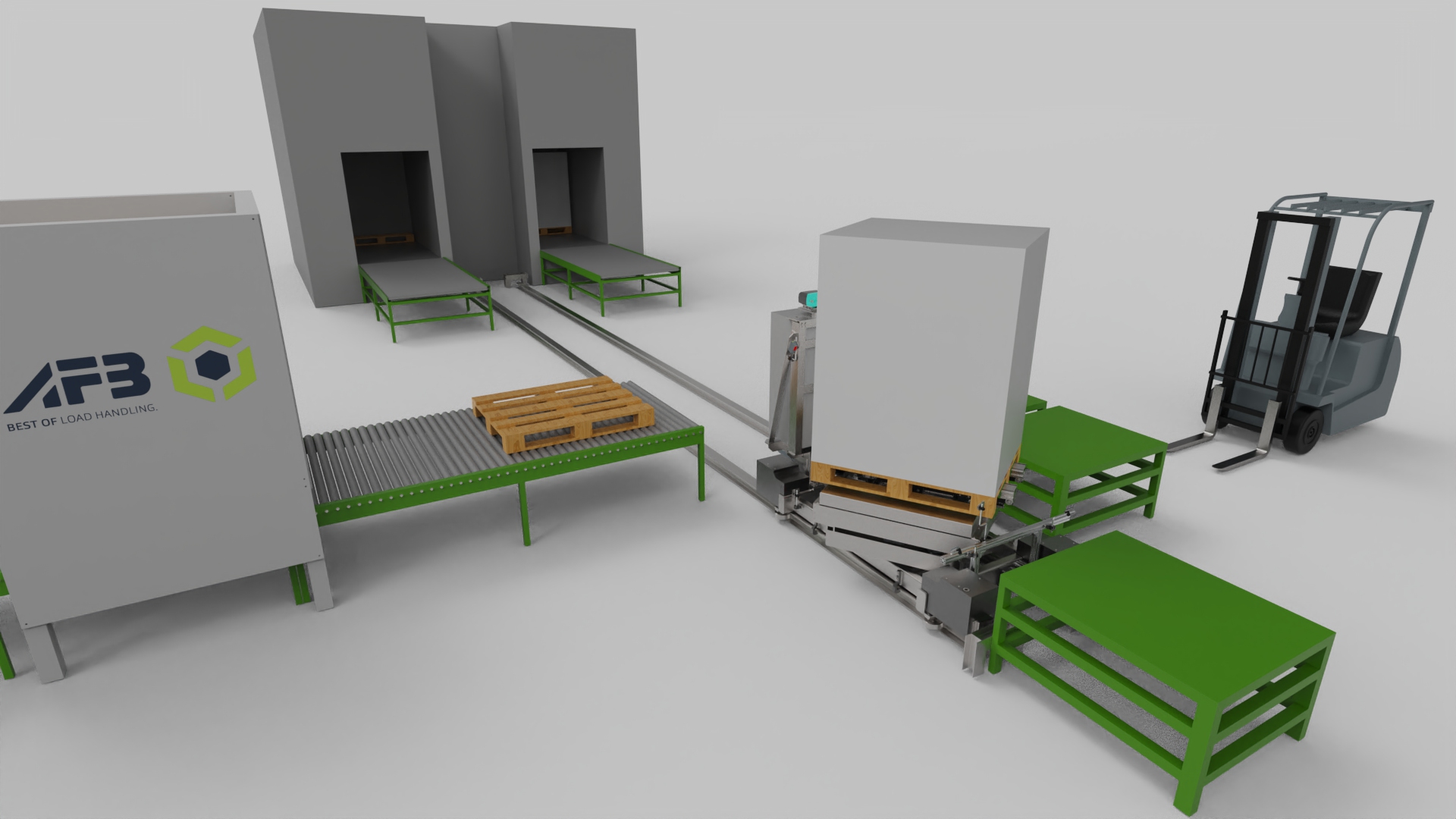

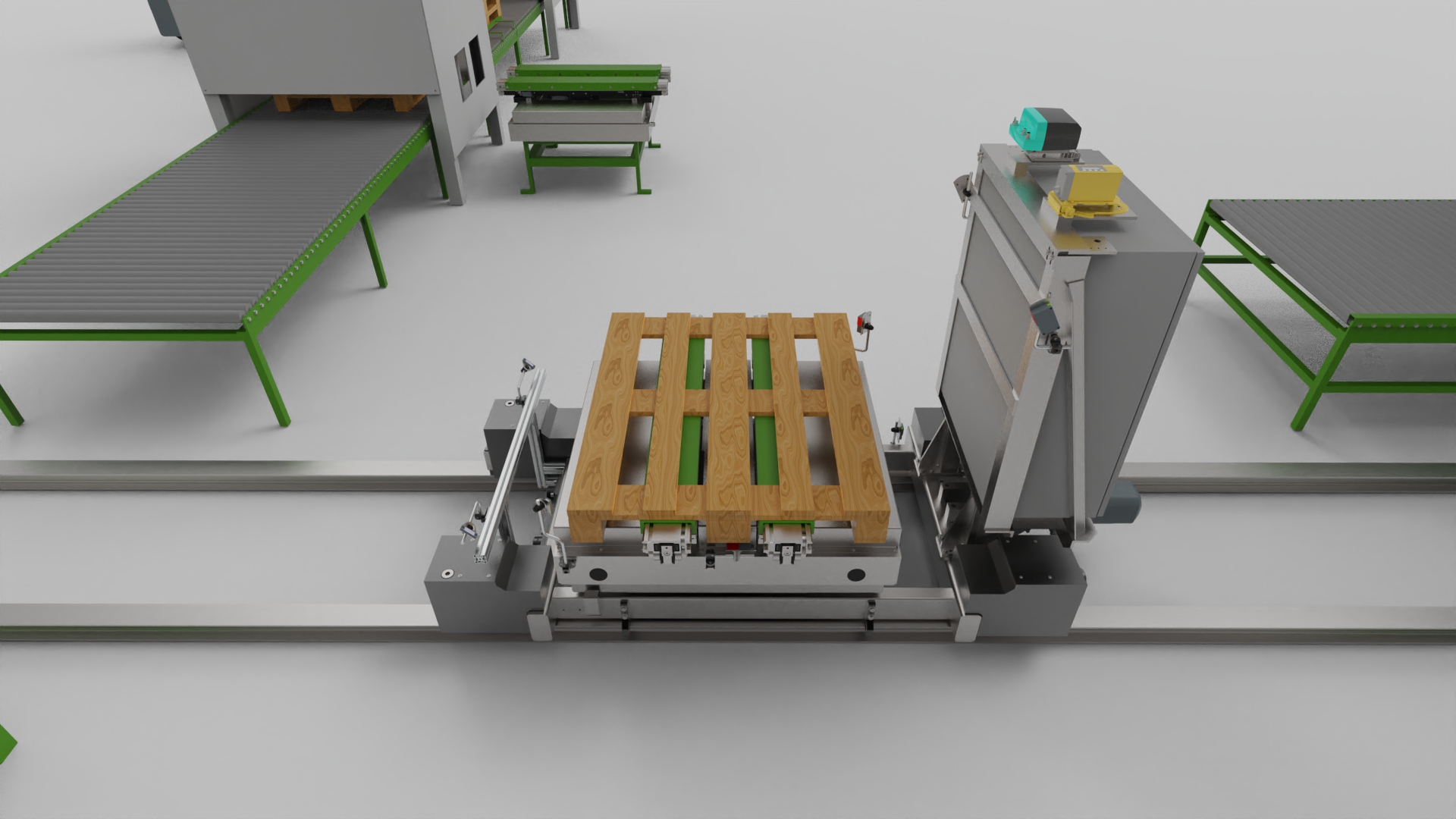

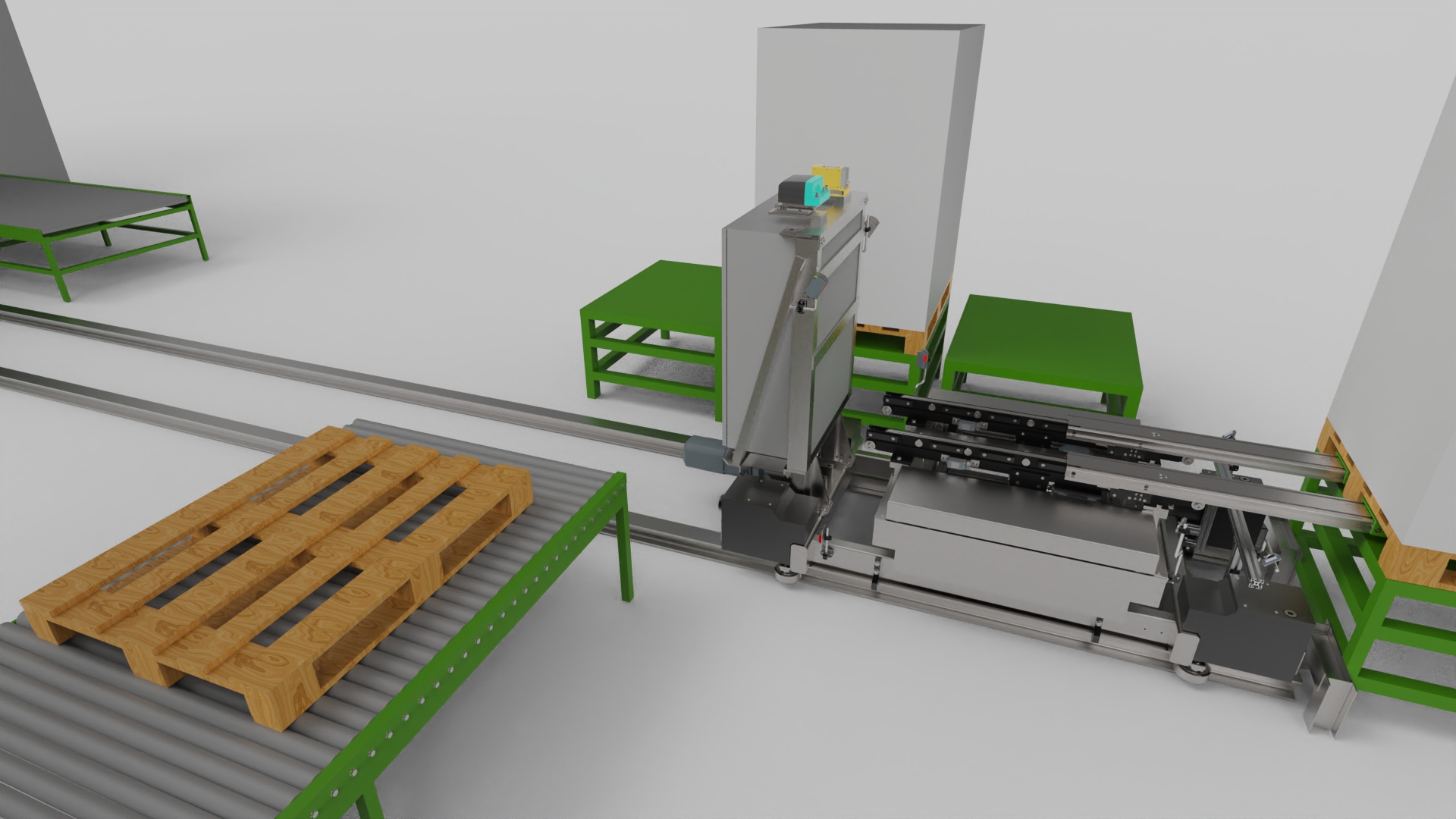

Industry applications – Transfer car

Our latest video shows the integration of our transfer car with rotatable eccentric lifting device and telescopic fork unit into a production isle. The rotatable eccentric lifting device with mounted telescopic fork unit allows the delivery and pick-up position to be operated in a radius of 180 degrees. In this example, pallets are transported to defined storage locations. Separating of pallets is also not a problem – thanks to the combination of eccentric lifting device and telescopic fork unit!