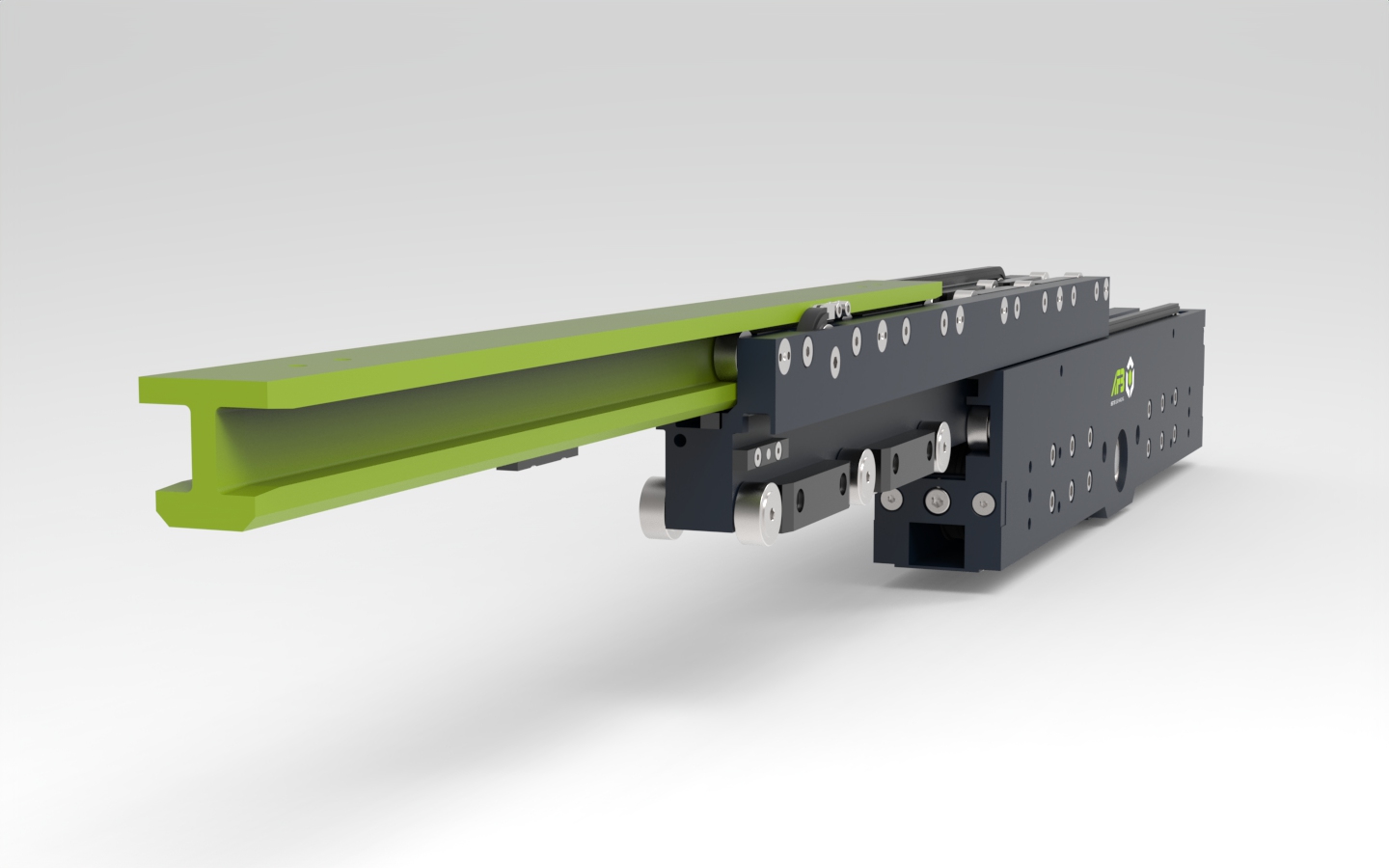

Whether you want to move pallets or coils: By means of the MEDILOAD telescopic fork for single deep storage you will always be able to complete various conveying tasks quickly and dynamically.

- PDF Product Data Sheet Download

Customer benefits

-

Individually adaptable to loading unit and application

-

Highest product reliability thanks to sturdy design

-

Guaranteed spare parts availability for the whole product life cycle

-

Lower maintenance costs/less maintenance

-

Modular and compact design (can be combined with other AFB products)

-

Energy efficient

-

Insusceptible to dirt

Industry applications

-

Automatic high-bay storage systems

-

Distribution centers

-

Production automation

-

Spare Parts Logistics

-

General merchandise

-

3PL (Third Party Logistics Provider)

Installed on

-

Stacker cranes

-

Shuttle systems

-

Transfer cars

-

Stationary transfer stations

-

Attachment devices on industrial trucks

-

Automated guided vehicles

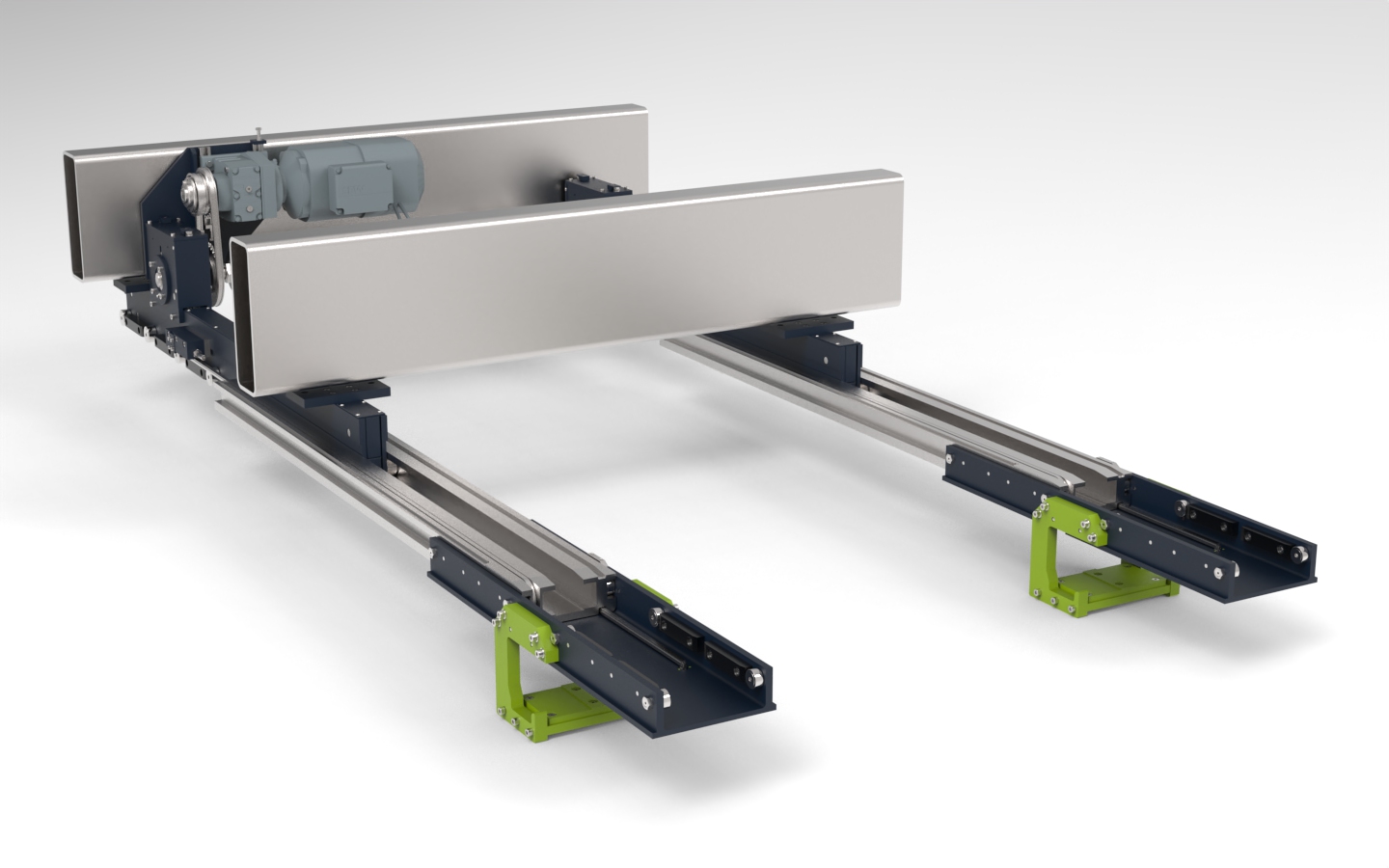

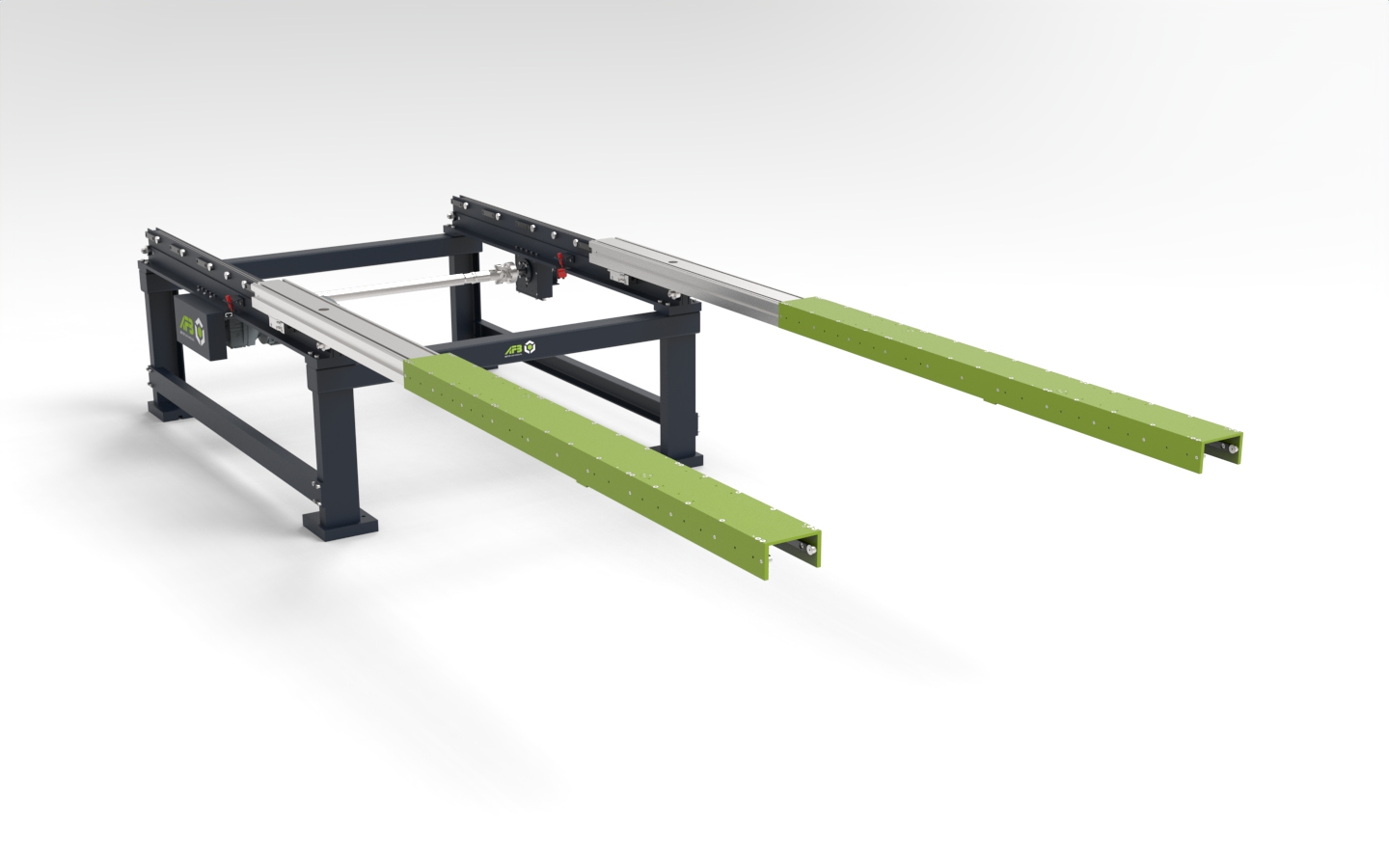

Mediload single deep from AFB

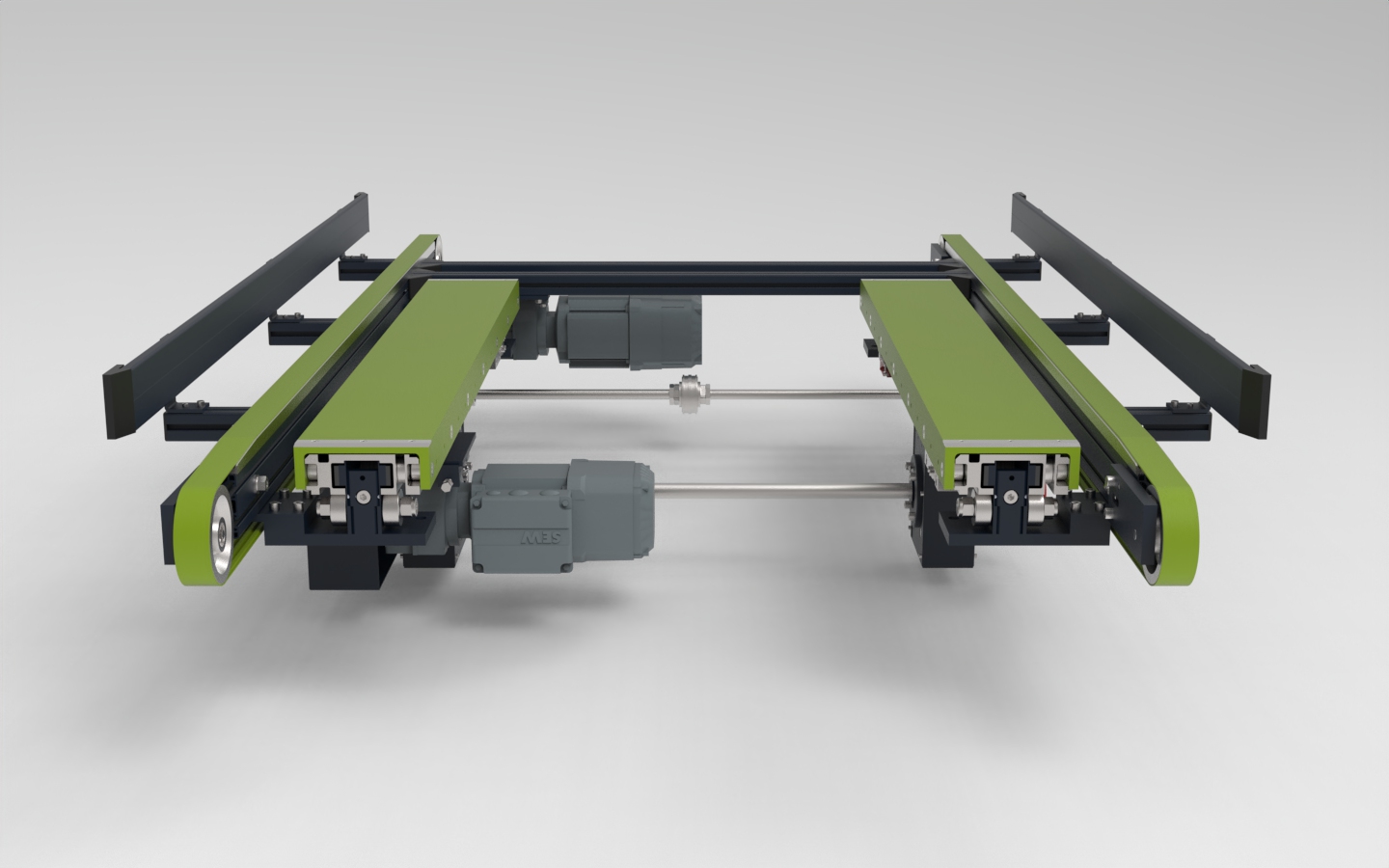

MEDILOAD single deep is available in more than 150 design versions with different extendible cross sections. Ideal for saving space and the chain drive makes it especially efficient. It is excellently suited for cold storage applications down to -40 °C, as well as for high temperature- or applications for the food industries. The drive unit and the fastening options can be positioned flexibly. In addition, a large selection of matching mounting consoles is available, for example for the sensors.

The MEDILOAD single deep can be equipped with additional AFB components: an eccentric lift with chain conveyor, receptacles for special load carriers (e.g. skids and machine pallets), a tilt unit, a rotating unit, an anti-slip coating, symmetrical and asymmetrical prong adjustment and many more. You can also choose whether you would like to combine one, two or multiple prongs.

-

The telescopic fork with a chain drive has a higher total height, because it needs a gearbox.

-

The telescopic fork with a chain is limited to a speed of max. 120 m/min.

-

The self weight is higher of a telescopic fork with chain drive.

-

The belt has no elongation instead of the chain.

-

In cold storage applications

-

In aggressive environments

The MEDILOAD single-deep telescopic forks are also available in a hanging fork configuration and can be ordered with custom accessories according to the needs of your specific application.

Our Mediload single deep devices in action

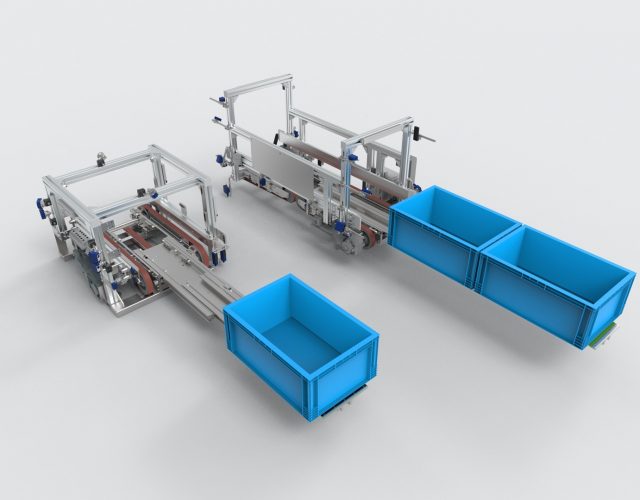

Efficient Oven Loading with Telescopic Fork and Belt Conveyor

For the automated loading and unloading of an industrial oven, our customer uses the telescopic fork F-60-166-HK-1250 with an integrated belt conveyor.

Efficient goods handling with our telescopic fork on a rotating unit

The modernisation of an automatic high-bay warehouse places high demands on performance and availability. A central component of this optimisation is the use of a telescopic fork including a rotating unit D-60-166-HK-1400.

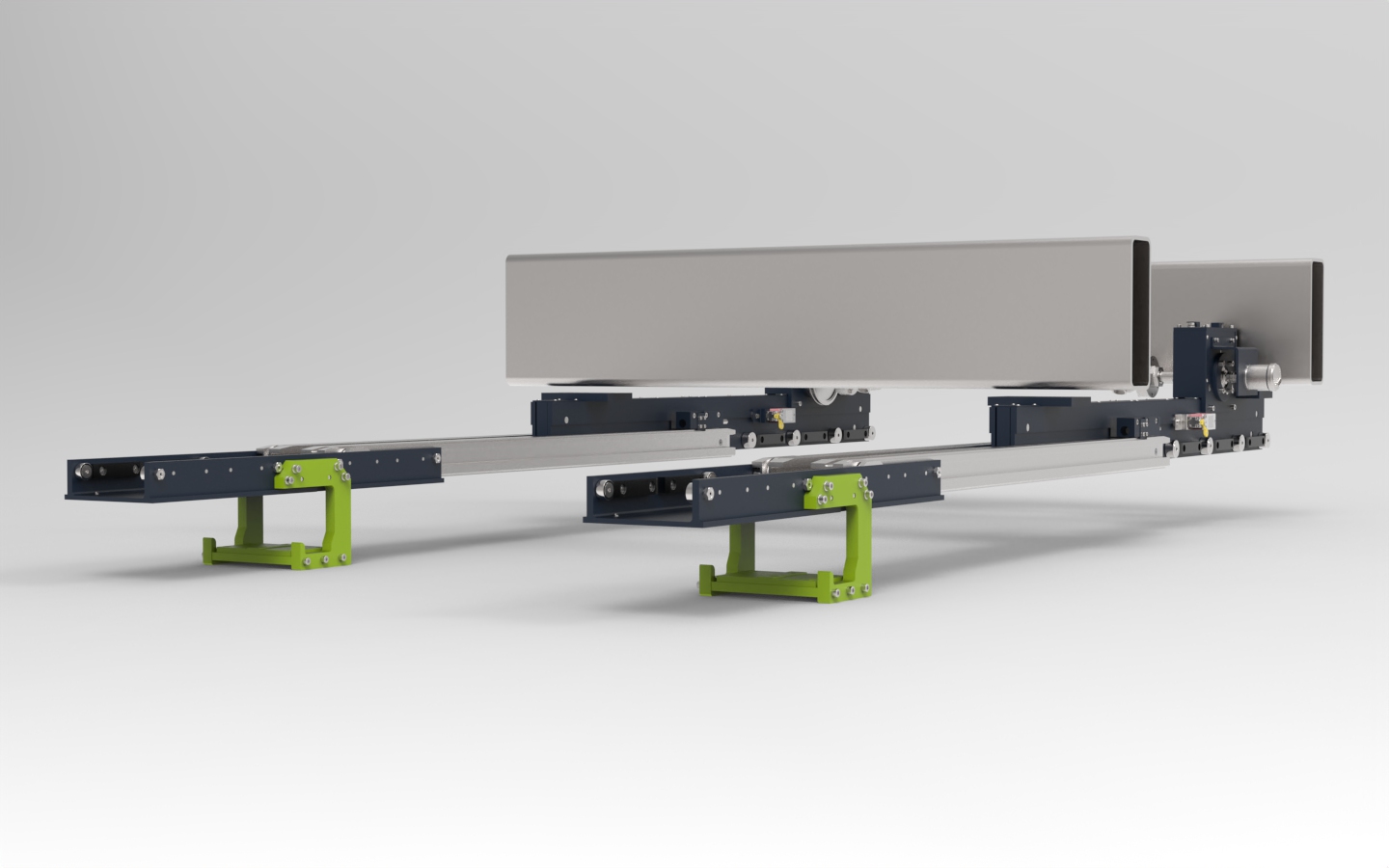

Space-saving solution with the 124-81-780 Telescopic fork unit

For a manufacturer of saws and storage technology in the field of long metal products and sheet metal storage, efficient use of space is a critical factor.

Customised for your long goods storage

The Telescopic fork 142-162-1050 was developed to meet the specific requirements of our customer. Our custom design can be tailored to your specific needs, optimizing storage space and facilitating the handling of long goods.

Successful implementation of the retrofit at the car manufacturer

Retrofit offers our customers the possibility to improve their existing systems with the help of different strategies. AFB sucesfully replaced an existing telescopic fork from a competitor in the existing installation of an automobile manufacturer.

Telescopic fork for the steel industry

In the production of steel strips, test pieces have to be removed regularly. This process has to be done in a safe way without endangering people.

Cross telescopic fork for tire storage

AFB offers special cross-telescopic forks for single or double deep storage of green tires or finished tires. Due to its compact design, it has a particularly narrow extending cross-section.

Special telescopic fork for the transport of wooden board packages

We have developed a particularly flat and at the same time strong special telescopic fork for transporting packages of wooden boards of various sizes, which is used on an industrial truck in semi-automatic operation.

Telescopic fork with asymmetric prong adjustment

Telescopic fork with asymmetrical prong adjustment for a center line center line distance of the prongs from 390 mm to 990 mm to pick up different pallet sizes.

Telescopic fork for storing painted car bodies

Developed for the production line of a German premium car manufacturer, the telescopic fork type 150-420-5100 meets the highest reliability standards.

Hanging telescopic fork with supports for cradles

A hanging version of a telescopic fork which is transporting frames into a coating device.

Telescopic fork prepared for prong adjustment

A telescopic fork prepared for a prong adjustment.

Hanging telescopic fork with supports

Hanging telescopic fork that is used for transporting and storing rolls of prematerial in the tire manufacture industry.

Customized Telescopic Fork Solution for Car Body Transport

We developed a telescopic fork unit 105-174-HK-G-2100, for a leading automobile manufacturer, which is precisely configured to fit the requirements of the production line.

Customized Telescopic Fork Unit for the Wood Industry

We developed a V-F-60-166-HK-1400 telescopic fork unit with four prongs for a system integrator, specially tailored to the requirements of an end customer in the woodworking industry.