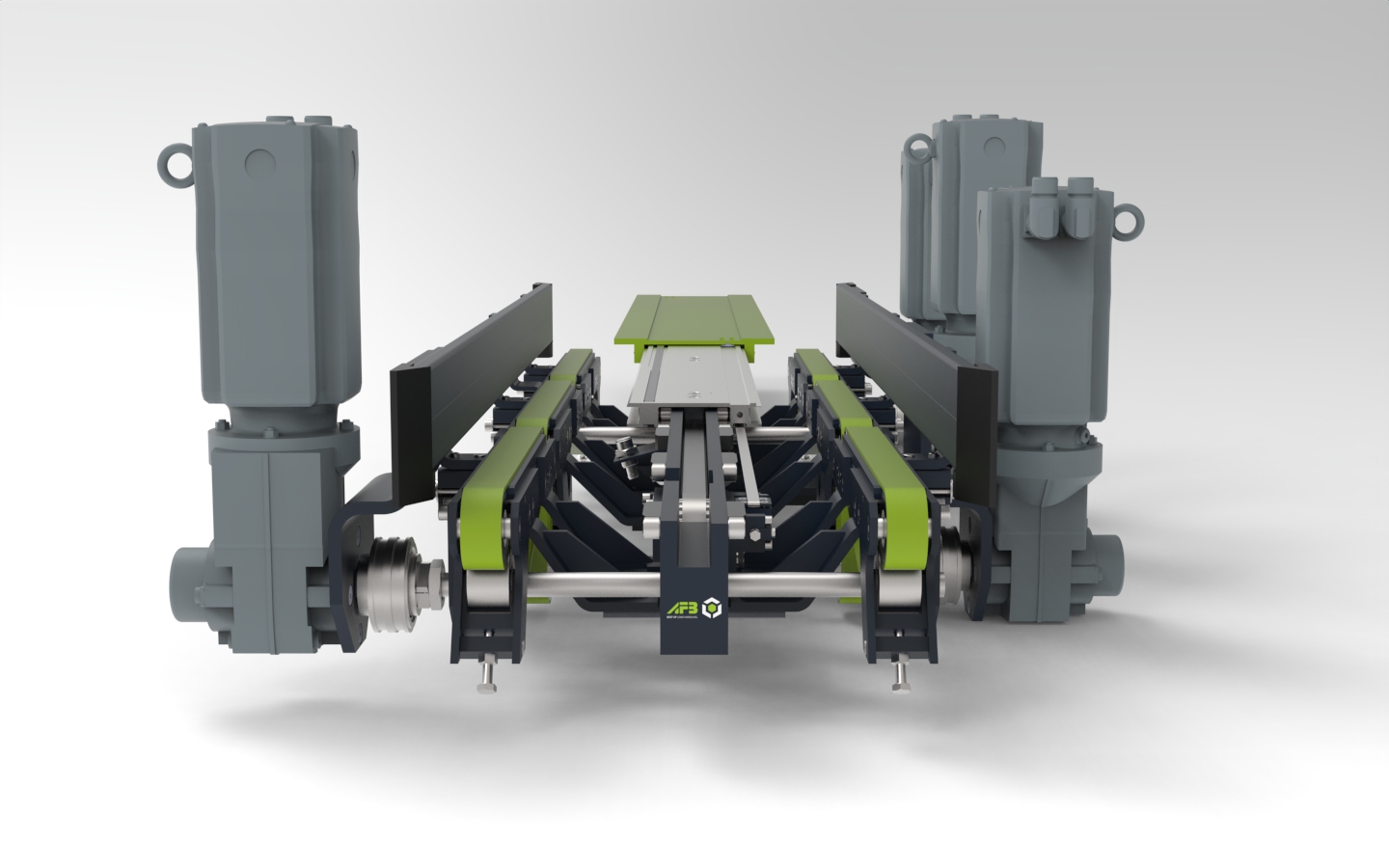

Compact and flexible: the MINILOAD telescopic fork units from AFB are the perfect lifting devices for automated warehouses dealing with loads of up to 150kg.

The MINILOAD telescopic forks are available in both single-deep and multi-deep configurations.

- Product data sheet download

Product features

-

Ideal for loads up to 150 kg per fork

-

Compact and solid aluminium construction

-

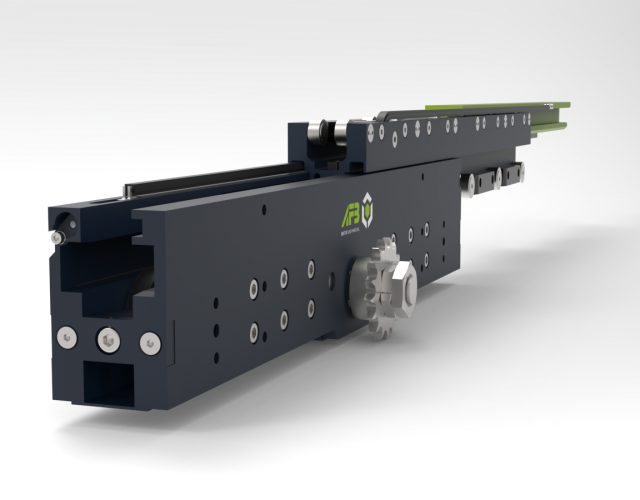

Entirely belt-driven or chain driven

-

Lightweight

-

Optionally equipped with belt conveyors for collecting multiple loads

-

Minimal extension width at optimized heights

-

Flexible positioning possible

-

Matching accessories available (e. g. for sensor systems etc.)

-

Speeds up to 2m/s

-

Acceleration up to 5m/s2

Customer benefits

-

Individually adjustable to different load units and application purposes

-

Solid design ensures extreme reliability

-

Guaranteed availability of spare parts for the product’s entire life cycle

-

Low maintenance costs

-

Modular and compact design (can be used in combination with other AFB products)

-

Energy efficient

-

Highly dirt resistant

Industry applications

-

Distribution centers

-

Production automation

-

Parts logistic centers

-

E-commerce & omi-channel

-

General merchandise

-

3PL (Third Party Logistics)

Installed on

-

Stacker cranes

-

Shuttle systems

-

Transfer cars

-

Implemented stationary units

-

AGVs

Miniload from AFB

-

The telescopic fork with a chain drive has a higher total height, because it needs a gearbox.

-

The telescopic fork with a chain is limited to a speed of max. 120 m/min.

-

The self weight is higher of a telescopic fork with chain drive.

-

The belt has no elongation instead of the chain.

In cold storage applications

In aggressive environments

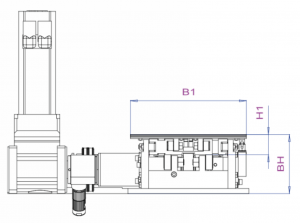

Telescopic Miniload technical specifications

| 32 mm | 38 mm | 40 mm | 40 mm | 42 mm | 52 mm | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type 1 | Type 2 | Type 3 | Type 4 | Type 5 | Type 6 multideep | ||||||

| H1-Height extending cross section | 32 mm | 38 mm | 40 mm | 40 mm | 42 mm | 52 mm | |||||

| B1-Width of extending profiles | min. 155 mm | min. 155 mm | min.155 mm | min.175 mm | min.175 mm | min. 225 mm | |||||

| UT-Fork lenght | 600 / 800 / 850 / 900 / up to 1800 mm | ||||||||||

| BH-Overall height | 107 mm | 113 mm | 115 mm | 117 mm | 119 mm | 138 mm | |||||

| HUB-Stroke | > Under table length | >2x Under-table length | |||||||||

| Aisle width | 700 - 2.000 mm | ||||||||||

| Payload | 100 kg - 250 kg on one prong | 100 kg on one prong | |||||||||

| Acceleration | max. 5 m/s | ||||||||||

| Speed | max. 3 m/s | max. 5 m/s | |||||||||

The Miniload telescopic with attachments can be integrated in: rotating units, lifting units with load centering, support brackets with integrated lifting unit, and much more.

Our Miniload devices in action

Space efficiency with MINILOAD telescopic fork unit

Maximum storage density and efficiency – the MINILOAD telescopic fork unit D3-R60-260/600-ST-1150 enables double-deep storage of trays in greenhouses.

The telescopic fork for precise transport in the warehouse

Our MINILOAD telescopic fork R32ST-180-N-1250 has a high quality steel design with belt drive. Two belt conveyors enable double-deep storage and retrieval of boxes in the automatic small parts warehouse.

Telescopic fork with belt drive

For our customer, a manufacturer of baby care products, we developed a small, compact MINILOAD telescopic fork in steel design with belt drive, on which the top fork width has been adapted for safe pick-up of the load.

The fast and light among the telescopic forks

Thanks to its compact and at the same time robust aluminum construction, our R38AL230-1250 telescopic fork has a low self-weight. In combination with the belt drive, this offers you the advantage of high dynamic acceleration and speed during your transport processes.

Telescopic fork with rotating centering and lifting device

Miniload special device – Telescopic fork built on a rotating unit, with a load centering unit and a lifting device.